What is Global Plastic Ultrasonic Welder Market?

The Global Plastic Ultrasonic Welder Market refers to the industry focused on the production and sale of ultrasonic welding machines specifically designed for plastic materials. Ultrasonic welding is a process that uses high-frequency ultrasonic acoustic vibrations to create solid-state welds between thermoplastic materials. This technology is widely used because it offers a fast, clean, and reliable method for joining plastic parts without the need for adhesives, solvents, or mechanical fasteners. The market encompasses a variety of ultrasonic welding machines, including both automatic and manual models, which are utilized across numerous industries such as automotive, electronics, medical devices, and packaging. The demand for these machines is driven by the need for efficient and high-quality welding solutions that can meet the stringent requirements of modern manufacturing processes. As industries continue to innovate and develop new plastic products, the Global Plastic Ultrasonic Welder Market is expected to grow, offering advanced solutions to meet the evolving needs of manufacturers worldwide.

Automatic, Manual in the Global Plastic Ultrasonic Welder Market:

In the Global Plastic Ultrasonic Welder Market, there are two primary types of machines: automatic and manual. Automatic ultrasonic welders are designed to operate with minimal human intervention, making them ideal for high-volume production environments. These machines are equipped with advanced features such as programmable logic controllers (PLCs), touch screen interfaces, and automated tooling systems that allow for precise control over the welding process. Automatic welders are often integrated into assembly lines, where they can perform repetitive welding tasks with consistent quality and efficiency. They are particularly useful in industries where speed and accuracy are critical, such as automotive and electronics manufacturing. On the other hand, manual ultrasonic welders require a higher level of human involvement. These machines are typically operated by skilled technicians who manually position the plastic parts and control the welding process. Manual welders are more flexible and can be used for a wide range of applications, including small-batch production and prototyping. They are often preferred in industries where customization and adaptability are important, such as medical device manufacturing and packaging. Both automatic and manual ultrasonic welders offer unique advantages, and the choice between them depends on the specific needs of the application. For instance, in the automotive industry, automatic welders are commonly used for assembling large components like dashboards and door panels, while manual welders may be used for smaller, more intricate parts. In the electronics industry, automatic welders are ideal for producing high volumes of circuit boards and connectors, whereas manual welders can be used for assembling custom electronic devices. In the medical device industry, automatic welders ensure the precision and consistency required for producing critical components like catheters and surgical instruments, while manual welders allow for the flexibility needed to create specialized medical devices. In the packaging industry, automatic welders are used for sealing plastic containers and packaging materials, while manual welders can be employed for creating custom packaging solutions. Overall, the Global Plastic Ultrasonic Welder Market offers a diverse range of machines to meet the varying needs of different industries, providing reliable and efficient welding solutions that enhance the quality and performance of plastic products.

Automotive, Electronic, Medical Device, Packaging, Others in the Global Plastic Ultrasonic Welder Market:

The Global Plastic Ultrasonic Welder Market finds extensive usage across various industries, including automotive, electronics, medical devices, packaging, and others. In the automotive industry, ultrasonic welding is used to assemble a wide range of plastic components, such as dashboards, door panels, and airbag housings. The technology ensures strong and reliable welds, which are essential for the safety and durability of automotive parts. Additionally, ultrasonic welding allows for the integration of different materials, such as plastics and metals, which is crucial for modern automotive designs. In the electronics industry, ultrasonic welding is employed to join plastic housings, connectors, and circuit boards. The process provides a clean and precise method for assembling electronic components, which is vital for maintaining the performance and reliability of electronic devices. Ultrasonic welding also eliminates the need for adhesives and solvents, reducing the risk of contamination and improving the overall quality of electronic products. In the medical device industry, ultrasonic welding is used to manufacture a variety of critical components, such as catheters, surgical instruments, and diagnostic equipment. The technology ensures that medical devices meet stringent regulatory standards for safety and performance. Ultrasonic welding also allows for the creation of hermetic seals, which are essential for preventing contamination and ensuring the sterility of medical devices. In the packaging industry, ultrasonic welding is used to seal plastic containers, blister packs, and flexible packaging materials. The process provides a fast and efficient method for creating strong and leak-proof seals, which are essential for protecting the contents of the packaging. Ultrasonic welding also allows for the use of thinner and more environmentally friendly packaging materials, reducing waste and improving sustainability. Beyond these industries, ultrasonic welding is also used in various other applications, such as the production of consumer goods, textiles, and toys. The technology offers a versatile and reliable method for joining plastic parts, making it an essential tool for manufacturers across a wide range of industries. Overall, the Global Plastic Ultrasonic Welder Market plays a crucial role in modern manufacturing, providing advanced welding solutions that enhance the quality, performance, and sustainability of plastic products.

Global Plastic Ultrasonic Welder Market Outlook:

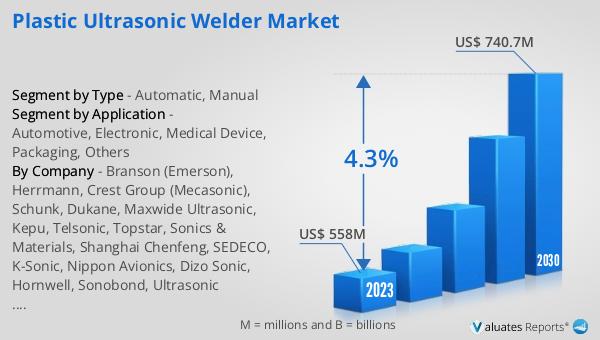

The global Plastic Ultrasonic Welder market was valued at US$ 558 million in 2023 and is anticipated to reach US$ 740.7 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for efficient and high-quality welding solutions across various sectors. The rising adoption of ultrasonic welding technology in industries such as automotive, electronics, medical devices, and packaging is expected to fuel market growth. As manufacturers continue to seek advanced and reliable methods for joining plastic parts, the market for plastic ultrasonic welders is poised to expand. The projected growth reflects the ongoing advancements in ultrasonic welding technology, which offer improved precision, speed, and efficiency. Additionally, the market's expansion is supported by the growing emphasis on sustainability and the need for environmentally friendly manufacturing processes. Overall, the Global Plastic Ultrasonic Welder Market is set to experience significant growth in the coming years, driven by the increasing adoption of ultrasonic welding technology and the continuous development of innovative welding solutions.

| Report Metric | Details |

| Report Name | Plastic Ultrasonic Welder Market |

| Accounted market size in 2023 | US$ 558 million |

| Forecasted market size in 2030 | US$ 740.7 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Branson (Emerson), Herrmann, Crest Group (Mecasonic), Schunk, Dukane, Maxwide Ultrasonic, Kepu, Telsonic, Topstar, Sonics & Materials, Shanghai Chenfeng, SEDECO, K-Sonic, Nippon Avionics, Dizo Sonic, Hornwell, Sonobond, Ultrasonic Engineering Co.,Ltd, Dongho |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |