What is Global Low-Load Collaborative Robot Market?

The Global Low-Load Collaborative Robot Market refers to the industry focused on robots designed to work alongside humans in various tasks, particularly those that involve handling lighter loads. These robots, often called "cobots," are engineered to be safe, flexible, and easy to program, making them ideal for a wide range of applications in different industries. Unlike traditional industrial robots that require safety cages and are programmed for repetitive tasks, low-load collaborative robots can work in close proximity to human workers without posing significant safety risks. They are equipped with advanced sensors and software that allow them to detect and respond to human presence, ensuring a harmonious and efficient collaboration. The market for these robots is growing rapidly as businesses seek to improve productivity, reduce labor costs, and enhance workplace safety. The versatility and adaptability of low-load collaborative robots make them suitable for tasks such as assembly, packaging, quality inspection, and material handling, among others. As technology continues to advance, the capabilities and applications of these robots are expected to expand, driving further growth in the market.

Hardware, Software in the Global Low-Load Collaborative Robot Market:

In the Global Low-Load Collaborative Robot Market, hardware and software components play crucial roles in the functionality and performance of these robots. The hardware aspect includes the physical components of the robot, such as the robotic arm, sensors, actuators, and end-effectors. The robotic arm is designed to be lightweight yet strong enough to handle various tasks, while the sensors provide the robot with the ability to perceive its environment and detect obstacles or human presence. Actuators are responsible for the movement of the robot's joints, enabling precise and smooth operations. End-effectors, which are the tools attached to the end of the robotic arm, can be customized for specific tasks such as gripping, welding, or painting. On the other hand, the software component is equally important as it controls the robot's actions and interactions. Advanced software algorithms enable the robot to learn from its environment, adapt to new tasks, and optimize its performance. This includes machine learning and artificial intelligence capabilities that allow the robot to improve its efficiency over time. The software also includes user-friendly interfaces that make it easy for operators to program and control the robot without needing extensive technical knowledge. Additionally, software updates can be deployed to enhance the robot's capabilities and introduce new features. The integration of hardware and software in low-load collaborative robots ensures that they can perform a wide range of tasks with high precision and reliability. This combination also allows for seamless collaboration between humans and robots, enhancing productivity and safety in various industrial settings. As the market continues to evolve, advancements in both hardware and software are expected to drive further innovation and adoption of low-load collaborative robots.

Moving, Assembly and Disassembly, Welding and Soldering, Dispensing, Machining, Other in the Global Low-Load Collaborative Robot Market:

The usage of Global Low-Load Collaborative Robots spans several key areas, including moving, assembly and disassembly, welding and soldering, dispensing, machining, and other specialized tasks. In the context of moving, these robots are employed to transport materials and products within a facility, reducing the physical strain on human workers and increasing efficiency. They can navigate through complex environments, avoiding obstacles and ensuring the safe delivery of items. In assembly and disassembly, low-load collaborative robots excel in tasks that require precision and consistency. They can assemble small components with high accuracy, reducing the likelihood of errors and improving the overall quality of the final product. Similarly, they can disassemble products for recycling or repair, ensuring that each part is handled carefully. In welding and soldering, these robots provide a high level of precision and control, making them ideal for tasks that require exacting standards. They can perform repetitive welding or soldering operations with consistent quality, reducing the risk of defects and increasing productivity. In dispensing, low-load collaborative robots are used to apply adhesives, sealants, or other materials with precision. This ensures that the right amount of material is applied in the correct location, improving the quality of the final product and reducing waste. In machining, these robots can handle tasks such as drilling, milling, or cutting with high precision. They can work continuously without fatigue, ensuring consistent quality and reducing the need for rework. Other specialized tasks that low-load collaborative robots can perform include inspection, testing, and packaging. They can inspect products for defects, test them for functionality, and package them for shipment, all with a high degree of accuracy and efficiency. The versatility and adaptability of these robots make them valuable assets in a wide range of industries, from manufacturing and logistics to healthcare and electronics.

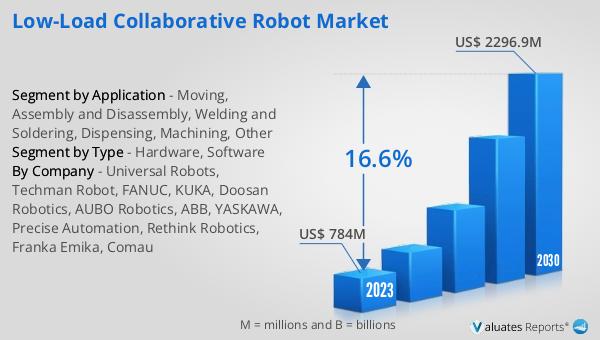

Global Low-Load Collaborative Robot Market Outlook:

The global market for low-load collaborative robots was valued at $784 million in 2023 and is projected to reach $2,296.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 16.6% during the forecast period from 2024 to 2030. This significant growth underscores the increasing demand for these versatile robots across various industries. Businesses are recognizing the benefits of integrating low-load collaborative robots into their operations, including enhanced productivity, improved safety, and reduced labor costs. The ability of these robots to work alongside human workers without the need for extensive safety measures makes them an attractive option for companies looking to optimize their workflows. As technology continues to advance, the capabilities of low-load collaborative robots are expected to expand, further driving their adoption and market growth. The projected market value by 2030 highlights the substantial investment and interest in this sector, indicating a promising future for low-load collaborative robots in the global market.

| Report Metric | Details |

| Report Name | Low-Load Collaborative Robot Market |

| Accounted market size in 2023 | US$ 784 million |

| Forecasted market size in 2030 | US$ 2296.9 million |

| CAGR | 16.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Universal Robots, Techman Robot, FANUC, KUKA, Doosan Robotics, AUBO Robotics, ABB, YASKAWA, Precise Automation, Rethink Robotics, Franka Emika, Comau |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |