What is Global Linear Guide Rail Market?

The Global Linear Guide Rail Market is a specialized segment within the broader industrial machinery and components sector. Linear guide rails are mechanical systems designed to provide smooth and precise linear motion for various applications. These rails are essential in industries that require high accuracy and repeatability, such as manufacturing, automation, and robotics. The market for linear guide rails is driven by the increasing demand for automation and precision in industrial processes. As industries strive for higher efficiency and productivity, the need for reliable and high-performance linear guide systems has grown. The global market encompasses a wide range of products, including ball guide rails, roller guide rails, and needle guide rails, each catering to specific application requirements. The market is characterized by technological advancements, with manufacturers continuously innovating to offer more durable, efficient, and cost-effective solutions. The growth of the market is also influenced by the expansion of industries in emerging economies, where industrialization and automation are on the rise. Overall, the Global Linear Guide Rail Market plays a crucial role in enhancing the performance and efficiency of various industrial applications.

Ball Guide Rail, Roller Guide Rail, Needle Guide Tail, Others in the Global Linear Guide Rail Market:

Ball guide rails, roller guide rails, needle guide rails, and other types of linear guide rails each have unique characteristics and applications within the Global Linear Guide Rail Market. Ball guide rails are the most commonly used type, known for their high precision and smooth motion. They consist of a rail and a carriage with recirculating ball bearings that reduce friction and wear, making them ideal for applications requiring high accuracy and repeatability, such as CNC machines and precision measuring equipment. Roller guide rails, on the other hand, use cylindrical rollers instead of balls, providing higher load capacities and rigidity. This makes them suitable for heavy-duty applications where high stiffness and load-bearing capabilities are essential, such as in large machine tools and industrial robots. Needle guide rails are less common but offer unique advantages in specific applications. They use needle rollers, which are long and thin, providing a larger contact area and higher load capacity in a compact design. This makes them ideal for applications with limited space but requiring high load-bearing capabilities, such as in compact automation equipment and specialized machinery. Other types of linear guide rails include hybrid systems that combine different bearing types to optimize performance for specific applications. These hybrid systems can offer a balance of precision, load capacity, and durability, making them versatile for a wide range of industrial uses. The choice of guide rail type depends on various factors, including the required precision, load capacity, environmental conditions, and specific application needs. Manufacturers in the Global Linear Guide Rail Market continuously innovate to develop new materials, coatings, and designs to enhance the performance and longevity of these systems. For instance, advancements in materials science have led to the development of corrosion-resistant and self-lubricating guide rails, which reduce maintenance requirements and extend the lifespan of the equipment. Additionally, the integration of smart technologies, such as sensors and IoT connectivity, is becoming more prevalent, allowing for real-time monitoring and predictive maintenance of linear guide systems. This not only improves the reliability and efficiency of industrial processes but also reduces downtime and operational costs. Overall, the diverse range of linear guide rail types and the continuous innovation in this market highlight the importance of these components in modern industrial applications.

Automation Equipment, Precision Electronic Machinery, Machine Tool Equipment, Others in the Global Linear Guide Rail Market:

The usage of linear guide rails in automation equipment, precision electronic machinery, machine tool equipment, and other areas is extensive and varied. In automation equipment, linear guide rails are crucial for ensuring precise and repeatable motion, which is essential for tasks such as pick-and-place operations, assembly lines, and robotic arms. The high accuracy and low friction of ball guide rails, in particular, make them ideal for these applications, where even minor deviations can lead to significant errors and inefficiencies. In precision electronic machinery, such as semiconductor manufacturing equipment and electronic assembly machines, linear guide rails provide the necessary precision and stability for handling delicate components and performing intricate tasks. The smooth motion and high load capacity of roller guide rails are particularly beneficial in these applications, where maintaining the integrity of sensitive electronic parts is critical. Machine tool equipment, including CNC machines, lathes, and milling machines, also heavily relies on linear guide rails for accurate and efficient operation. The high rigidity and load-bearing capabilities of roller guide rails make them suitable for these applications, where they must withstand significant forces and maintain precise positioning. Additionally, the use of needle guide rails in compact and specialized machine tools highlights their versatility and ability to meet specific application requirements. Beyond these primary areas, linear guide rails are used in various other industries and applications, such as medical equipment, packaging machinery, and transportation systems. In medical equipment, for example, linear guide rails ensure the precise movement of imaging devices, surgical robots, and patient handling systems, contributing to improved patient outcomes and operational efficiency. In packaging machinery, linear guide rails enable the accurate and efficient movement of products through the packaging process, ensuring consistent quality and reducing waste. In transportation systems, linear guide rails are used in applications such as train doors, sliding seats, and automated storage and retrieval systems, where reliable and smooth motion is essential for safety and efficiency. The versatility and reliability of linear guide rails make them indispensable components in a wide range of industrial applications. As industries continue to advance and demand higher levels of precision and automation, the importance of linear guide rails in ensuring the smooth and efficient operation of machinery and equipment will only continue to grow.

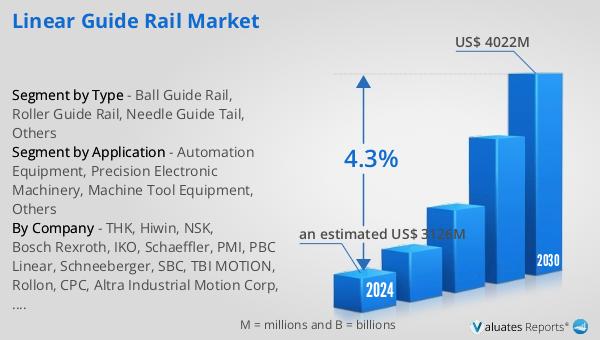

Global Linear Guide Rail Market Outlook:

The global Linear Guide Rail market is anticipated to grow from an estimated US$ 3126 million in 2024 to US$ 4022 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. The market is dominated by the top three players, who collectively hold approximately 76% of the market share. Among the major producers, China Taiwan leads with around 32% of the production share, followed by Japan and China, which hold 26% and 18% of the share, respectively. The largest market for linear guide rails is the Asia-Pacific region, which accounts for about 60% of the global market share. This is followed by Europe and North America, which hold approximately 20% and 15% of the market share, respectively. The significant market share in the Asia-Pacific region can be attributed to the rapid industrialization and increasing adoption of automation technologies in countries such as China, Japan, and South Korea. The strong presence of key manufacturers and the growing demand for high-precision and efficient industrial machinery further drive the market growth in this region. In Europe and North America, the market is driven by the advanced manufacturing sector and the increasing focus on automation and precision engineering. The continuous innovation and development of new materials and technologies by leading manufacturers also contribute to the growth and competitiveness of the global Linear Guide Rail market.

| Report Metric | Details |

| Report Name | Linear Guide Rail Market |

| Accounted market size in 2024 | an estimated US$ 3126 million |

| Forecasted market size in 2030 | US$ 4022 million |

| CAGR | 4.3% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | THK, Hiwin, NSK, Bosch Rexroth, IKO, Schaeffler, PMI, PBC Linear, Schneeberger, SBC, TBI MOTION, Rollon, CPC, Altra Industrial Motion Corp, HTPM, Best Precision, Yigong China, HJMT, DMTG, Sair |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |