What is Global Inline Automated X-ray Inspection Market?

The Global Inline Automated X-ray Inspection Market refers to the industry focused on the development, production, and application of inline automated X-ray inspection systems. These systems are designed to inspect products and components in real-time as they move along a production line. The primary goal is to identify defects, inconsistencies, or foreign objects within the products without interrupting the manufacturing process. This technology is widely used in various industries, including electronics, automotive, aerospace, and medical devices, to ensure high-quality standards and compliance with safety regulations. By providing detailed internal images, these systems help manufacturers detect issues early, reduce waste, and improve overall product quality. The market for these systems is growing due to increasing demand for high-precision inspection and quality control in manufacturing processes.

2D AXI, 3D AXI in the Global Inline Automated X-ray Inspection Market:

2D Automated X-ray Inspection (AXI) and 3D Automated X-ray Inspection (AXI) are two critical technologies within the Global Inline Automated X-ray Inspection Market. 2D AXI systems capture flat, two-dimensional images of the inspected objects. These systems are highly effective for detecting surface-level defects and inconsistencies, such as cracks, voids, and misalignments. They are widely used in industries where surface inspection is crucial, such as printed circuit boards (PCBs) and flat panel displays (FPDs). The primary advantage of 2D AXI is its speed and simplicity, making it suitable for high-volume production lines where quick inspection is essential. On the other hand, 3D AXI systems provide three-dimensional images, offering a more comprehensive view of the inspected objects. These systems can detect both surface and internal defects, making them ideal for complex components like semiconductors and advanced electronic assemblies. 3D AXI systems use advanced imaging techniques, such as computed tomography (CT), to create detailed cross-sectional images, allowing for precise identification of defects that may not be visible in 2D images. While 3D AXI systems are generally more expensive and complex than 2D AXI systems, their ability to provide detailed internal views makes them invaluable for industries requiring high precision and reliability. Both 2D and 3D AXI technologies play a crucial role in ensuring product quality and reliability in various manufacturing sectors.

FPD, PCB, Semiconductor (ex.PCB), Others in the Global Inline Automated X-ray Inspection Market:

The Global Inline Automated X-ray Inspection Market finds extensive usage in several key areas, including Flat Panel Displays (FPD), Printed Circuit Boards (PCB), Semiconductors (excluding PCBs), and other industries. In the FPD sector, inline automated X-ray inspection systems are used to detect defects in the thin layers and intricate structures of display panels. These systems help manufacturers ensure the quality and reliability of displays used in televisions, smartphones, and other electronic devices. In the PCB industry, inline AXI systems are essential for inspecting solder joints, component placements, and internal connections. They help identify issues such as solder voids, bridging, and misalignments, which can affect the performance and reliability of electronic devices. For the semiconductor industry, excluding PCBs, inline AXI systems are used to inspect wafers, integrated circuits, and other semiconductor components. These systems help detect defects such as cracks, voids, and delaminations, ensuring the quality and performance of semiconductor devices used in various applications, including computers, smartphones, and automotive electronics. Additionally, inline AXI systems are used in other industries, such as automotive, aerospace, and medical devices, to inspect critical components and ensure compliance with safety and quality standards. By providing real-time, high-precision inspection, these systems help manufacturers improve product quality, reduce waste, and enhance overall production efficiency.

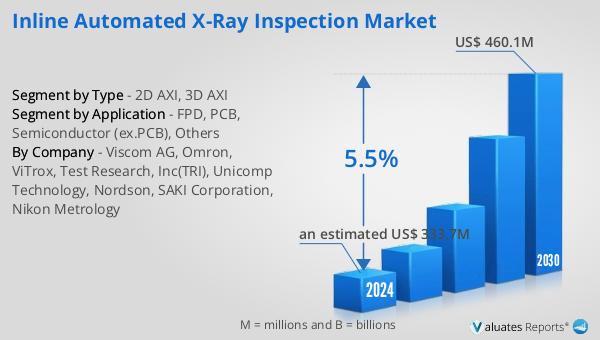

Global Inline Automated X-ray Inspection Market Outlook:

The global Inline Automated X-ray Inspection market is anticipated to grow significantly, with projections indicating it will reach US$ 460.1 million by 2030, up from an estimated US$ 333.7 million in 2024. This growth represents a compound annual growth rate (CAGR) of 5.5% during the period from 2024 to 2030. In 2019, the top three manufacturers in this market held approximately 41.22% of the market share, highlighting the competitive nature of the industry. The increasing demand for high-precision inspection and quality control in various manufacturing sectors is driving this growth. Inline automated X-ray inspection systems are becoming essential tools for manufacturers aiming to ensure product quality, reduce waste, and comply with stringent safety and regulatory standards. As industries continue to adopt advanced manufacturing technologies, the demand for efficient and reliable inspection systems is expected to rise, further fueling the growth of the global Inline Automated X-ray Inspection market.

| Report Metric | Details |

| Report Name | Inline Automated X-ray Inspection Market |

| Accounted market size in 2024 | an estimated US$ 333.7 million |

| Forecasted market size in 2030 | US$ 460.1 million |

| CAGR | 5.5% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Viscom AG, Omron, ViTrox, Test Research, Inc(TRI), Unicomp Technology, Nordson, SAKI Corporation, Nikon Metrology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |