What is Global Injection Molding Machine Market?

The global Injection Molding Machine market is a dynamic and essential segment of the manufacturing industry. Injection molding machines are used to produce a wide variety of plastic parts by injecting molten plastic into a mold, where it cools and solidifies into the desired shape. These machines are crucial in the production of everyday items ranging from simple household goods to complex automotive components. The market for these machines is driven by the increasing demand for plastic products across various industries, including automotive, electronics, medical, and consumer goods. Technological advancements in injection molding machines, such as improved precision, energy efficiency, and automation, are also contributing to market growth. The global market is highly competitive, with numerous players striving to innovate and offer cost-effective solutions to meet the diverse needs of their customers. The market's expansion is further supported by the growing trend of lightweight and durable plastic components, which are increasingly replacing traditional materials like metal and glass.

Clamping Force: Below 250T, Clamping Force: 250-650T, Clamping Force: 650-1000T, Clamping Force: 650-1000TT, Clamping Force: Above 2000T in the Global Injection Molding Machine Market:

Clamping force is a critical parameter in the global injection molding machine market, determining the machine's ability to hold the mold closed during the injection process. Machines with a clamping force below 250T are typically used for producing small and intricate parts, such as those found in electronics and medical devices. These machines are favored for their precision and ability to handle delicate materials without causing damage. Machines with a clamping force between 250-650T are versatile and widely used across various industries, including automotive and consumer goods. They offer a balance between power and precision, making them suitable for producing medium-sized parts with complex geometries. Machines with a clamping force between 650-1000T are designed for larger and more demanding applications, such as automotive components and large household appliances. These machines provide the necessary force to mold large parts with high accuracy and consistency. Machines with a clamping force above 2000T are used for the most demanding applications, including large automotive parts, industrial containers, and heavy-duty equipment. These machines are capable of handling high-volume production runs and producing parts with exceptional strength and durability. The choice of clamping force depends on the specific requirements of the application, including the size, complexity, and material of the part being produced. Manufacturers must carefully consider these factors to select the appropriate machine that meets their production needs while ensuring efficiency and cost-effectiveness.

Commodity, Automobile, Home Appliance, 3C Electronics, Medical, Logistics, Others in the Global Injection Molding Machine Market:

The global injection molding machine market finds extensive usage across various sectors, each with unique requirements and applications. In the commodity sector, these machines are used to produce everyday plastic items such as packaging materials, containers, and disposable products. The ability to produce high volumes of consistent and cost-effective parts makes injection molding machines indispensable in this sector. In the automotive industry, injection molding machines are used to manufacture a wide range of components, including dashboards, bumpers, and interior trims. The precision and durability of these machines ensure that automotive parts meet stringent quality and safety standards. In the home appliance sector, injection molding machines are used to produce parts for refrigerators, washing machines, and other household devices. The machines' ability to create complex shapes and designs allows manufacturers to innovate and improve the functionality and aesthetics of their products. In the 3C electronics sector, which includes computers, communications, and consumer electronics, injection molding machines are used to produce casings, connectors, and other small components. The high precision and repeatability of these machines are crucial for meeting the tight tolerances required in electronic devices. In the medical sector, injection molding machines are used to produce a variety of medical devices and components, such as syringes, surgical instruments, and diagnostic equipment. The machines' ability to produce sterile and high-quality parts is essential for ensuring patient safety and compliance with regulatory standards. In the logistics sector, injection molding machines are used to produce pallets, crates, and other storage and transportation solutions. The durability and strength of the molded parts are critical for withstanding the rigors of handling and shipping. Other sectors, such as aerospace, construction, and consumer goods, also rely on injection molding machines for producing specialized parts and components. The versatility and efficiency of these machines make them a valuable asset in various industries, driving innovation and improving product quality.

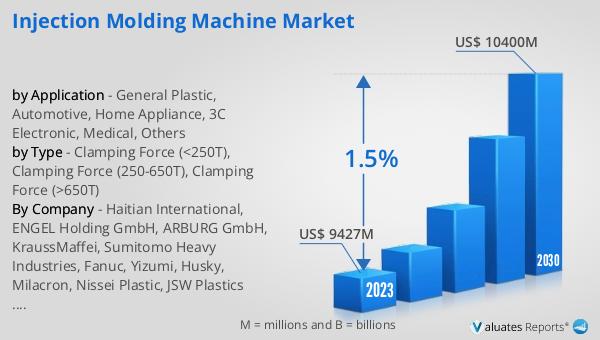

Global Injection Molding Machine Market Outlook:

The global Injection Molding Machine market is anticipated to grow, reaching approximately US$ 12,550 million by 2030, up from an estimated US$ 11,780 million in 2024, with a compound annual growth rate (CAGR) of 1.1% between 2024 and 2030. The top five companies in this market collectively hold about 50% of the market share. The Asia-Pacific region dominates the market with a share of around 65%, followed by Europe and North America, which hold approximately 20% and 5% of the market share, respectively. In terms of product segmentation, machines with a clamping force of 250-650T represent the largest segment, accounting for over 45% of the market share. This segment's dominance is attributed to its versatility and wide range of applications across various industries, making it a preferred choice for many manufacturers. The market's growth is driven by the increasing demand for plastic products, technological advancements in injection molding machines, and the growing trend of lightweight and durable plastic components.

| Report Metric | Details |

| Report Name | Injection Molding Machine Market |

| Accounted market size in 2024 | an estimated US$ 11780 million |

| Forecasted market size in 2030 | US$ 12550 million |

| CAGR | 1.1% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Haitian International, ENGEL Holding GmbH, KraussMaffei, ARBURG GmbH, Fanuc, Husky, Milacron, Sumitomo Heavy Industries, Shibaura Machine, Nissei Plastic, JSW Plastics Machinery, Wittmann Battenfeld, Chen Hsong Injection Molding Machinery, Toyo, Guangdong Yizumi Precision Machinery Co.,Ltd., UBE Machinery, L.K. Technology Holdings Limited, Cosmos Machinery, TEDERIC Machinery, Windsor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |