What is Global Industrial Rust Inhibitors Market?

The Global Industrial Rust Inhibitors Market refers to the worldwide industry focused on the production and distribution of chemicals and coatings designed to prevent rust and corrosion on metal surfaces. These inhibitors are crucial in extending the lifespan of machinery, vehicles, infrastructure, and various industrial equipment by protecting them from the damaging effects of moisture, oxygen, and other corrosive elements. The market encompasses a wide range of products, including solvent-based, water-based, and oil-based inhibitors, each tailored to specific applications and industries. The demand for rust inhibitors is driven by the need to maintain the integrity and functionality of metal components in sectors such as automotive, construction, marine, and manufacturing. As industries continue to expand and modernize, the importance of rust prevention becomes increasingly significant, leading to a growing market for these protective solutions. The global industrial rust inhibitors market is characterized by ongoing research and development efforts aimed at improving the effectiveness and environmental sustainability of these products.

Solvent-based Industrial Rust Inhibitor, Water-based Industrial Rust Inhibitor in the Global Industrial Rust Inhibitors Market:

Solvent-based industrial rust inhibitors are a type of rust prevention solution that utilizes organic solvents as the primary medium for delivering active anti-corrosion agents. These inhibitors are particularly effective in providing a robust protective layer on metal surfaces, making them ideal for heavy-duty applications where exposure to harsh environmental conditions is common. Solvent-based inhibitors are known for their quick drying times and strong adhesion properties, which ensure long-lasting protection. They are widely used in industries such as automotive, aerospace, and marine, where metal components are frequently exposed to moisture, salt, and other corrosive elements. However, the use of organic solvents raises environmental and health concerns due to the emission of volatile organic compounds (VOCs), which can contribute to air pollution and pose risks to human health. As a result, there is a growing trend towards developing low-VOC or VOC-free solvent-based rust inhibitors to address these issues. On the other hand, water-based industrial rust inhibitors use water as the primary solvent, making them a more environmentally friendly alternative to their solvent-based counterparts. These inhibitors are designed to provide effective rust protection while minimizing the environmental impact associated with VOC emissions. Water-based inhibitors are typically easier to apply and clean up, and they offer good compatibility with a wide range of metal surfaces. They are commonly used in industries such as construction, manufacturing, and transportation, where there is a need for effective rust prevention without compromising environmental and worker safety. Despite their advantages, water-based inhibitors may have limitations in terms of drying time and durability compared to solvent-based products. However, ongoing advancements in formulation technology are helping to bridge this gap, making water-based rust inhibitors increasingly competitive in the market. Both solvent-based and water-based rust inhibitors play a crucial role in the global industrial rust inhibitors market, catering to the diverse needs of various industries while balancing performance and environmental considerations.

Industrial, Traffic, Others in the Global Industrial Rust Inhibitors Market:

The usage of global industrial rust inhibitors spans across various sectors, including industrial, traffic, and others, each with its unique requirements and challenges. In the industrial sector, rust inhibitors are essential for maintaining the integrity and performance of machinery, equipment, and infrastructure. Industries such as manufacturing, oil and gas, and power generation rely heavily on metal components that are susceptible to corrosion. Rust inhibitors help prevent the degradation of these components, ensuring operational efficiency and reducing maintenance costs. For example, in manufacturing plants, rust inhibitors are used to protect conveyor systems, metal parts, and storage tanks from rust, thereby extending their service life and minimizing downtime. In the oil and gas industry, rust inhibitors are crucial for protecting pipelines, drilling equipment, and storage tanks from the corrosive effects of harsh environmental conditions and chemical exposure. In the traffic sector, rust inhibitors play a vital role in maintaining the safety and longevity of vehicles and infrastructure. Automotive manufacturers use rust inhibitors to protect car bodies, chassis, and other metal parts from rust, which can compromise the structural integrity and safety of vehicles. Similarly, rust inhibitors are used in the maintenance of bridges, guardrails, and traffic signs to prevent corrosion and ensure the safety and durability of transportation infrastructure. The use of rust inhibitors in the traffic sector helps reduce repair and replacement costs, improve safety, and extend the lifespan of vehicles and infrastructure. Beyond the industrial and traffic sectors, rust inhibitors find applications in various other areas, including marine, aerospace, and household products. In the marine industry, rust inhibitors are used to protect ships, offshore platforms, and other marine structures from the corrosive effects of saltwater and harsh marine environments. In the aerospace industry, rust inhibitors are essential for protecting aircraft components from corrosion, ensuring the safety and reliability of air travel. Additionally, rust inhibitors are used in household products such as tools, appliances, and outdoor furniture to prevent rust and extend their lifespan. The diverse applications of rust inhibitors across different sectors highlight their importance in preserving the functionality, safety, and longevity of metal components and structures.

Global Industrial Rust Inhibitors Market Outlook:

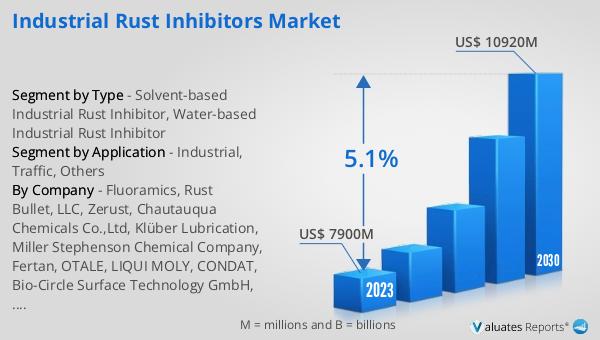

The global industrial rust inhibitors market was valued at $7.9 billion in 2023 and is projected to reach $10.92 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for rust prevention solutions across various industries, including automotive, construction, marine, and manufacturing. As industries continue to expand and modernize, the need to protect metal components from corrosion becomes more critical, leading to a growing market for rust inhibitors. The market is characterized by ongoing research and development efforts aimed at improving the effectiveness and environmental sustainability of rust inhibitors. Innovations in formulation technology are helping to create more efficient and eco-friendly products, addressing the environmental and health concerns associated with traditional solvent-based inhibitors. Additionally, the rising awareness of the economic benefits of rust prevention, such as reduced maintenance costs and extended equipment lifespan, is further fueling the demand for rust inhibitors. The global industrial rust inhibitors market is poised for significant growth, driven by the increasing need for effective rust prevention solutions in various industries and the continuous advancements in product technology.

| Report Metric | Details |

| Report Name | Industrial Rust Inhibitors Market |

| Accounted market size in 2023 | US$ 7900 in million |

| Forecasted market size in 2030 | US$ 10920 million |

| CAGR | 5.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fluoramics, Rust Bullet, LLC, Zerust, Chautauqua Chemicals Co.,Ltd, Klüber Lubrication, Miller Stephenson Chemical Company, Fertan, OTALE, LIQUI MOLY, CONDAT, Bio-Circle Surface Technology GmbH, FUCHS, Morris Lubricants, IKV Tribology Ltd, Amo Xincailiaojishu, Hengsheng Xincailiao, Kaidina, Hengxing Keji, Longhai Shihua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |