What is Global Glass Felt Thermoplastic Resin Market?

The Global Glass Felt Thermoplastic Resin Market refers to the industry focused on the production and distribution of thermoplastic resins reinforced with glass felt. These materials are known for their excellent mechanical properties, including high strength, durability, and resistance to heat and chemicals. Glass felt thermoplastic resins are used in various applications across multiple industries due to their lightweight nature and ability to be molded into complex shapes. The market for these materials is driven by the increasing demand for high-performance, lightweight materials in sectors such as automotive, aerospace, electronics, and consumer goods. As industries continue to seek materials that offer both performance and sustainability, the Global Glass Felt Thermoplastic Resin Market is expected to grow, driven by advancements in manufacturing technologies and the development of new applications.

Short Fiber Thermoplastic, Long Fiber Thermoplastic in the Global Glass Felt Thermoplastic Resin Market:

Short Fiber Thermoplastic (SFT) and Long Fiber Thermoplastic (LFT) are two key types of materials within the Global Glass Felt Thermoplastic Resin Market. SFTs are composed of short glass fibers, typically less than 1 millimeter in length, which are mixed with thermoplastic resins to enhance their mechanical properties. These materials are known for their ease of processing, making them suitable for high-volume production methods such as injection molding. SFTs are commonly used in applications where complex shapes and fine details are required, such as in automotive components, consumer electronics, and small household appliances. Their ability to be easily molded and their cost-effectiveness make them a popular choice for manufacturers looking to produce lightweight, durable parts. On the other hand, Long Fiber Thermoplastics (LFTs) contain longer glass fibers, usually ranging from 10 to 25 millimeters in length. The longer fibers provide superior mechanical properties compared to SFTs, including higher strength, stiffness, and impact resistance. LFTs are often used in applications that require enhanced performance, such as structural components in the automotive and aerospace industries. The longer fibers in LFTs create a more robust material that can withstand higher loads and stresses, making them ideal for parts that need to endure harsh conditions and heavy use. Additionally, LFTs offer better dimensional stability and lower warpage, which is crucial for maintaining the integrity of parts over time. Both SFTs and LFTs play a significant role in the Global Glass Felt Thermoplastic Resin Market, each catering to different needs and applications. The choice between SFT and LFT depends on the specific requirements of the application, including the desired mechanical properties, processing methods, and cost considerations. As industries continue to innovate and develop new products, the demand for both types of thermoplastic resins is expected to grow, driven by the need for high-performance, lightweight materials that can meet the demands of modern manufacturing.

Transport, Consumer Goods, Electronic and Electrical, Aerospace and Defense, Other in the Global Glass Felt Thermoplastic Resin Market:

The usage of Global Glass Felt Thermoplastic Resin Market spans across various industries, including transport, consumer goods, electronic and electrical, aerospace and defense, and others. In the transport sector, these materials are widely used in the production of automotive components such as bumpers, dashboards, and interior panels. The lightweight nature of glass felt thermoplastic resins helps reduce the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. Additionally, their high strength and durability ensure that automotive parts can withstand the rigors of daily use and harsh environmental conditions. In the consumer goods industry, glass felt thermoplastic resins are used to manufacture a wide range of products, including household appliances, sports equipment, and furniture. The materials' ability to be easily molded into complex shapes allows for the creation of aesthetically pleasing and functional products. Their resistance to heat and chemicals also makes them ideal for use in kitchen appliances and other household items that are exposed to high temperatures and harsh cleaning agents. The electronic and electrical industry also benefits from the use of glass felt thermoplastic resins. These materials are used in the production of electronic housings, connectors, and other components that require high precision and durability. The insulating properties of thermoplastic resins make them suitable for use in electrical applications, where they help protect sensitive electronic components from damage and ensure the safe operation of devices. In the aerospace and defense sectors, glass felt thermoplastic resins are used to manufacture structural components, interior panels, and other parts that require high strength and lightweight properties. The materials' ability to withstand extreme temperatures and harsh environmental conditions makes them ideal for use in aircraft and military vehicles. Additionally, their lightweight nature helps reduce the overall weight of aircraft, leading to improved fuel efficiency and performance. Other industries that utilize glass felt thermoplastic resins include construction, medical devices, and packaging. In construction, these materials are used to produce durable and lightweight building materials, such as roofing panels and insulation. In the medical field, they are used to manufacture medical devices and equipment that require high precision and durability. In packaging, glass felt thermoplastic resins are used to create lightweight and durable packaging materials that protect products during transportation and storage.

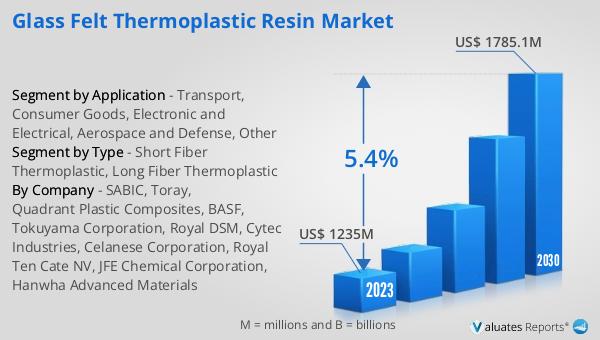

Global Glass Felt Thermoplastic Resin Market Outlook:

The global Glass Felt Thermoplastic Resin market was valued at US$ 1235 million in 2023 and is anticipated to reach US$ 1785.1 million by 2030, witnessing a CAGR of 5.4% during the forecast period from 2024 to 2030. This market growth is driven by the increasing demand for high-performance, lightweight materials across various industries. As manufacturers continue to seek materials that offer both performance and sustainability, the market for glass felt thermoplastic resins is expected to expand. The advancements in manufacturing technologies and the development of new applications are also contributing to the growth of this market.

| Report Metric | Details |

| Report Name | Glass Felt Thermoplastic Resin Market |

| Accounted market size in 2023 | US$ 1235 million |

| Forecasted market size in 2030 | US$ 1785.1 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SABIC, Toray, Quadrant Plastic Composites, BASF, Tokuyama Corporation, Royal DSM, Cytec Industries, Celanese Corporation, Royal Ten Cate NV, JFE Chemical Corporation, Hanwha Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |