What is Global FPC EMI Shielding Film Market?

The Global FPC EMI Shielding Film Market refers to the market for films used to shield flexible printed circuits (FPCs) from electromagnetic interference (EMI). These films are crucial in ensuring that electronic devices function properly by preventing unwanted electromagnetic signals from interfering with the circuits. EMI shielding films are used in various applications, including smartphones, tablets, laptops, and other electronic devices that require flexible circuits. The market is driven by the increasing demand for electronic devices and the need for better performance and reliability. As technology advances, the need for effective EMI shielding solutions becomes more critical, making the Global FPC EMI Shielding Film Market an essential component of the electronics industry.

Conductive Adhesive Type, Metal Alloy Type, Metal Microneedle Type in the Global FPC EMI Shielding Film Market:

Conductive Adhesive Type, Metal Alloy Type, and Metal Microneedle Type are three significant categories within the Global FPC EMI Shielding Film Market. Conductive Adhesive Type films use adhesives that contain conductive materials, such as silver or carbon, to create a shield against EMI. These adhesives are applied to the surface of the FPC, forming a conductive layer that blocks electromagnetic signals. This type is popular due to its ease of application and flexibility, making it suitable for various electronic devices. Metal Alloy Type films, on the other hand, use thin layers of metal alloys, such as copper or aluminum, to provide EMI shielding. These films are known for their excellent conductivity and durability, making them ideal for high-performance applications. The metal alloy layer is typically laminated onto the FPC, creating a robust shield that can withstand harsh environments. Metal Microneedle Type films are a more advanced solution, utilizing tiny metal needles embedded in the film to create a conductive path. These microneedles penetrate the surface of the FPC, forming a highly effective shield against EMI. This type is particularly useful in applications where space is limited, and a high level of precision is required. Each of these types offers unique advantages, catering to different needs within the electronics industry. The choice of shielding film depends on factors such as the specific application, performance requirements, and environmental conditions. As the demand for more sophisticated electronic devices grows, the need for advanced EMI shielding solutions like these continues to rise, driving innovation and development in the Global FPC EMI Shielding Film Market.

Single-sided Circuit, Double-sided Circuit, Multi-layer Circuit, Rigid-Flex Circuit in the Global FPC EMI Shielding Film Market:

The usage of Global FPC EMI Shielding Film Market in Single-sided Circuit, Double-sided Circuit, Multi-layer Circuit, and Rigid-Flex Circuit varies based on the specific requirements of each application. Single-sided Circuits are the simplest form of FPCs, with components mounted on one side of the circuit. EMI shielding films used in these circuits need to provide effective protection without adding significant bulk or weight. Conductive Adhesive Type films are often preferred for single-sided circuits due to their flexibility and ease of application. Double-sided Circuits have components mounted on both sides, requiring more robust EMI shielding solutions. Metal Alloy Type films are commonly used in double-sided circuits because of their excellent conductivity and durability. These films can provide a strong shield against EMI while maintaining the flexibility needed for FPCs. Multi-layer Circuits are more complex, with multiple layers of circuits stacked together. EMI shielding in multi-layer circuits is critical to prevent interference between the layers. Metal Microneedle Type films are particularly effective in these applications, as they can penetrate multiple layers and provide a highly conductive path for shielding. Rigid-Flex Circuits combine the benefits of both rigid and flexible circuits, offering a versatile solution for complex electronic devices. EMI shielding films used in rigid-flex circuits need to be highly adaptable to accommodate the varying shapes and sizes of the circuits. Conductive Adhesive Type and Metal Alloy Type films are both suitable for rigid-flex circuits, depending on the specific requirements of the application. The choice of EMI shielding film for each type of circuit depends on factors such as the level of EMI protection needed, the complexity of the circuit, and the environmental conditions. As electronic devices become more advanced and compact, the demand for effective EMI shielding solutions in these various types of circuits continues to grow, driving innovation and development in the Global FPC EMI Shielding Film Market.

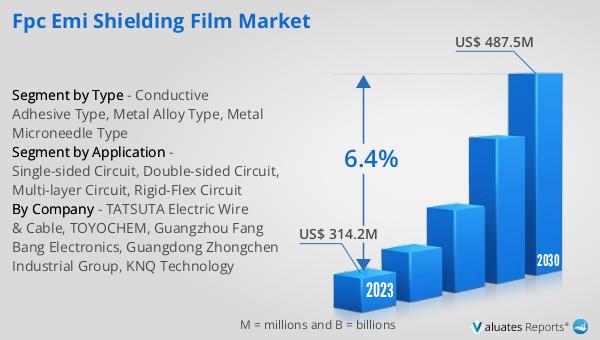

Global FPC EMI Shielding Film Market Outlook:

The global FPC EMI Shielding Film market is anticipated to grow significantly, reaching approximately US$ 487.5 million by 2030, up from an estimated US$ 336 million in 2024, reflecting a compound annual growth rate (CAGR) of 6.4% during the period from 2024 to 2030. TATSUTA Electric Wire & Cable emerged as the leading vendor in this market, holding over 50% of the market share in 2018. This growth is driven by the increasing demand for electronic devices and the need for effective EMI shielding solutions to ensure their proper functioning. The market's expansion is also fueled by advancements in technology and the development of more sophisticated electronic devices that require reliable EMI protection. As the electronics industry continues to evolve, the importance of EMI shielding films in maintaining the performance and reliability of electronic devices becomes more critical. The dominance of TATSUTA Electric Wire & Cable in the market highlights the company's expertise and strong position in providing high-quality EMI shielding solutions. With the ongoing advancements in electronic devices and the growing need for effective EMI protection, the Global FPC EMI Shielding Film Market is expected to continue its upward trajectory, offering numerous opportunities for growth and innovation.

| Report Metric | Details |

| Report Name | FPC EMI Shielding Film Market |

| Accounted market size in 2024 | an estimated US$ 336 million |

| Forecasted market size in 2030 | US$ 487.5 million |

| CAGR | 6.4% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | TATSUTA Electric Wire & Cable, TOYOCHEM, Guangzhou Fang Bang Electronics, Guangdong Zhongchen Industrial Group, KNQ Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |