What is Global Fiberglass Reinforced Plastic Chemical Storage Tanks Market?

The Global Fiberglass Reinforced Plastic (FRP) Chemical Storage Tanks Market is a specialized segment within the broader chemical storage industry. These tanks are designed to store various chemicals safely and efficiently, leveraging the unique properties of fiberglass reinforced plastic. FRP tanks are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for storing aggressive chemicals that would otherwise degrade traditional storage materials like steel or concrete. The market for these tanks is driven by the increasing demand for safe and reliable chemical storage solutions across various industries, including chemicals, oil and gas, wastewater treatment, and more. As industries continue to expand and the need for safe chemical storage grows, the demand for FRP chemical storage tanks is expected to rise. These tanks are available in various sizes and capacities to meet the diverse needs of different applications, making them a versatile choice for many businesses.

By Capacity, Less Than 5000 Litres, 5000-10000 Litres, More Than 10000 Litres in the Global Fiberglass Reinforced Plastic Chemical Storage Tanks Market:

When it comes to the capacity of Global Fiberglass Reinforced Plastic Chemical Storage Tanks, they are generally categorized into three main segments: less than 5000 liters, 5000-10000 liters, and more than 10000 liters. Tanks with a capacity of less than 5000 liters are typically used for smaller-scale applications or in industries where space is a constraint. These smaller tanks are often employed in laboratories, small manufacturing units, or for storing smaller quantities of chemicals that do not require large storage solutions. They are easy to handle, install, and maintain, making them a popular choice for businesses with limited storage needs. On the other hand, tanks with a capacity of 5000-10000 liters are more suited for medium-scale operations. These tanks strike a balance between storage capacity and space efficiency, making them ideal for mid-sized manufacturing units, chemical processing plants, and other industrial applications. They offer a good compromise between the need for substantial storage and the practicalities of installation and maintenance. Finally, tanks with a capacity of more than 10000 liters are designed for large-scale industrial applications. These tanks are often used in large manufacturing plants, oil refineries, wastewater treatment facilities, and other industries that require significant storage capacity. They are built to withstand harsh environmental conditions and the corrosive nature of the chemicals they store, ensuring long-term durability and reliability. The choice of tank capacity depends largely on the specific needs of the application, the volume of chemicals to be stored, and the available space for installation. Each capacity segment has its own set of advantages and is designed to meet the unique requirements of different industries.

Ordinary Chemical, Fuel and Oil, Wastewater, Others in the Global Fiberglass Reinforced Plastic Chemical Storage Tanks Market:

The usage of Global Fiberglass Reinforced Plastic Chemical Storage Tanks spans across various sectors, including ordinary chemicals, fuel and oil, wastewater, and others. In the ordinary chemical sector, these tanks are used to store a wide range of chemicals, including acids, alkalis, solvents, and other corrosive substances. The corrosion-resistant properties of FRP make these tanks ideal for storing chemicals that would otherwise degrade traditional storage materials. In the fuel and oil sector, FRP tanks are used to store various types of fuels, including gasoline, diesel, and aviation fuel. The high strength-to-weight ratio of FRP makes these tanks suitable for storing large volumes of fuel without the risk of leakage or structural failure. Additionally, the non-corrosive nature of FRP ensures that the stored fuel remains uncontaminated, maintaining its quality over time. In the wastewater sector, FRP tanks are used to store and treat wastewater from various industrial processes. These tanks are designed to withstand the harsh conditions associated with wastewater treatment, including exposure to corrosive chemicals and extreme temperatures. The durability and corrosion resistance of FRP make these tanks a reliable choice for long-term wastewater storage and treatment. Other sectors that utilize FRP chemical storage tanks include food and beverage, pharmaceuticals, and agriculture. In the food and beverage industry, these tanks are used to store ingredients and finished products, ensuring that they remain uncontaminated and safe for consumption. In the pharmaceutical industry, FRP tanks are used to store raw materials and finished products, maintaining their purity and quality. In agriculture, these tanks are used to store fertilizers, pesticides, and other chemicals, ensuring that they remain effective and safe for use. Overall, the versatility and durability of FRP chemical storage tanks make them a valuable asset across various industries, providing safe and reliable storage solutions for a wide range of applications.

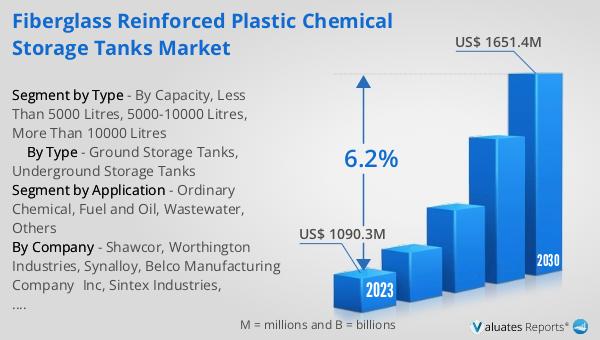

Global Fiberglass Reinforced Plastic Chemical Storage Tanks Market Outlook:

The global Fiberglass Reinforced Plastic Chemical Storage Tanks market was valued at US$ 1090.3 million in 2023 and is anticipated to reach US$ 1651.4 million by 2030 witnessing a CAGR of 6.2% during the forecast period 2024-2030. This market outlook indicates a robust growth trajectory for the FRP chemical storage tanks market, driven by increasing demand for safe and reliable chemical storage solutions across various industries. The market's growth is attributed to the unique properties of FRP, including its high strength-to-weight ratio, corrosion resistance, and durability, which make it an ideal material for chemical storage tanks. As industries continue to expand and the need for safe chemical storage grows, the demand for FRP chemical storage tanks is expected to rise. The market's growth is also supported by advancements in manufacturing technologies, which have made it possible to produce high-quality FRP tanks at competitive prices. Additionally, stringent regulations regarding chemical storage and environmental protection are driving the adoption of FRP tanks, as they offer a safe and reliable solution for storing hazardous chemicals. Overall, the market outlook for FRP chemical storage tanks is positive, with significant growth expected in the coming years.

| Report Metric | Details |

| Report Name | Fiberglass Reinforced Plastic Chemical Storage Tanks Market |

| Accounted market size in 2023 | US$ 1090.3 million |

| Forecasted market size in 2030 | US$ 1651.4 million |

| CAGR | 6.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| By Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shawcor, Worthington Industries, Synalloy, Belco Manufacturing Company,Inc, Sintex Industries, Chemstore Group, LF Manufacturing, Red Ewald, TF Warren(Tarsco), JRMS Engineering Works, Aeron Composite Private Limited, CECO, Augusta Fiberglass Coatings,Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |