What is Global Ductile Cast Iron Market?

The Global Ductile Cast Iron Market refers to the worldwide industry involved in the production and distribution of ductile cast iron, a type of cast iron known for its excellent strength, durability, and resistance to wear and tear. Ductile cast iron, also known as nodular cast iron, is characterized by its unique microstructure, which includes spherical graphite nodules that enhance its mechanical properties. This material is widely used in various industries due to its superior performance compared to traditional cast iron. The market encompasses a range of activities, from raw material extraction and processing to the manufacturing of finished products and their distribution to end-users. The demand for ductile cast iron is driven by its applications in sectors such as automotive, construction, machinery, oil and gas, and aerospace, among others. As industries continue to seek materials that offer a balance of strength, flexibility, and cost-effectiveness, the global ductile cast iron market is expected to grow steadily.

Vertical Molding, Horizontal Molding in the Global Ductile Cast Iron Market:

Vertical molding and horizontal molding are two primary methods used in the production of ductile cast iron, each with its own set of advantages and applications. Vertical molding involves the use of vertically oriented molds, which are filled with molten iron from the top. This method is particularly advantageous for producing large quantities of castings with consistent quality and dimensional accuracy. The vertical orientation allows for efficient use of space and facilitates the rapid cooling of the molten iron, resulting in castings with fine-grained microstructures and enhanced mechanical properties. Vertical molding is commonly used in the automotive industry for manufacturing engine blocks, cylinder heads, and other critical components that require high strength and durability. On the other hand, horizontal molding involves the use of horizontally oriented molds, which are filled with molten iron from the side. This method is well-suited for producing complex shapes and intricate designs, as the horizontal orientation allows for greater flexibility in mold design and casting geometry. Horizontal molding is often used in the machinery and equipment industry for producing gears, housings, and other components that require precise dimensions and intricate details. Both vertical and horizontal molding techniques play a crucial role in the global ductile cast iron market, catering to the diverse needs of various industries and ensuring the production of high-quality castings that meet stringent performance standards.

Machinery & Equipment, Automotive, Construction, Oil and Gas, Aerospace, Others in the Global Ductile Cast Iron Market:

The global ductile cast iron market finds extensive usage across various industries, including machinery and equipment, automotive, construction, oil and gas, aerospace, and others. In the machinery and equipment sector, ductile cast iron is used to manufacture components such as gears, housings, and machine frames, which require high strength, durability, and resistance to wear and tear. The material's excellent mechanical properties make it ideal for applications where reliability and longevity are critical. In the automotive industry, ductile cast iron is widely used for producing engine blocks, cylinder heads, crankshafts, and other critical components that need to withstand high stress and temperature conditions. Its superior strength and thermal conductivity ensure optimal performance and efficiency of automotive engines. In the construction industry, ductile cast iron is used for making pipes, fittings, and structural components that require high load-bearing capacity and resistance to corrosion. The material's robustness and durability make it suitable for infrastructure projects such as bridges, buildings, and pipelines. In the oil and gas industry, ductile cast iron is used for manufacturing valves, pumps, and other equipment that operate in harsh environments and require high resistance to pressure and corrosion. Its ability to withstand extreme conditions ensures the reliability and safety of oil and gas operations. In the aerospace industry, ductile cast iron is used for producing components such as landing gear, engine mounts, and structural parts that require high strength-to-weight ratio and resistance to fatigue. The material's excellent mechanical properties and lightweight nature make it suitable for aerospace applications where performance and safety are paramount. Additionally, ductile cast iron is used in other industries such as agriculture, mining, and marine, where its versatility and durability offer significant advantages. Overall, the global ductile cast iron market plays a vital role in supporting the diverse needs of various industries, providing high-quality materials that enhance the performance, reliability, and longevity of critical components and systems.

Global Ductile Cast Iron Market Outlook:

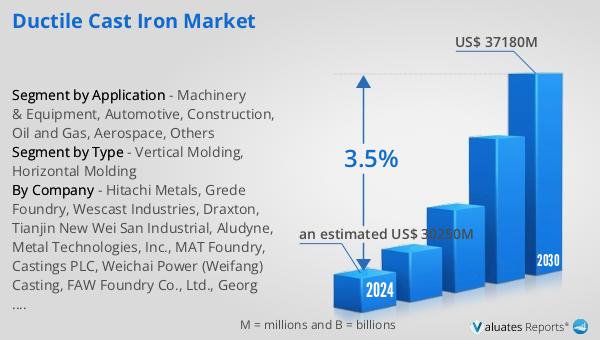

The global ductile cast iron market is anticipated to grow significantly, with projections indicating it will reach approximately US$ 37,180 million by 2030, up from an estimated US$ 30,250 million in 2024, reflecting a compound annual growth rate (CAGR) of 3.5% during the period from 2024 to 2030. The market is dominated by the top three players, who collectively hold about 35% of the market share. Vertical molding is the predominant type of molding used in this market, accounting for around 65% of the total share. This method is favored due to its efficiency and ability to produce high-quality castings with consistent properties. The automotive sector is the largest application area for ductile cast iron, holding approximately 30% of the market share. This is due to the material's superior strength, durability, and thermal conductivity, which are essential for manufacturing critical automotive components such as engine blocks, cylinder heads, and crankshafts. The steady growth of the global ductile cast iron market is driven by the increasing demand for high-performance materials across various industries, as well as advancements in molding technologies that enhance the quality and efficiency of ductile cast iron production.

| Report Metric | Details |

| Report Name | Ductile Cast Iron Market |

| Accounted market size in 2024 | an estimated US$ 30250 million |

| Forecasted market size in 2030 | US$ 37180 million |

| CAGR | 3.5% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hitachi Metals, Grede Foundry, Wescast Industries, Draxton, Tianjin New Wei San Industrial, Aludyne, Metal Technologies, Inc., MAT Foundry, Castings PLC, Weichai Power (Weifang) Casting, FAW Foundry Co., Ltd., Georg Fischer, Huaxiang Group, ACO Eurobar, INTAT Precision, Meide Group, Neenah Foundry, Silbitz Group, Goldens’Foundry, Rochester Metal Products, Kutno, Denizciler, Aarrowcast, Inc., Willman Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |