What is Global Densified Silica Fumes Market?

The Global Densified Silica Fumes Market refers to the worldwide trade and utilization of densified silica fumes, which are ultra-fine particles derived from the production of silicon and ferrosilicon alloys. These particles are known for their high surface area and pozzolanic properties, making them valuable in various industrial applications. Densified silica fumes are primarily used to enhance the strength and durability of concrete, improve the performance of refractory materials, and serve as additives in other products. The market for these materials is driven by the growing demand in construction, mining, marine, glass, ceramics, and rubber industries. The global market is characterized by its diverse applications and the increasing need for high-performance materials in various sectors.

0.85, 0.92, 0.94, 0.96, Others in the Global Densified Silica Fumes Market:

In the Global Densified Silica Fumes Market, different grades of densified silica fumes are available, including 0.85, 0.92, 0.94, 0.96, and others. These grades refer to the specific density of the silica fumes, which affects their performance and suitability for different applications. The 0.85 grade is typically used in applications where a lower density is required, such as in lightweight concrete and certain refractory materials. This grade helps in reducing the overall weight of the final product while still providing the necessary strength and durability. The 0.92 grade is slightly denser and is often used in standard concrete mixtures to enhance their compressive strength and resistance to chemical attacks. This grade is also used in the production of high-performance concrete for infrastructure projects that require superior durability. The 0.94 grade is known for its high density and is used in applications where maximum strength and durability are essential, such as in marine structures and heavy-duty industrial flooring. This grade provides excellent resistance to abrasion and chemical corrosion, making it ideal for harsh environments. The 0.96 grade is the densest among the commonly used grades and is used in specialized applications that require the highest level of performance. This grade is often used in the production of ultra-high-performance concrete (UHPC) and advanced refractory materials that need to withstand extreme temperatures and mechanical stresses. Other grades of densified silica fumes are also available, catering to specific requirements in niche applications. These grades are formulated to provide unique properties, such as enhanced workability, improved thermal stability, or increased resistance to specific chemicals. The choice of grade depends on the specific needs of the application and the desired performance characteristics of the final product. The availability of different grades allows manufacturers and end-users to select the most suitable densified silica fume for their specific requirements, ensuring optimal performance and cost-effectiveness.

Mining & Metal Processing, Marine Industry, Construction Industry, Glass & Ceramics Industry, Rubber Industry, Others in the Global Densified Silica Fumes Market:

The Global Densified Silica Fumes Market finds extensive usage across various industries, including mining and metal processing, marine, construction, glass and ceramics, rubber, and others. In the mining and metal processing industry, densified silica fumes are used to enhance the properties of concrete used in underground structures and mining operations. The addition of silica fumes improves the strength and durability of the concrete, making it more resistant to the harsh conditions encountered in mining environments. In the marine industry, densified silica fumes are used in the construction of marine structures such as piers, docks, and offshore platforms. The high density and pozzolanic properties of silica fumes help in producing concrete that can withstand the corrosive effects of seawater and the mechanical stresses imposed by waves and tides. In the construction industry, densified silica fumes are widely used to produce high-performance concrete for various applications, including bridges, tunnels, high-rise buildings, and industrial floors. The addition of silica fumes enhances the compressive strength, durability, and resistance to chemical attacks of the concrete, making it suitable for demanding construction projects. In the glass and ceramics industry, densified silica fumes are used as additives to improve the properties of glass and ceramic products. The fine particles of silica fumes help in reducing the porosity and increasing the strength of the final products, making them more durable and resistant to thermal and mechanical stresses. In the rubber industry, densified silica fumes are used as reinforcing fillers to enhance the mechanical properties of rubber products. The addition of silica fumes improves the tensile strength, abrasion resistance, and overall durability of rubber compounds, making them suitable for various applications, including tires, seals, and gaskets. Other industries also benefit from the use of densified silica fumes, including the production of paints, coatings, adhesives, and sealants. The unique properties of silica fumes, such as high surface area and pozzolanic activity, make them valuable additives in these products, improving their performance and durability. The versatility and effectiveness of densified silica fumes make them an essential material in various industrial applications, driving the growth of the global market.

Global Densified Silica Fumes Market Outlook:

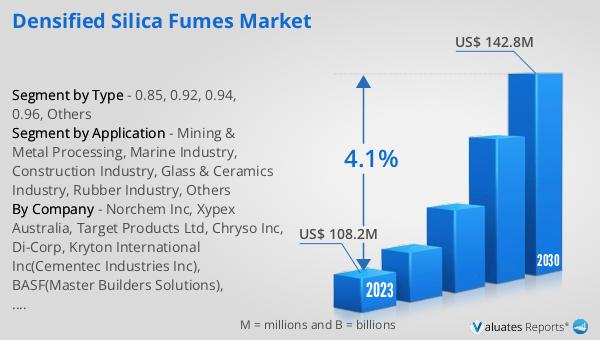

In the production of concrete, the use of densified silica fumes significantly enhances the uniformity of mixing and improves the overall performance of the concrete. This is because the fine particles of silica fumes fill the voids between cement particles, leading to a denser and more cohesive mixture. Additionally, densified silica fumes are also utilized in the manufacturing of refractory materials and other products that require high thermal stability and mechanical strength. The global market for densified silica fumes was valued at US$ 108.2 million in 2023 and is expected to reach US$ 142.8 million by 2030, growing at a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030.

| Report Metric | Details |

| Report Name | Densified Silica Fumes Market |

| Accounted market size in 2023 | US$ 108.2 million |

| Forecasted market size in 2030 | US$ 142.8 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Norchem Inc, Xypex Australia, Target Products Ltd, Chryso Inc, Di-Corp, Kryton International Inc(Cementec Industries Inc), BASF(Master Builders Solutions), RussTech, Sika Corporation, Scancem Materials(Singapore)Pte Ltd, Elkem, Diversified Minerals,Inc., Wuhan Newreach Microsilica Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |