What is Global Clad Pipes Market?

The Global Clad Pipes Market refers to the industry that produces and supplies clad pipes, which are composite pipes made by bonding different metals together. These pipes combine the strength and durability of carbon steel with the corrosion resistance of materials like stainless steel, nickel-based alloys, or titanium. Clad pipes are essential in industries where both mechanical strength and corrosion resistance are critical, such as oil and gas, chemical processing, and water treatment. The market for these pipes is driven by the need for reliable and long-lasting piping solutions that can withstand harsh environments and aggressive chemicals. As industries continue to expand and modernize, the demand for clad pipes is expected to grow, making this market a vital component of global industrial infrastructure.

by Process, Roll Bonding Process, Mechanically, Explosive Bonding Process, Weld Overlay Process, by Material, Stainless Steels, Nickel-based alloys, Titanium, Others, bt Diameter in the Global Clad Pipes Market:

The Global Clad Pipes Market can be segmented based on various processes and materials used in their production. One of the primary processes is Roll Bonding, where metals are bonded together by rolling them under high pressure. This method is widely used due to its efficiency and ability to produce large quantities of clad pipes. Another process is Mechanical Cladding, which involves mechanically bonding the metals together, often using techniques like extrusion or drawing. Explosive Bonding is another method, where an explosive charge is used to bond the metals together, creating a strong and durable bond. This process is particularly useful for bonding dissimilar metals that are difficult to join using other methods. Weld Overlay is another technique, where a layer of corrosion-resistant material is welded onto the surface of a base metal, providing enhanced protection against corrosion and wear. In terms of materials, clad pipes can be made from various metals, including Stainless Steels, which offer excellent corrosion resistance and mechanical properties. Nickel-based alloys are also commonly used, providing superior resistance to high temperatures and aggressive chemicals. Titanium is another material used in clad pipes, known for its exceptional strength and corrosion resistance, making it ideal for demanding applications. Other materials used in clad pipes include various alloys and metals that offer specific properties required for different applications. The diameter of clad pipes can vary based on the requirements of the application, with larger diameters often used in industries like oil and gas, where large volumes of fluids need to be transported. Smaller diameters are typically used in applications where space is limited or where precise control of fluid flow is required. Overall, the Global Clad Pipes Market is characterized by a diverse range of processes, materials, and diameters, each tailored to meet the specific needs of different industries and applications.

Oil & Gas, Chemical Industry, Water Treatment, Others in the Global Clad Pipes Market:

The usage of clad pipes in the Global Clad Pipes Market spans several critical industries, each with unique requirements and challenges. In the Oil & Gas industry, clad pipes are extensively used for transporting crude oil, natural gas, and other hydrocarbons. The harsh environments and corrosive substances encountered in this industry necessitate the use of pipes that can withstand high pressures and resist corrosion. Clad pipes provide the necessary durability and reliability, ensuring the safe and efficient transport of these valuable resources. In the Chemical Industry, clad pipes are used to handle aggressive chemicals and high-temperature processes. The corrosion resistance of materials like stainless steel and nickel-based alloys makes them ideal for use in chemical processing plants, where they can prevent contamination and extend the lifespan of the piping systems. Water Treatment is another area where clad pipes play a crucial role. The treatment of water often involves exposure to corrosive substances and varying pH levels, which can quickly degrade standard piping materials. Clad pipes offer enhanced resistance to these conditions, ensuring the longevity and effectiveness of water treatment systems. Other industries that benefit from the use of clad pipes include power generation, where they are used in high-temperature and high-pressure environments, and the marine industry, where their resistance to seawater corrosion is invaluable. Overall, the versatility and durability of clad pipes make them an essential component in a wide range of industrial applications, providing reliable performance and reducing maintenance costs.

Global Clad Pipes Market Outlook:

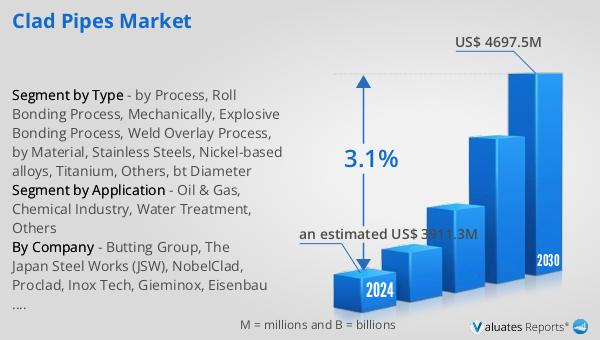

The global Clad Pipes market is anticipated to grow significantly, with projections indicating it will reach US$ 4697.5 million by 2030, up from an estimated US$ 3911.3 million in 2024. This growth represents a compound annual growth rate (CAGR) of 3.1% during the period from 2024 to 2030. In 2019, the top five manufacturers in the market accounted for 40.37% of the total market share, highlighting the competitive nature of the industry. The increasing demand for durable and corrosion-resistant piping solutions across various industries is a key driver of this market growth. As industries such as oil and gas, chemical processing, and water treatment continue to expand and modernize, the need for reliable and long-lasting clad pipes is expected to rise. This market outlook underscores the importance of innovation and quality in maintaining a competitive edge in the Global Clad Pipes Market.

| Report Metric | Details |

| Report Name | Clad Pipes Market |

| Accounted market size in 2024 | an estimated US$ 3911.3 million |

| Forecasted market size in 2030 | US$ 4697.5 million |

| CAGR | 3.1% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Butting Group, The Japan Steel Works (JSW), NobelClad, Proclad, Inox Tech, Gieminox, Eisenbau Kramer (EBK), Cladtek Holdings, EEW Group, Canadoil Group, Xinxing Ductile, Jiangsu New Sunshine, Zhejiang Jiuli Group, Xian Sunward Aeromat, Jiangsu Shunlong, Jiangsu Zhongxin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |