What is Global Carbon Carbon Composites Market?

The Global Carbon Carbon Composites Market refers to the worldwide industry focused on the production and distribution of carbon-carbon composites. These composites are materials made from carbon fibers embedded in a carbon matrix, which are known for their exceptional strength, lightweight properties, and high thermal resistance. They are used in a variety of high-performance applications, including aerospace, automotive, and industrial sectors. The market encompasses various processes and technologies for manufacturing these composites, as well as the supply chain and distribution networks that deliver them to end-users. The demand for carbon-carbon composites is driven by their superior performance characteristics, which make them ideal for use in extreme environments where traditional materials would fail. The market is also influenced by advancements in manufacturing techniques and the development of new applications for these versatile materials.

Chemical Vapor Deposition, Liquid Impregnation Process in the Global Carbon Carbon Composites Market:

Chemical Vapor Deposition (CVD) and Liquid Impregnation Process are two primary methods used in the production of carbon-carbon composites within the Global Carbon Carbon Composites Market. CVD involves the deposition of a carbon matrix onto carbon fibers through a chemical reaction of gaseous precursors. This process typically occurs in a high-temperature furnace where gases like methane or acetylene are introduced. The gases decompose upon contact with the heated carbon fibers, resulting in the formation of a solid carbon matrix that binds the fibers together. CVD is known for producing composites with high purity and excellent mechanical properties, making it suitable for applications requiring high strength and thermal stability. On the other hand, the Liquid Impregnation Process involves the infiltration of a liquid carbon precursor, such as a resin or pitch, into a preform made of carbon fibers. The preform is then subjected to a series of heat treatments to convert the liquid precursor into a solid carbon matrix. This process can be repeated multiple times to achieve the desired density and mechanical properties. Liquid Impregnation is often used for producing large and complex-shaped components, as it allows for better control over the final composite structure. Both CVD and Liquid Impregnation have their unique advantages and are chosen based on the specific requirements of the application. For instance, CVD is preferred for high-performance aerospace components due to its ability to produce composites with superior thermal and mechanical properties. In contrast, Liquid Impregnation is favored for industrial applications where large and intricate shapes are needed. The choice of process also depends on factors such as cost, production volume, and the desired properties of the final composite. Overall, these manufacturing techniques play a crucial role in the Global Carbon Carbon Composites Market, enabling the production of high-quality materials that meet the demanding requirements of various industries.

CZ and DSS Furnaces, C/C Grid Shelving Systems, Glass Handling Industry, Aerospace Items, Basic C/C Plate Stock Producing, Others in the Global Carbon Carbon Composites Market:

The Global Carbon Carbon Composites Market finds extensive usage across several key areas, including CZ and DSS furnaces, C/C grid shelving systems, the glass handling industry, aerospace items, basic C/C plate stock producing, and others. In CZ (Czochralski) and DSS (Directional Solidification System) furnaces, carbon-carbon composites are used for their high thermal stability and resistance to thermal shock. These properties are essential for the production of high-purity silicon crystals used in the semiconductor industry. The composites' ability to withstand extreme temperatures without deforming or degrading makes them ideal for furnace components such as crucibles and heaters. In C/C grid shelving systems, carbon-carbon composites provide a lightweight yet strong solution for high-temperature processing environments. These shelving systems are used in various industrial applications, including heat treatment and sintering processes, where they offer excellent thermal conductivity and resistance to oxidation. The glass handling industry also benefits from the use of carbon-carbon composites, particularly in the production and handling of high-temperature glass products. The composites' non-reactive nature and high thermal resistance make them suitable for components such as rollers and molds, ensuring the integrity and quality of the glass products. In the aerospace sector, carbon-carbon composites are used in a wide range of applications, including aircraft brakes, rocket nozzles, and thermal protection systems. Their lightweight and high-strength properties contribute to improved fuel efficiency and performance, while their ability to withstand extreme temperatures ensures the safety and reliability of aerospace components. Basic C/C plate stock producing involves the manufacture of carbon-carbon composite plates, which serve as raw materials for various industrial applications. These plates are used in the production of components that require high thermal and mechanical performance, such as heat exchangers and structural parts. Other applications of carbon-carbon composites include their use in medical devices, automotive components, and energy storage systems. The versatility and superior performance characteristics of these composites make them suitable for a wide range of demanding applications, driving their adoption across multiple industries.

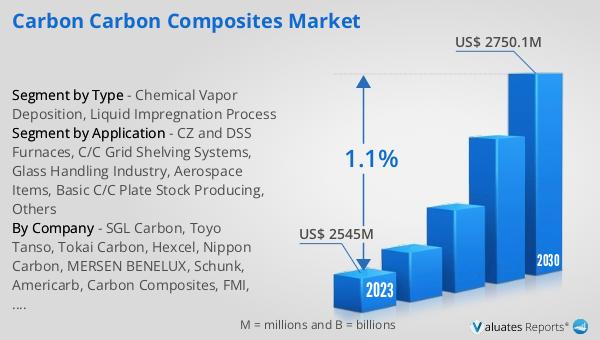

Global Carbon Carbon Composites Market Outlook:

The global Carbon Carbon Composites market is anticipated to grow from an estimated US$ 2575.4 million in 2024 to reach US$ 2750.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 1.1% during the period from 2024 to 2030. This growth projection underscores the increasing demand for carbon-carbon composites across various industries due to their exceptional properties, such as high strength, lightweight, and thermal resistance. The market's expansion is driven by advancements in manufacturing technologies and the development of new applications that leverage the unique characteristics of these composites. As industries continue to seek materials that can perform under extreme conditions, the demand for carbon-carbon composites is expected to rise, contributing to the market's steady growth. The projected market size indicates a positive outlook for the industry, with opportunities for innovation and increased adoption of carbon-carbon composites in diverse applications.

| Report Metric | Details |

| Report Name | Carbon Carbon Composites Market |

| Accounted market size in 2024 | an estimated US$ 2575.4 million |

| Forecasted market size in 2030 | US$ 2750.1 million |

| CAGR | 1.1% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | SGL Carbon, Toyo Tanso, Tokai Carbon, Hexcel, Nippon Carbon, MERSEN BENELUX, Schunk, Americarb, Carbon Composites, FMI, Luhang Carbon, Graphtek, KBC, Boyun, Chaoma, Jiuhua Carbon, Chemshine, Bay Composites, Haoshi Carbon, Jining Carbon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |