What is Global Brazed Aluminum Heat Exchangers Market?

The global Brazed Aluminum Heat Exchangers (BAHE) market is a specialized segment within the broader heat exchanger industry. These heat exchangers are designed to transfer heat between two or more fluids without mixing them. They are made from aluminum, which is lightweight, highly conductive, and resistant to corrosion. The brazing process involves joining aluminum components using a filler metal, creating a strong, leak-proof bond. BAHEs are widely used in industries that require efficient heat transfer, such as petrochemical processing, natural gas processing, and industrial gas production. Their compact size, high thermal efficiency, and ability to handle high pressures and temperatures make them ideal for these applications. The market for BAHEs is driven by the increasing demand for energy-efficient and environmentally friendly technologies. As industries continue to seek ways to reduce energy consumption and emissions, the adoption of BAHEs is expected to grow. Additionally, advancements in manufacturing techniques and materials are likely to enhance the performance and durability of these heat exchangers, further boosting their market potential.

Plain, Serrated, Perforated, Others in the Global Brazed Aluminum Heat Exchangers Market:

In the Global Brazed Aluminum Heat Exchangers Market, products are categorized based on their fin types, which include plain, serrated, perforated, and others. Plain fins are the most basic type, featuring a smooth surface that facilitates straightforward heat transfer. These fins are typically used in applications where the heat transfer requirements are moderate, and the fluid flow is relatively clean. Their simplicity makes them cost-effective and easy to manufacture, contributing to their widespread use. Serrated fins, on the other hand, have a saw-tooth pattern that increases the surface area for heat transfer. This design enhances the turbulence of the fluid flow, improving the overall heat transfer efficiency. Serrated fins are particularly useful in applications where higher heat transfer rates are needed, and the fluids involved may have higher viscosities or contain particulates. Perforated fins feature small holes or slots that further increase the surface area and promote better fluid mixing. This design is beneficial in applications where maximizing heat transfer efficiency is critical, and the fluids may have varying thermal properties. The perforations help in breaking up boundary layers, thereby enhancing the heat transfer process. Other types of fins in the market include louvered and wavy fins, each designed to meet specific heat transfer requirements. Louvered fins have small, angled slits that create additional turbulence and improve heat transfer, while wavy fins have a corrugated pattern that increases the surface area and fluid mixing. These specialized fins are used in niche applications where standard fin designs may not provide the desired performance. The choice of fin type depends on various factors, including the nature of the fluids, the required heat transfer rate, and the operating conditions. Manufacturers in the BAHE market continuously innovate to develop fin designs that offer higher efficiency, durability, and cost-effectiveness. The ongoing research and development efforts aim to address the evolving needs of industries and enhance the overall performance of brazed aluminum heat exchangers.

Industrial Gas Production, Petrochemical Processing, Natural Gas Processing, Liquid Natural Gas, Others in the Global Brazed Aluminum Heat Exchangers Market:

The usage of Global Brazed Aluminum Heat Exchangers (BAHE) spans several critical areas, including industrial gas production, petrochemical processing, natural gas processing, liquid natural gas (LNG), and others. In industrial gas production, BAHEs are essential for processes that involve the separation and purification of gases such as oxygen, nitrogen, and argon. These heat exchangers help in maintaining the required temperatures and pressures, ensuring efficient and cost-effective gas production. Their ability to handle high pressures and temperatures makes them ideal for these demanding applications. In petrochemical processing, BAHEs play a crucial role in various stages of production, including the cooling and heating of chemical compounds. The high thermal efficiency and compact size of these heat exchangers make them suitable for use in refineries and chemical plants, where space is often limited, and efficient heat transfer is critical. They help in optimizing the energy consumption and improving the overall process efficiency. Natural gas processing involves the removal of impurities and the separation of valuable components such as methane, ethane, and propane. BAHEs are used in various stages of this process, including gas cooling, condensation, and liquefaction. Their ability to provide efficient heat transfer and withstand harsh operating conditions makes them indispensable in natural gas processing plants. In the LNG sector, BAHEs are used in the liquefaction process, where natural gas is cooled to extremely low temperatures to convert it into a liquid state. This process requires highly efficient heat exchangers that can handle the low temperatures and high pressures involved. BAHEs are well-suited for this application due to their high thermal conductivity and durability. Other applications of BAHEs include air separation units, refrigeration systems, and power generation. In air separation units, these heat exchangers are used to cool and separate air into its primary components, such as oxygen and nitrogen. In refrigeration systems, BAHEs help in maintaining the desired temperatures by efficiently transferring heat between the refrigerant and the surrounding environment. In power generation, they are used in various stages of the process, including cooling and heating of fluids, to improve the overall efficiency of the power plants. The versatility and efficiency of BAHEs make them a preferred choice in these diverse applications.

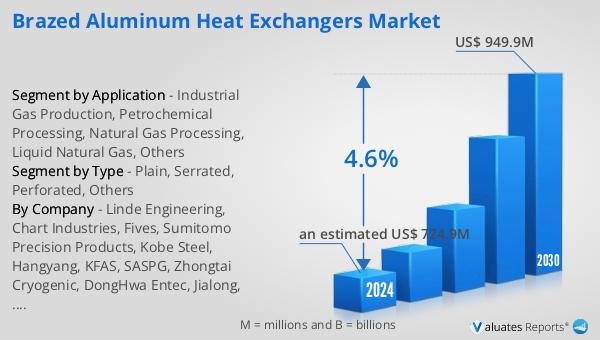

Global Brazed Aluminum Heat Exchangers Market Outlook:

The global Brazed Aluminum Heat Exchangers market is anticipated to grow from an estimated US$ 724.9 million in 2024 to US$ 949.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.6% during the forecast period. The market is dominated by the top five manufacturers, which include Linde Engineering, Chart Industries, Fives, Sumitomo Precision Products, and Kobe Steel, collectively accounting for about 50% of the market share. Among these, Linde Engineering leads with approximately 12% market share. Geographically, Europe holds the largest market share, exceeding 25%, followed by China and North America, with shares of around 24% and 20%, respectively. In terms of product types, plain fins occupy the largest portion of the market, accounting for over 35% of the total market share. This dominance is attributed to their cost-effectiveness and ease of manufacturing, making them a popular choice across various applications. The market's growth is driven by the increasing demand for energy-efficient and environmentally friendly technologies, as well as advancements in manufacturing techniques and materials that enhance the performance and durability of brazed aluminum heat exchangers.

| Report Metric | Details |

| Report Name | Brazed Aluminum Heat Exchangers Market |

| Accounted market size in 2024 | an estimated US$ 724.9 million |

| Forecasted market size in 2030 | US$ 949.9 million |

| CAGR | 4.6% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Linde Engineering, Chart Industries, Fives, Sumitomo Precision Products, Kobe Steel, Hangyang, KFAS, SASPG, Zhongtai Cryogenic, DongHwa Entec, Jialong, Guanyun, Fang Sheng |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |