What is Global 3D Automated Optical Inspection (AOI) System Market?

The Global 3D Automated Optical Inspection (AOI) System Market is a rapidly evolving sector that focuses on the use of advanced technology to inspect electronic components and assemblies. These systems utilize 3D imaging to detect defects and ensure quality control in manufacturing processes. Unlike traditional 2D AOI systems, 3D AOI systems provide a more comprehensive analysis by capturing height information, which is crucial for identifying issues such as solder joint defects, component placement errors, and other surface irregularities. The market for these systems is driven by the increasing complexity of electronic devices and the need for higher precision in manufacturing. Industries such as consumer electronics, automotive, medical devices, aerospace, and defense are major adopters of 3D AOI systems due to their stringent quality requirements. As technology continues to advance, the demand for more sophisticated inspection solutions is expected to grow, making the Global 3D AOI System Market a key area of interest for manufacturers and investors alike.

Inline AOI, Offline AOI in the Global 3D Automated Optical Inspection (AOI) System Market:

Inline AOI and Offline AOI are two primary types of systems used in the Global 3D Automated Optical Inspection (AOI) System Market. Inline AOI systems are integrated directly into the production line, allowing for real-time inspection and immediate feedback. This integration helps in identifying defects as they occur, thereby reducing the chances of defective products reaching the end of the production line. Inline AOI systems are particularly beneficial in high-volume manufacturing environments where speed and efficiency are critical. They help in maintaining a continuous flow of production while ensuring that quality standards are met. On the other hand, Offline AOI systems are standalone units that are not directly connected to the production line. These systems are used for batch inspection and are ideal for low to medium-volume production environments. Offline AOI systems offer flexibility as they can be used to inspect different types of products without disrupting the production process. They are also useful for detailed analysis and rework, as they allow operators to focus on specific areas of concern. Both Inline and Offline AOI systems have their unique advantages and are chosen based on the specific needs of the manufacturing process. Inline AOI systems are preferred for their speed and efficiency, while Offline AOI systems are valued for their flexibility and detailed inspection capabilities. The choice between Inline and Offline AOI systems depends on various factors such as production volume, complexity of the products, and the level of inspection required. As the demand for high-quality electronic components continues to rise, the adoption of both Inline and Offline AOI systems is expected to increase, driving the growth of the Global 3D AOI System Market.

Consumer Electronics, Automotive, Medical Devices, Aerospace & Defense, Industrial Electronics, Energy & Power, Others in the Global 3D Automated Optical Inspection (AOI) System Market:

The usage of Global 3D Automated Optical Inspection (AOI) Systems spans across various industries, each with its unique requirements and challenges. In the consumer electronics sector, 3D AOI systems are essential for ensuring the quality and reliability of products such as smartphones, tablets, and laptops. These devices have intricate designs and small components that require precise inspection to avoid defects. In the automotive industry, 3D AOI systems are used to inspect electronic control units (ECUs), sensors, and other critical components that ensure the safety and performance of vehicles. The stringent quality standards in the automotive sector make 3D AOI systems indispensable for detecting even the smallest defects. In the medical devices industry, 3D AOI systems play a crucial role in inspecting components such as printed circuit boards (PCBs) used in medical equipment. The high stakes involved in medical applications necessitate the use of advanced inspection systems to ensure the reliability and safety of medical devices. In the aerospace and defense sector, 3D AOI systems are used to inspect complex electronic assemblies that are critical for the performance and safety of aircraft and defense systems. The high precision and reliability required in this sector make 3D AOI systems a vital part of the manufacturing process. In the industrial electronics sector, 3D AOI systems are used to inspect components used in industrial automation, robotics, and other applications. The need for high reliability and performance in industrial applications drives the adoption of 3D AOI systems. In the energy and power sector, 3D AOI systems are used to inspect electronic components used in power generation, distribution, and storage systems. The reliability and efficiency of these systems are critical for ensuring a stable power supply. Other industries such as telecommunications, consumer appliances, and lighting also benefit from the use of 3D AOI systems for quality control and defect detection. The versatility and advanced capabilities of 3D AOI systems make them an essential tool for ensuring the quality and reliability of electronic components across various industries.

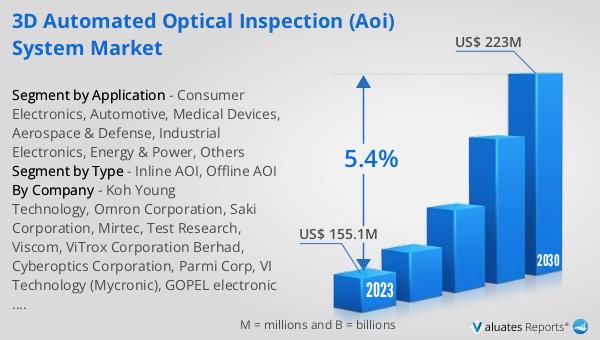

Global 3D Automated Optical Inspection (AOI) System Market Outlook:

The global 3D Automated Optical Inspection (AOI) System market was valued at US$ 155.1 million in 2023 and is anticipated to reach US$ 223 million by 2030, witnessing a CAGR of 5.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality electronic components and the need for advanced inspection solutions in various industries. The adoption of 3D AOI systems is expected to rise as manufacturers seek to improve their production processes and ensure the reliability of their products. The market's expansion is also supported by technological advancements that enhance the capabilities of 3D AOI systems, making them more efficient and accurate. As industries continue to evolve and the complexity of electronic devices increases, the demand for sophisticated inspection systems is likely to grow, further driving the market's growth. The Global 3D AOI System Market is poised for significant growth, offering numerous opportunities for manufacturers, investors, and other stakeholders in the industry.

| Report Metric | Details |

| Report Name | 3D Automated Optical Inspection (AOI) System Market |

| Accounted market size in 2023 | US$ 155.1 million |

| Forecasted market size in 2030 | US$ 223 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koh Young Technology, Omron Corporation, Saki Corporation, Mirtec, Test Research, Viscom, ViTrox Corporation Berhad, Cyberoptics Corporation, Parmi Corp, VI Technology (Mycronic), GOPEL electronic GmbH, Machine Vision Products (MVP), Mek Marantz Electronics, Pemtron Corp., Nordson YESTECH, JUTZE Intelligence Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |