What is Global Robotic Waste Sorting Market?

The Global Robotic Waste Sorting Market is a rapidly evolving sector that leverages advanced robotics and artificial intelligence to sort and manage waste more efficiently. This market encompasses a wide range of technologies designed to automate the sorting process, which traditionally relies on manual labor. By using robotic systems equipped with sensors, cameras, and machine learning algorithms, waste can be sorted into various categories such as plastics, metals, paper, and organic materials with high precision. This not only enhances the efficiency of recycling processes but also significantly reduces the contamination rates in recyclable materials. The adoption of robotic waste sorting systems is driven by the increasing need for sustainable waste management solutions, stringent government regulations, and the rising awareness about environmental conservation. These systems are being implemented in various sectors, including municipal waste management, industrial waste processing, and commercial recycling facilities, making them a crucial component in the global effort to manage waste more sustainably.

Light Robotic Waste Sorting, Heavy Robotic Waste Sorting in the Global Robotic Waste Sorting Market:

Light robotic waste sorting and heavy robotic waste sorting are two primary categories within the Global Robotic Waste Sorting Market, each serving distinct purposes based on the type and volume of waste being processed. Light robotic waste sorting systems are typically used for handling smaller, lighter materials such as plastics, paper, and lightweight metals. These systems are designed to operate at high speeds, efficiently sorting through large volumes of waste with minimal human intervention. They are equipped with advanced sensors and machine learning algorithms that enable them to identify and separate different types of materials with high accuracy. Light robotic waste sorting systems are commonly used in municipal recycling facilities, where the focus is on processing household waste and other lightweight materials. On the other hand, heavy robotic waste sorting systems are designed to handle bulkier, heavier materials such as construction debris, industrial waste, and large metal objects. These systems are built to withstand the rigors of sorting through dense and often hazardous materials, making them ideal for use in construction and demolition sites, industrial waste processing plants, and other heavy-duty applications. Heavy robotic waste sorting systems are equipped with robust mechanical arms, powerful sensors, and advanced software that enable them to identify and sort heavy materials with precision. They play a crucial role in reducing the amount of waste that ends up in landfills by efficiently separating recyclable materials from non-recyclable ones. Both light and heavy robotic waste sorting systems contribute significantly to the efficiency and effectiveness of waste management processes. By automating the sorting process, these systems reduce the reliance on manual labor, lower operational costs, and improve the overall quality of recycled materials. Additionally, they help in minimizing the environmental impact of waste by ensuring that recyclable materials are properly sorted and processed. As the demand for sustainable waste management solutions continues to grow, the adoption of both light and heavy robotic waste sorting systems is expected to increase, driving further advancements in the Global Robotic Waste Sorting Market.

Electronics Recycling, Materials Recovery Facility, PET Recycling, Mixed Waste, Construction and Demolition, Others in the Global Robotic Waste Sorting Market:

The usage of Global Robotic Waste Sorting Market spans across various sectors, each benefiting from the efficiency and precision offered by robotic systems. In electronics recycling, robotic waste sorting systems are used to separate valuable materials such as metals, plastics, and glass from electronic waste. These systems are equipped with advanced sensors and machine learning algorithms that can identify and sort different components with high accuracy, ensuring that valuable materials are recovered and hazardous substances are safely disposed of. This not only enhances the efficiency of the recycling process but also reduces the environmental impact of electronic waste. In materials recovery facilities (MRFs), robotic waste sorting systems play a crucial role in automating the sorting process. These facilities handle a wide range of materials, including plastics, metals, paper, and glass, which need to be sorted and processed for recycling. Robotic systems equipped with advanced sensors and machine learning algorithms can quickly and accurately identify and separate different types of materials, improving the efficiency and effectiveness of the recycling process. This helps in reducing contamination rates and ensuring that high-quality recycled materials are produced. PET recycling is another area where robotic waste sorting systems are extensively used. PET (polyethylene terephthalate) is a type of plastic commonly used in beverage bottles and other packaging materials. Robotic systems can efficiently sort PET from other types of plastics and contaminants, ensuring that high-quality PET is recovered for recycling. This not only helps in reducing the amount of plastic waste that ends up in landfills but also supports the production of recycled PET, which can be used to manufacture new products. In mixed waste processing, robotic waste sorting systems are used to handle a diverse range of materials that are often mixed together. These systems are equipped with advanced sensors and machine learning algorithms that can identify and sort different types of materials with high accuracy, ensuring that recyclable materials are recovered and non-recyclable materials are properly disposed of. This helps in improving the efficiency of waste management processes and reducing the environmental impact of mixed waste. Construction and demolition (C&D) waste is another area where robotic waste sorting systems are extensively used. C&D waste includes materials such as concrete, wood, metals, and plastics, which need to be sorted and processed for recycling. Robotic systems equipped with robust mechanical arms and advanced sensors can efficiently sort through dense and often hazardous materials, ensuring that recyclable materials are recovered and non-recyclable materials are properly disposed of. This helps in reducing the amount of C&D waste that ends up in landfills and supports the production of recycled materials for use in new construction projects. Other areas where robotic waste sorting systems are used include industrial waste processing, commercial recycling facilities, and municipal waste management. In industrial waste processing, robotic systems are used to handle a wide range of materials, including metals, plastics, and hazardous substances, ensuring that valuable materials are recovered and hazardous substances are safely disposed of. In commercial recycling facilities, robotic systems are used to automate the sorting process, improving the efficiency and effectiveness of recycling operations. In municipal waste management, robotic systems are used to handle household waste and other lightweight materials, ensuring that recyclable materials are properly sorted and processed. Overall, the usage of Global Robotic Waste Sorting Market in various sectors highlights the importance of advanced robotic systems in improving the efficiency and effectiveness of waste management processes. By automating the sorting process, these systems help in reducing the reliance on manual labor, lowering operational costs, and improving the overall quality of recycled materials. Additionally, they help in minimizing the environmental impact of waste by ensuring that recyclable materials are properly sorted and processed, supporting the global effort to manage waste more sustainably.

Global Robotic Waste Sorting Market Outlook:

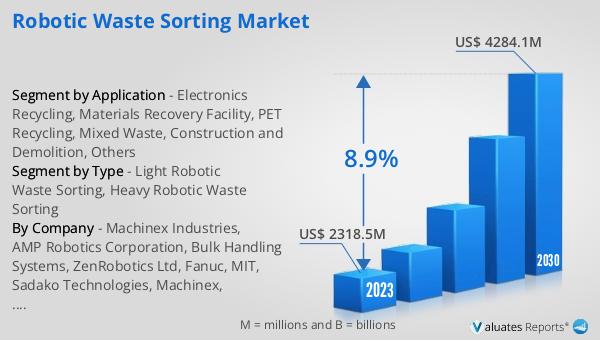

The global Robotic Waste Sorting market, valued at US$ 2318.5 million in 2023, is projected to grow significantly, reaching an estimated US$ 4284.1 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.9% during the forecast period from 2024 to 2030. This market outlook underscores the increasing adoption of robotic waste sorting systems across various sectors, driven by the need for more efficient and sustainable waste management solutions. The advancements in robotics and artificial intelligence have enabled the development of sophisticated sorting systems that can handle a wide range of materials with high precision and speed. These systems are being increasingly implemented in municipal waste management, industrial waste processing, and commercial recycling facilities, among others, to enhance the efficiency of recycling processes and reduce the environmental impact of waste. The projected growth of the global Robotic Waste Sorting market reflects the rising awareness about environmental conservation and the stringent government regulations aimed at promoting sustainable waste management practices. As more industries and municipalities adopt robotic waste sorting systems, the market is expected to witness significant advancements and innovations, further driving its growth in the coming years.

| Report Metric | Details |

| Report Name | Robotic Waste Sorting Market |

| Accounted market size in 2023 | US$ 2318.5 million |

| Forecasted market size in 2030 | US$ 4284.1 million |

| CAGR | 8.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Machinex Industries, AMP Robotics Corporation, Bulk Handling Systems, ZenRobotics Ltd, Fanuc, MIT, Sadako Technologies, Machinex, Recycleye, Bollegraa, Greyparrot, Smarter Sorting, Pellenc, Waste Robotic, Everest Labs, LIXO, Gongye Technology, Suzhou JONO Environment Technology, Enerpat, ONKY Robotic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |