What is Global Coater and Developer Market?

The Global Coater and Developer Market is a specialized segment within the semiconductor manufacturing industry. Coaters and developers are essential tools used in the photolithography process, which is a critical step in the production of semiconductor devices. These machines apply photoresist coatings to silicon wafers and then develop the patterns created by exposure to light. The market for these tools is driven by the increasing demand for advanced semiconductor devices, which are used in a wide range of applications, from consumer electronics to automotive systems. As technology advances, the need for more precise and efficient coating and developing processes becomes more critical, leading to continuous innovation and development in this market. The global coater and developer market is characterized by a high level of competition, with several key players striving to offer the most advanced and reliable equipment. This market is also influenced by trends in the semiconductor industry, such as the move towards smaller and more complex chip designs, which require more sophisticated photolithography processes. Overall, the global coater and developer market plays a crucial role in the semiconductor manufacturing ecosystem, enabling the production of the advanced electronic devices that power our modern world.

6 Inches, 8 Inches, 12 Inches, Others in the Global Coater and Developer Market:

In the Global Coater and Developer Market, the sizes of the equipment, such as 6 inches, 8 inches, 12 inches, and others, play a significant role in determining their application and efficiency. The 6-inch coater and developer machines are typically used for smaller-scale production and research and development purposes. These machines are ideal for producing small batches of semiconductor devices, making them suitable for specialized applications and prototyping. The 8-inch machines, on the other hand, are more commonly used in medium-scale production environments. They offer a balance between production capacity and cost, making them a popular choice for many semiconductor manufacturers. The 12-inch coater and developer machines represent the latest and most advanced technology in the market. These machines are designed for high-volume production and are capable of handling the largest silicon wafers currently used in the industry. The larger wafer size allows for more chips to be produced per wafer, increasing efficiency and reducing costs. In addition to these standard sizes, there are also other specialized coater and developer machines available in the market. These machines are designed for specific applications and can handle a variety of wafer sizes and materials. The choice of equipment size depends on several factors, including the scale of production, the type of semiconductor devices being produced, and the specific requirements of the manufacturing process. As the semiconductor industry continues to evolve, the demand for more advanced and versatile coater and developer machines is expected to grow. Manufacturers are constantly innovating to develop new equipment that can meet the changing needs of the industry. This includes the development of machines that can handle larger wafer sizes, as well as those that can provide more precise and uniform coatings. The competition in the market is intense, with several key players striving to offer the most advanced and reliable equipment. This has led to continuous improvements in the performance and capabilities of coater and developer machines. Overall, the different sizes of coater and developer machines in the global market cater to a wide range of applications and production needs, making them an essential part of the semiconductor manufacturing process.

Chip Manufacturing, Integrated Circuit Manufacturing, Others in the Global Coater and Developer Market:

The Global Coater and Developer Market finds extensive usage in various areas, including chip manufacturing, integrated circuit manufacturing, and other specialized applications. In chip manufacturing, coaters and developers are crucial for applying photoresist layers to silicon wafers and developing the intricate patterns required for creating semiconductor devices. This process is essential for producing the tiny transistors and other components that make up modern microchips. The precision and uniformity of the coating and developing process directly impact the performance and reliability of the final chips. As a result, manufacturers invest heavily in advanced coater and developer machines to ensure the highest quality and efficiency in their production processes. In integrated circuit (IC) manufacturing, coaters and developers play a similar role. ICs are the building blocks of most electronic devices, and their production requires highly precise and controlled photolithography processes. Coater and developer machines are used to apply and develop the photoresist layers that define the intricate circuit patterns on the silicon wafers. The accuracy and consistency of these machines are critical for producing ICs with the desired electrical properties and performance characteristics. In addition to chip and IC manufacturing, the Global Coater and Developer Market also serves other specialized applications. These include the production of microelectromechanical systems (MEMS), sensors, and other advanced semiconductor devices. Each of these applications has unique requirements for the coating and developing process, and manufacturers often need specialized equipment to meet these needs. For example, MEMS devices, which are used in a wide range of applications from automotive systems to medical devices, require highly precise and uniform coatings to ensure their proper functioning. Similarly, sensors used in various industries, including consumer electronics and industrial automation, rely on advanced coater and developer machines to achieve the necessary performance and reliability. Overall, the Global Coater and Developer Market plays a vital role in enabling the production of a wide range of semiconductor devices. The precision and efficiency of the coating and developing process are critical for ensuring the quality and performance of these devices. As technology continues to advance, the demand for more sophisticated and capable coater and developer machines is expected to grow, driving further innovation and development in this market.

Global Coater and Developer Market Outlook:

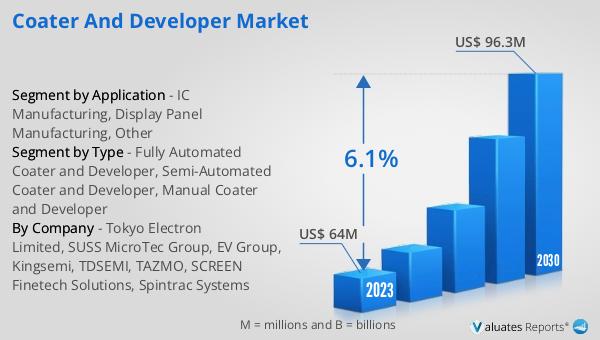

The global Coater and Developer market, valued at US$ 64 million in 2023, is projected to grow significantly, reaching an estimated US$ 96.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. The market's expansion is driven by the increasing demand for advanced semiconductor devices, which require highly precise and efficient photolithography processes. As the semiconductor industry continues to evolve, the need for more sophisticated coater and developer machines becomes more critical. These machines are essential for applying and developing photoresist layers on silicon wafers, a key step in the production of semiconductor devices. The market is characterized by intense competition, with several key players striving to offer the most advanced and reliable equipment. Continuous innovation and development in this market are essential to meet the changing needs of the semiconductor industry. The move towards smaller and more complex chip designs further drives the demand for advanced coater and developer machines. Overall, the global Coater and Developer market is poised for significant growth, playing a crucial role in the semiconductor manufacturing ecosystem.

| Report Metric | Details |

| Report Name | Coater and Developer Market |

| Accounted market size in 2023 | US$ 64 million |

| Forecasted market size in 2030 | US$ 96.3 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tokyo Electron Limited, SCREEN Semiconductor Solutions, SEMES, SÜSS MicroTec, TAZMO, C&D Semiconductor, Scientific Value Solutions, SurplusGLOBAL, KINGSEMI, Els System Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |