What is Global Cargo Picking Robot Market?

The Global Cargo Picking Robot Market refers to the industry focused on the development, production, and deployment of robots designed to pick and handle cargo. These robots are used in various sectors to automate the process of selecting and moving goods, which can significantly enhance efficiency and reduce labor costs. The market encompasses a wide range of technologies and solutions, including fully automated systems and semi-automated systems that require some human intervention. The primary drivers for this market include the increasing demand for automation in logistics and warehousing, the need for faster and more accurate order fulfillment, and the growing e-commerce sector. As businesses strive to improve their operational efficiency and meet the rising consumer expectations for quick delivery, the adoption of cargo picking robots is expected to grow. These robots are equipped with advanced sensors, artificial intelligence, and machine learning algorithms to navigate complex environments and handle various types of cargo with precision. The market is also witnessing innovations in robot design and functionality, making them more adaptable and capable of performing a wider range of tasks.

Automatic Type, Semi-automatic Type in the Global Cargo Picking Robot Market:

In the Global Cargo Picking Robot Market, there are two main types of robots: Automatic and Semi-automatic. Automatic cargo picking robots are fully autonomous systems that can operate without human intervention. These robots are equipped with advanced technologies such as artificial intelligence, machine learning, and sophisticated sensors that allow them to navigate complex environments, identify and pick items, and transport them to designated locations. They are designed to handle repetitive tasks with high precision and speed, making them ideal for large-scale operations in warehouses and distribution centers. These robots can work around the clock, significantly increasing productivity and reducing the need for manual labor. On the other hand, Semi-automatic cargo picking robots require some level of human intervention. These robots are typically used in environments where full automation is not feasible or cost-effective. Semi-automatic robots assist human workers by performing specific tasks such as lifting heavy items, transporting goods over short distances, or sorting items based on predefined criteria. They are equipped with sensors and control systems that allow them to work collaboratively with humans, enhancing overall efficiency and reducing the physical strain on workers. Both types of robots offer distinct advantages and can be deployed based on the specific needs and constraints of the operation. The choice between automatic and semi-automatic robots depends on factors such as the scale of the operation, the complexity of the tasks, and the available budget. As technology continues to advance, the capabilities of both automatic and semi-automatic cargo picking robots are expected to improve, offering even greater efficiency and flexibility to businesses.

Logistics Industry, Supermarket Warehouse, Others in the Global Cargo Picking Robot Market:

The usage of cargo picking robots in the logistics industry has revolutionized the way goods are handled and transported. In logistics, these robots are used to automate the process of picking, sorting, and transporting items within warehouses and distribution centers. They help in reducing the time and effort required for manual handling, thereby increasing efficiency and accuracy. Cargo picking robots can work continuously without breaks, ensuring that operations run smoothly and orders are fulfilled quickly. In supermarket warehouses, cargo picking robots play a crucial role in managing inventory and ensuring that products are readily available for restocking shelves. These robots can navigate through the warehouse, identify items that need to be picked, and transport them to the designated areas for packaging and shipping. This not only speeds up the process but also reduces the chances of errors, ensuring that the right products are delivered to the right locations. In addition to logistics and supermarket warehouses, cargo picking robots are also used in other industries such as manufacturing, retail, and healthcare. In manufacturing, these robots can be used to handle raw materials and finished products, streamlining the production process and reducing the risk of damage. In retail, cargo picking robots can assist in managing inventory and fulfilling online orders, ensuring that customers receive their products on time. In healthcare, these robots can be used to transport medical supplies and equipment, reducing the workload on healthcare professionals and ensuring that critical items are always available. Overall, the usage of cargo picking robots across various industries has led to significant improvements in efficiency, accuracy, and productivity, making them an essential component of modern supply chain management.

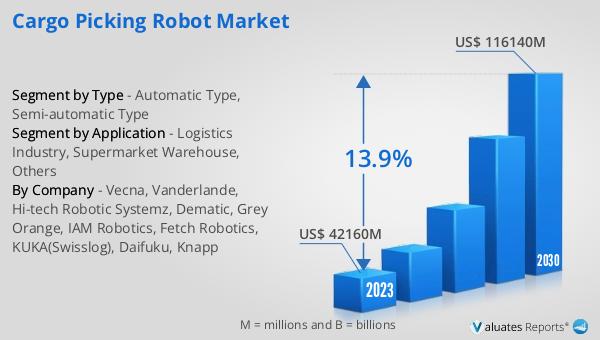

Global Cargo Picking Robot Market Outlook:

The global Cargo Picking Robot market was valued at US$ 42,160 million in 2023 and is projected to reach US$ 116,140 million by 2030, reflecting a compound annual growth rate (CAGR) of 13.9% during the forecast period from 2024 to 2030. This substantial growth indicates a strong demand for automation solutions in various industries, driven by the need for increased efficiency, accuracy, and cost savings. The adoption of cargo picking robots is expected to rise as businesses seek to improve their operational capabilities and meet the growing consumer expectations for faster and more reliable delivery services. The market's expansion is also fueled by advancements in technology, such as artificial intelligence, machine learning, and robotics, which are enhancing the capabilities and performance of these robots. As a result, more companies are investing in cargo picking robots to streamline their operations, reduce labor costs, and stay competitive in the market. The increasing focus on sustainability and reducing carbon footprints is also contributing to the market's growth, as automated systems can optimize resource usage and minimize waste. Overall, the global Cargo Picking Robot market is poised for significant growth, driven by the continuous advancements in technology and the rising demand for efficient and reliable automation solutions.

| Report Metric | Details |

| Report Name | Cargo Picking Robot Market |

| Accounted market size in 2023 | US$ 42160 million |

| Forecasted market size in 2030 | US$ 116140 million |

| CAGR | 13.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vecna, Vanderlande, Hi-tech Robotic Systemz, Dematic, Grey Orange, IAM Robotics, Fetch Robotics, KUKA(Swisslog), Daifuku, Knapp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |