What is Global Aluminum Foil Honeycomb Market?

The Global Aluminum Foil Honeycomb Market refers to the worldwide industry involved in the production, distribution, and utilization of aluminum foil honeycomb structures. These structures are made by bonding layers of aluminum foil into a honeycomb pattern, creating a lightweight yet strong material. This market encompasses various applications, including construction, aerospace, automotive, and other industries that require materials with high strength-to-weight ratios. The aluminum foil honeycomb is valued for its excellent mechanical properties, such as high stiffness, corrosion resistance, and thermal insulation. It is used in a variety of products, from aircraft panels to building facades, due to its ability to provide structural integrity while minimizing weight. The market is driven by the increasing demand for lightweight and durable materials in various sectors, as well as advancements in manufacturing technologies that enhance the performance and cost-effectiveness of aluminum foil honeycomb products.

Punching Type, Surface Coating Type in the Global Aluminum Foil Honeycomb Market:

In the Global Aluminum Foil Honeycomb Market, there are different types of products based on their manufacturing processes and surface treatments. One of the primary types is the Punching Type. This type involves creating the honeycomb structure by punching holes into aluminum sheets and then expanding them into a honeycomb pattern. The punching process ensures precision and uniformity in the honeycomb cells, which is crucial for applications requiring consistent mechanical properties. Punching Type aluminum foil honeycomb is widely used in industries where high strength and lightweight materials are essential, such as aerospace and automotive sectors. The precision in the punching process allows for the creation of honeycomb structures with specific cell sizes and densities, catering to various application needs. Another significant type in the market is the Surface Coating Type. This involves applying different coatings to the aluminum foil honeycomb to enhance its properties. Surface coatings can provide additional benefits such as improved corrosion resistance, increased thermal insulation, and enhanced aesthetic appeal. For instance, coatings like epoxy or polyester can be applied to the honeycomb structure to protect it from harsh environmental conditions, making it suitable for outdoor applications in the construction industry. Additionally, surface coatings can also improve the bonding strength between the honeycomb and other materials, ensuring better structural integrity in composite applications. The combination of Punching Type and Surface Coating Type products in the Global Aluminum Foil Honeycomb Market allows manufacturers to offer a wide range of solutions tailored to specific industry requirements. For example, in the aerospace industry, where weight reduction and structural strength are critical, the use of precision-punched honeycomb structures with specialized coatings can significantly enhance the performance of aircraft components. Similarly, in the construction industry, aluminum foil honeycomb panels with weather-resistant coatings can provide durable and lightweight solutions for building facades and interior partitions. The advancements in manufacturing technologies have also played a crucial role in the development of these product types. Modern punching machines and coating techniques have enabled the production of high-quality aluminum foil honeycomb structures with improved consistency and performance. These technological advancements have not only increased the efficiency of the manufacturing process but also reduced production costs, making aluminum foil honeycomb products more accessible to a broader range of industries. In conclusion, the Global Aluminum Foil Honeycomb Market offers a diverse range of products based on different manufacturing processes and surface treatments. The Punching Type and Surface Coating Type products cater to various industry needs, providing lightweight, strong, and durable solutions for applications in aerospace, construction, automotive, and other sectors. The continuous advancements in manufacturing technologies further enhance the performance and cost-effectiveness of these products, driving the growth and adoption of aluminum foil honeycomb structures in the global market.

Achitechive, Aerospace, Others in the Global Aluminum Foil Honeycomb Market:

The Global Aluminum Foil Honeycomb Market finds extensive usage in various sectors, including architecture, aerospace, and others. In the architectural sector, aluminum foil honeycomb panels are widely used for building facades, interior partitions, and ceilings. The lightweight nature of these panels makes them easy to handle and install, reducing construction time and labor costs. Additionally, the high strength-to-weight ratio of aluminum foil honeycomb panels provides excellent structural integrity, ensuring the durability and safety of buildings. The panels can also be coated with various finishes to enhance their aesthetic appeal, making them a popular choice for modern architectural designs. Furthermore, the thermal insulation properties of aluminum foil honeycomb panels contribute to energy efficiency in buildings, reducing heating and cooling costs. In the aerospace sector, aluminum foil honeycomb structures are used in the manufacturing of aircraft components such as fuselage panels, wings, and interior partitions. The lightweight and high-strength properties of aluminum foil honeycomb make it an ideal material for aerospace applications, where weight reduction is crucial for fuel efficiency and overall performance. The honeycomb structure provides excellent impact resistance and energy absorption, enhancing the safety and reliability of aircraft. Additionally, the thermal insulation properties of aluminum foil honeycomb help in maintaining temperature control within the aircraft, ensuring passenger comfort and safety. The use of aluminum foil honeycomb in aerospace applications also contributes to the overall reduction of greenhouse gas emissions by improving fuel efficiency. Apart from architecture and aerospace, the Global Aluminum Foil Honeycomb Market also finds applications in other sectors such as automotive, marine, and industrial manufacturing. In the automotive industry, aluminum foil honeycomb structures are used in the production of lightweight and high-strength components such as car body panels, bumpers, and interior parts. The use of aluminum foil honeycomb in automotive applications helps in reducing the overall weight of vehicles, improving fuel efficiency, and reducing emissions. In the marine industry, aluminum foil honeycomb panels are used in the construction of lightweight and durable boat hulls, decks, and bulkheads. The corrosion resistance properties of aluminum foil honeycomb make it suitable for marine environments, ensuring the longevity and performance of marine vessels. In industrial manufacturing, aluminum foil honeycomb structures are used in the production of lightweight and strong components for machinery, equipment, and transportation systems. The high strength-to-weight ratio of aluminum foil honeycomb provides excellent load-bearing capacity, making it suitable for heavy-duty applications. Additionally, the thermal insulation properties of aluminum foil honeycomb help in maintaining temperature control in industrial processes, improving efficiency and productivity. The versatility and performance of aluminum foil honeycomb make it a valuable material in various industrial applications, driving its demand in the global market. In conclusion, the Global Aluminum Foil Honeycomb Market finds extensive usage in architecture, aerospace, automotive, marine, and industrial manufacturing sectors. The lightweight, high-strength, and thermal insulation properties of aluminum foil honeycomb make it an ideal material for various applications, contributing to improved performance, efficiency, and sustainability. The continuous advancements in manufacturing technologies further enhance the versatility and cost-effectiveness of aluminum foil honeycomb products, driving their adoption in the global market.

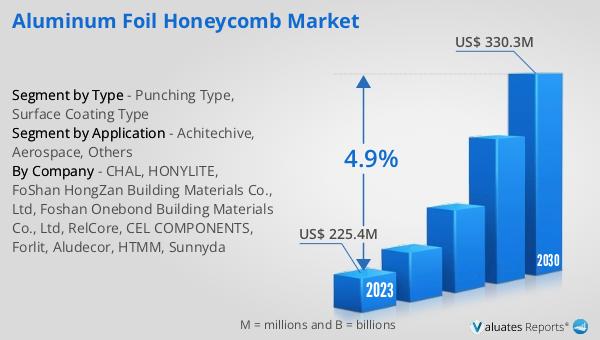

Global Aluminum Foil Honeycomb Market Outlook:

The global Aluminum Foil Honeycomb market was valued at US$ 225.4 million in 2023 and is anticipated to reach US$ 330.3 million by 2030, witnessing a CAGR of 4.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the aluminum foil honeycomb industry over the next several years. The increasing demand for lightweight and durable materials across various sectors, including aerospace, construction, and automotive, is a significant driver of this growth. The market's valuation in 2023 reflects the current demand and utilization of aluminum foil honeycomb products, while the projected value for 2030 highlights the potential for expansion and increased adoption of these materials. The compound annual growth rate (CAGR) of 4.9% suggests a consistent and healthy growth pattern, driven by technological advancements in manufacturing processes and the development of new applications for aluminum foil honeycomb structures. This growth rate also indicates the market's resilience and ability to adapt to changing industry needs and economic conditions. The anticipated increase in market value underscores the importance of aluminum foil honeycomb products in various high-performance applications, where their unique properties offer significant advantages over traditional materials. In summary, the global Aluminum Foil Honeycomb market is poised for substantial growth, with a projected increase in market value from US$ 225.4 million in 2023 to US$ 330.3 million by 2030. The steady CAGR of 4.9% during the forecast period reflects the ongoing demand for lightweight, strong, and versatile materials in multiple industries. This market outlook highlights the potential for innovation and expansion in the aluminum foil honeycomb sector, driven by advancements in manufacturing technologies and the development of new applications.

| Report Metric | Details |

| Report Name | Aluminum Foil Honeycomb Market |

| Accounted market size in 2023 | US$ 225.4 million |

| Forecasted market size in 2030 | US$ 330.3 million |

| CAGR | 4.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CHAL, HONYLITE, FoShan HongZan Building Materials Co., Ltd, Foshan Onebond Building Materials Co., Ltd, RelCore, CEL COMPONENTS, Forlit, Aludecor, HTMM, Sunnyda |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |