What is Global Wafer In-Process Containers Market?

The Global Wafer In-Process Containers Market is a specialized segment within the semiconductor industry, focusing on the production and supply of containers used for the safe and efficient handling of silicon wafers during the manufacturing process. These containers are crucial for protecting the wafers from contamination and damage as they are transported between various processing steps. The market caters to the needs of semiconductor fabrication plants where wafers undergo numerous processes such as doping, etching, and layer deposition to create integrated circuits. The demand for these containers is directly influenced by the semiconductor industry's growth, driven by the increasing demand for electronic devices, advancements in technology, and the expansion of applications for semiconductors in various sectors including automotive, healthcare, and telecommunications. As the industry moves towards more sophisticated and miniaturized components, the requirements for wafer handling and protection become more stringent, further emphasizing the importance of in-process containers. This market segment is characterized by its focus on material innovation, product integrity, and process integration, ensuring that the evolving needs of semiconductor manufacturing are met with precision and reliability.

PC Resin Materials, PBT Resin Materials, Others in the Global Wafer In-Process Containers Market:

Diving into the specifics of the Global Wafer In-Process Containers Market, it's essential to understand the role of different materials used in the production of these containers, namely PC Resin Materials, PBT Resin Materials, among others. PC (Polycarbonate) Resin Materials are favored for their exceptional clarity, impact resistance, and high temperature tolerance, making them ideal for environments where visual inspection of the wafer is necessary without compromising the container's integrity. On the other hand, PBT (Polybutylene Terephthalate) Resin Materials are known for their strength, stiffness, and excellent resistance to chemicals and moisture, which is crucial in preventing contamination of the wafers. These materials also exhibit low absorption of moisture, ensuring that the wafers remain dry and uncontaminated during processing and transport. Other materials used in the market may include specialized plastics and composites designed to meet specific requirements such as electrostatic discharge protection, which is critical in preventing damage to the sensitive electronic circuits on the wafers. The choice of material impacts not only the protection offered to the wafers but also the containers' compatibility with different environments and processes within the semiconductor manufacturing workflow. Manufacturers in the Global Wafer In-Process Containers Market continuously innovate and adapt their offerings to meet the stringent requirements of the semiconductor industry, ensuring that each material chosen offers the optimal balance of protection, durability, and cost-effectiveness.

300 mm Wafer, 200 mm Wafer, Others in the Global Wafer In-Process Containers Market:

The usage of Global Wafer In-Process Containers in the semiconductor industry is segmented mainly by the size of the wafers they are designed to protect, such as 300 mm wafers, 200 mm wafers, among others. Containers designed for 300 mm wafers are crucial in today's semiconductor manufacturing processes, as they cater to the industry's shift towards larger wafer sizes to increase yield and reduce costs. These containers are engineered to provide maximum protection for the wafers, which are more susceptible to damage due to their larger surface area. They ensure a controlled environment that minimizes the risk of contamination and physical damage during the transport and storage phases of the manufacturing process. On the other hand, containers for 200 mm wafers, although catering to a segment that is gradually being phased out in favor of larger diameters, remain relevant for specific applications and legacy systems that still rely on this wafer size. The 'Others' category includes containers designed for smaller or non-standard sizes, catering to niche applications or specialized semiconductor manufacturing processes. Each container type is designed with specific materials and features to address the unique challenges posed by the different wafer sizes, including structural integrity, contamination control, and compatibility with automation systems used in semiconductor fabs. The careful design and application of these containers play a pivotal role in the efficiency and success of the semiconductor manufacturing process, directly impacting the quality and reliability of the final electronic components.

Global Wafer In-Process Containers Market Outlook:

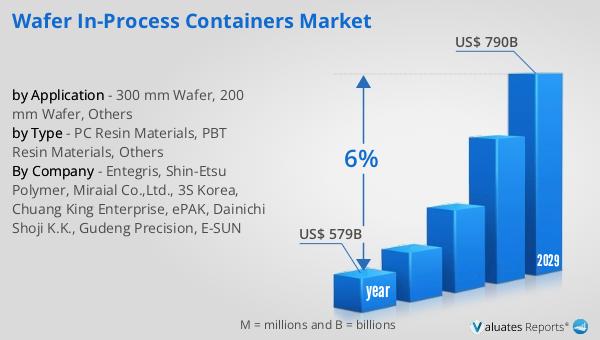

The market outlook for the semiconductor industry presents a promising future, with the sector's value estimated at US$ 579 billion in 2022, and projections suggesting growth to US$ 790 billion by 2029. This growth, expected to occur at a compound annual growth rate (CAGR) of 6% during the forecast period, reflects the industry's robust dynamics and its critical role in the global economy. The semiconductor market's expansion is fueled by the relentless demand for electronic devices, the continuous innovation in technology, and the broadening scope of semiconductor applications across various industries. This growth trajectory underscores the importance of the semiconductor industry as a cornerstone of technological advancement and economic development. It highlights the sector's resilience and adaptability in meeting the evolving demands of consumers and industries alike. As the market continues to grow, it will likely drive further innovations, leading to more efficient manufacturing processes, the development of new materials, and the introduction of more sophisticated products, ensuring the semiconductor industry remains at the forefront of technological progress.

| Report Metric | Details |

| Report Name | Wafer In-Process Containers Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2024 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entegris, Shin-Etsu Polymer, Miraial Co.,Ltd., 3S Korea, Chuang King Enterprise, ePAK, Dainichi Shoji K.K., Gudeng Precision, E-SUN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |