What is Global Vertical Rubber Injection Molding Machinery Market?

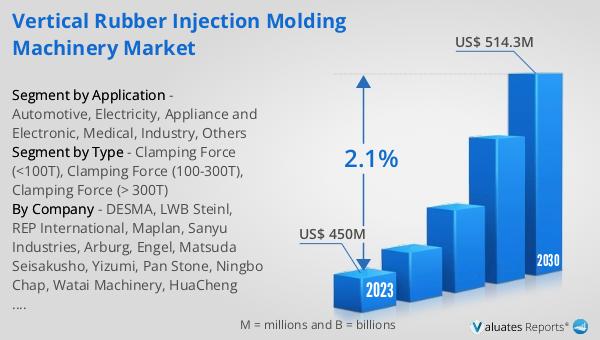

The Global Vertical Rubber Injection Molding Machinery Market is a specialized sector within the manufacturing industry, focusing on machinery designed for the injection molding of rubber components. This market caters to the production needs of various industries by providing machines that can precisely mold rubber into desired shapes and sizes. These machines operate vertically, which is a key feature distinguishing them from horizontal counterparts, offering advantages in terms of space efficiency and ease of operation for certain types of rubber products. The vertical orientation is particularly beneficial for inserting parts into the mold and removing finished products, making it a preferred choice for producing complex rubber parts. As of 2023, the market has been valued at US$ 450 million, showcasing its significant role in the global manufacturing landscape. With a projected growth rate of 2.1% from 2024 to 2030, it is expected to reach a valuation of US$ 514.3 million by the end of the forecast period. This growth is indicative of the increasing demand for rubber components across various applications, driving the need for efficient and reliable rubber injection molding machinery.

Clamping Force (<100T), Clamping Force (100-300T), Clamping Force (> 300T) in the Global Vertical Rubber Injection Molding Machinery Market:

Diving into the specifics of the Global Vertical Rubber Injection Molding Machinery Market, it's essential to understand the categorization based on clamping force, which is a critical parameter in the injection molding process. Clamping force, measured in tons, essentially determines the pressure applied to keep the mold closed during the injection process. The market segments these machines into three main categories: Clamping Force (<100T), Clamping Force (100-300T), and Clamping Force (>300T). Machines with a clamping force of less than 100 tons are typically used for small, intricate rubber parts requiring precise molding and low pressure. These are ideal for producing components with fine details without the risk of damage during the molding process. The 100-300T range caters to a broader spectrum of products, offering a balance between precision and the ability to produce medium-sized parts. This range is versatile, serving a wide array of industries from automotive to consumer goods, where the requirements can vary significantly. Lastly, machines with a clamping force greater than 300 tons are designed for large-scale production. These are capable of handling large molds and producing substantial parts, making them suitable for industries like automotive and industrial machinery, where bigger rubber components are needed. Each category serves distinct market needs, highlighting the versatility and adaptability of vertical rubber injection molding machinery to cater to a wide range of product sizes and complexities.

Automotive, Electricity, Appliance and Electronic, Medical, Industry, Others in the Global Vertical Rubber Injection Molding Machinery Market:

The usage of Global Vertical Rubber Injection Molding Machinery spans across several key industries, reflecting the versatility and critical nature of rubber components in modern manufacturing. In the automotive sector, these machines are indispensable for producing a wide range of parts such as seals, gaskets, hoses, and bellows, which are essential for vehicle assembly and performance. The precision and reliability of vertical rubber injection molding machinery ensure that automotive components meet strict industry standards and durability requirements. In the realm of electricity, rubber parts such as insulators, connectors, and protective covers are manufactured using these machines, highlighting the importance of high-quality, reliable components in ensuring electrical safety and functionality. The appliance and electronic industries also benefit significantly from these machines, utilizing them to produce parts that require precise rubber molding, such as buttons, seals, and protective cases, ensuring the longevity and reliability of consumer products. The medical sector relies on this machinery for producing components that meet stringent hygiene and safety standards, including seals, tubes, and various medical devices, underscoring the machinery's capability to produce high-precision parts. Additionally, the broader industrial sector utilizes these machines for a myriad of applications, including the production of industrial seals, gaskets, and shock absorbers, demonstrating the machinery's adaptability to various production needs. Lastly, other sectors, encompassing a wide range of miscellaneous applications, further illustrate the extensive utility of vertical rubber injection molding machinery in producing high-quality rubber components across diverse industries.

Global Vertical Rubber Injection Molding Machinery Market Outlook:

The market outlook for the Global Vertical Rubber Injection Molding Machinery presents a promising future, with the sector's valuation at US$ 450 million in 2023, and an expected rise to US$ 514.3 million by 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 2.1% during the forecast period from 2024 to 2030, underscores the increasing reliance on and demand for rubber injection molding machinery across various industries. The anticipated growth reflects the industry's adaptation to evolving market needs, including the demand for more efficient, precise, and reliable machinery capable of meeting the complex requirements of modern manufacturing. As industries continue to seek out innovative solutions for rubber component production, the vertical rubber injection molding machinery market is poised to expand, further solidifying its crucial role in the global manufacturing landscape. This outlook not only highlights the market's current value but also its potential for continued growth and development, offering insights into the future direction of this specialized manufacturing sector.

| Report Metric | Details |

| Report Name | Vertical Rubber Injection Molding Machinery Market |

| Accounted market size in 2023 | US$ 450 million |

| Forecasted market size in 2030 | US$ 514.3 million |

| CAGR | 2.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DESMA, LWB Steinl, REP International, Maplan, Sanyu Industries, Arburg, Engel, Matsuda Seisakusho, Yizumi, Pan Stone, Ningbo Chap, Watai Machinery, HuaCheng Hydraulic Power, DEKUMA, Tianyuan Technology, Tung Yu Hydraulic Machinery, Hengyang Huayi Machinery, Jing Day Machinery Industrial, DOUSH, Tayu Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |