What is Global Single Crystal Growing Furnace Market?

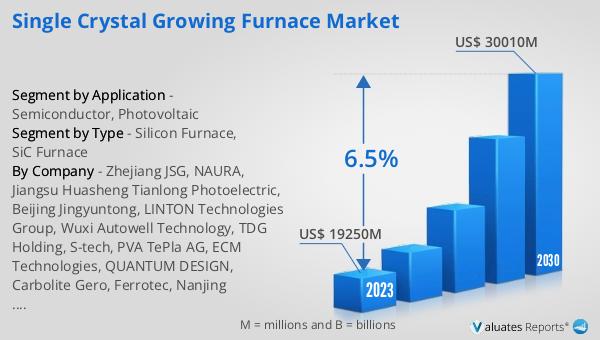

The Global Single Crystal Growing Furnace Market is a specialized sector within the broader market of equipment used for the production of single crystals, which are essential components in various high-tech industries. This market focuses on the devices and technologies used to grow single crystals of different materials, most notably silicon, through processes that ensure the purity and perfection of the crystal structure. These furnaces are critical in the manufacturing of semiconductors, solar cells, and other electronic devices, where the quality of the single crystal directly impacts the performance of the final product. As of 2023, the market has been valued at US$ 19,250 million, showcasing the significant investment and importance placed on advanced manufacturing technologies. With a projected Compound Annual Growth Rate (CAGR) of 6.5%, the market is expected to reach US$ 30,010 million by 2030. This growth is indicative of the increasing demand for high-quality single crystals in the production of sophisticated electronics and renewable energy solutions, reflecting broader trends in technological advancement and sustainability.

Silicon Furnace, SiC Furnace in the Global Single Crystal Growing Furnace Market:

Diving into the specifics, the Global Single Crystal Growing Furnace Market encompasses two primary types of furnaces: Silicon Furnaces and Silicon Carbide (SiC) Furnaces. Silicon Furnaces are predominantly used in the semiconductor industry for the production of single-crystal silicon ingots. These ingots are then sliced into wafers, serving as the foundational material for semiconductor devices. The process involves heating raw silicon until it melts, then carefully cooling it to form a single crystal. This method requires precise temperature control and a contaminant-free environment to ensure the purity and structural integrity of the crystal. On the other hand, SiC Furnaces cater to the growing demand for Silicon Carbide crystals, which are essential for high-power and high-frequency electronic devices. SiC crystals offer superior properties, such as higher thermal conductivity, greater electron mobility, and increased hardness, making them ideal for applications in electric vehicles, renewable energy systems, and military electronics. The production process in SiC Furnaces is more complex and challenging than that of silicon, given the higher temperatures required and the material's resistance to crystallization. Both types of furnaces play crucial roles in the Global Single Crystal Growing Furnace Market, addressing the needs of different segments within the electronics industry and driving innovation in material science and engineering.

Semiconductor, Photovoltaic in the Global Single Crystal Growing Furnace Market:

The usage of the Global Single Crystal Growing Furnace Market spans across two critical areas: the semiconductor industry and the photovoltaic sector. In the semiconductor realm, these furnaces are instrumental in producing the high-quality single crystals needed for semiconductor wafers. These wafers are the building blocks of integrated circuits, which are ubiquitous in today's electronic devices, from smartphones to computers and beyond. The precision and purity required for these crystals are paramount, as any imperfections can significantly impact the performance and reliability of the semiconductor devices. As the demand for more powerful and efficient electronics continues to rise, so does the need for advanced single crystal growing furnaces capable of meeting these stringent requirements. In the photovoltaic sector, single crystal growing furnaces are used to create the silicon crystals that form the basis of solar cells. These cells convert sunlight into electricity, and the efficiency of this conversion is heavily dependent on the quality of the silicon crystal. High-purity, defect-free crystals allow for more efficient light absorption and conversion, making the role of single crystal growing furnaces critical in the production of solar panels. As the world increasingly turns to renewable energy sources to combat climate change, the importance of these furnaces in enabling efficient solar power generation cannot be overstated.

Global Single Crystal Growing Furnace Market Outlook:

The market outlook for the Global Single Crystal Growing Furnace Market presents a promising future, with the market's value standing at US$ 19,250 million in 2023 and projected to ascend to US$ 30,010 million by 2030. This growth trajectory, marked by a Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period from 2024 to 2030, underscores the burgeoning demand and technological advancements within the sector. This expansion is further evidenced by the record-setting sales in the semiconductor manufacturing equipment sector, which surged from $102 billion in 2021 to an unprecedented $107.6 billion the following year, according to SEMI. This uptick in sales highlights the increasing investment in semiconductor manufacturing capabilities, driven by the global demand for more sophisticated and efficient electronic devices. The Single Crystal Growing Furnace Market is at the heart of this growth, providing the essential technology needed to produce the high-quality single crystals that form the foundation of both semiconductor and photovoltaic technologies. As such, the market's outlook is not only a reflection of its current state but also an indicator of the critical role it will continue to play in the advancement of electronic and renewable energy solutions.

| Report Metric | Details |

| Report Name | Single Crystal Growing Furnace Market |

| Accounted market size in 2023 | US$ 19250 million |

| Forecasted market size in 2030 | US$ 30010 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zhejiang JSG, NAURA, Jiangsu Huasheng Tianlong Photoelectric, Beijing Jingyuntong, LINTON Technologies Group, Wuxi Autowell Technology, TDG Holding, S-tech, PVA TePla AG, ECM Technologies, QUANTUM DESIGN, Carbolite Gero, Ferrotec, Nanjing Advanced Semiconductor Technology, Zhejiang YunFeng New Material Technology, ESTech, Shanghai Hanhong, Crystal Growth and Energy Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |