What is Global Shell & Tube Heat Exchanger Market?

The Global Shell & Tube Heat Exchanger Market is a specialized sector within the broader heat exchanger industry, focusing on the design, manufacturing, and application of shell and tube heat exchangers. These devices are critical for transferring heat between two or more fluids, making them indispensable in various industrial processes. The shell and tube design is particularly favored for its robustness, efficiency, and versatility, catering to a wide range of temperatures and pressures. This market's significance is underscored by its extensive application across multiple industries, including chemical processing, oil and gas, power generation, and more. As industries worldwide strive for more efficient and sustainable operations, the demand for advanced shell and tube heat exchangers is expected to rise, reflecting the market's dynamic nature and its critical role in global industrial infrastructure.

Cross Flow to Tubes, Parallel Flow to Tubes in the Global Shell & Tube Heat Exchanger Market:

In the realm of the Global Shell & Tube Heat Exchanger Market, the concepts of Cross Flow to Tubes and Parallel Flow to Tubes stand out for their distinct operational methodologies and applications. Cross Flow to Tubes heat exchangers are designed so that the fluid flows perpendicular to the tubes. This arrangement enhances the heat transfer efficiency by maximizing the temperature difference between the fluids over the entire length of the tubes. It's particularly beneficial in situations where a significant temperature change is required, and space is at a premium. On the other hand, Parallel Flow to Tubes heat exchangers feature both the tube-side and shell-side fluids moving in the same direction. This setup minimizes the potential for temperature cross-over and is typically used in applications where the fluids have a minimal temperature difference to begin with. Both these configurations are pivotal in the Global Shell & Tube Heat Exchanger Market, offering solutions tailored to a wide array of industrial needs. From chemical processing plants where aggressive fluids need efficient cooling, to power generation facilities where steam condensation is paramount, these designs facilitate critical heat exchange processes. Their significance is further magnified by the ongoing push for energy efficiency and reduced environmental impact across industries, making them key components in the global pursuit of sustainable industrial practices.

Chemicals, Petrochemicals and Oil & Gas, HVAC & Refrigeration, Food & Beverages, Power Generation, Pulp & Paper, Others in the Global Shell & Tube Heat Exchanger Market:

The Global Shell & Tube Heat Exchanger Market finds its applications sprawling across a diverse range of industries, each with its unique requirements and challenges. In the chemical sector, these heat exchangers are pivotal for controlling process temperatures and facilitating chemical reactions, ensuring safety and efficiency. The petrochemicals and oil & gas industries rely on them for cooling, condensing, and heating various process streams, a critical aspect of refining and processing operations. HVAC & refrigeration systems utilize shell and tube heat exchangers to efficiently transfer heat, crucial for maintaining desired temperatures in buildings and industrial processes. The food & beverages industry benefits from their ability to precisely control process temperatures, essential for product quality and safety. Power generation plants use these exchangers for steam condensation and cooling in turbines, directly impacting efficiency and operational costs. In the pulp & paper industry, they are used for heating and cooling processes, affecting production speed and quality. Other sectors, including pharmaceuticals, marine, and water treatment, also leverage these heat exchangers for their efficiency and adaptability, underscoring the Global Shell & Tube Heat Exchanger Market's versatility and critical role in modern industrial operations.

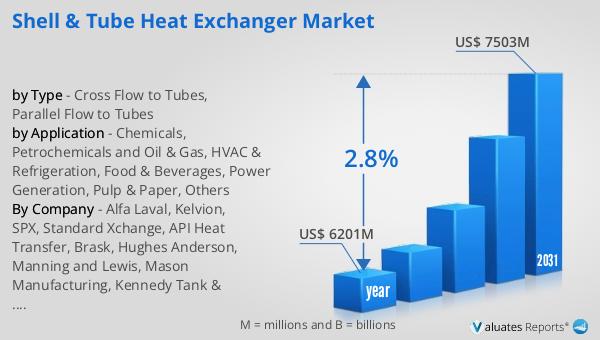

Global Shell & Tube Heat Exchanger Market Outlook:

The market outlook for the Global Shell & Tube Heat Exchanger sector presents a promising future. As of 2023, the market's valuation stood at approximately $5699.6 million, with projections suggesting a growth trajectory that could see it reach around $7138.8 million by the year 2030. This anticipated growth, marked by a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030, highlights the increasing demand and potential for shell and tube heat exchangers across various industries. Such growth is indicative of the sector's resilience and its pivotal role in supporting industrial processes by enhancing energy efficiency and operational effectiveness. The steady expansion reflects broader trends towards sustainability and efficiency in industrial operations, driving innovation and development within the Global Shell & Tube Heat Exchanger Market.

| Report Metric | Details |

| Report Name | Shell & Tube Heat Exchanger Market |

| Accounted market size in 2023 | US$ 5699.6 million |

| Forecasted market size in 2030 | US$ 7138.8 million |

| CAGR | 2.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alfa Laval, Kelvion, SPX, Standard Xchange, API Heat Transfer, Brask, Hughes Anderson, Manning and Lewis, Mason Manufacturing, Kennedy Tank & Manufacturing, Enerfin, Hrs Heat Exchangers, Koch Heat Transfer, Southern Heat Exchanger |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |