What is Global Rubber Molding Machines Market?

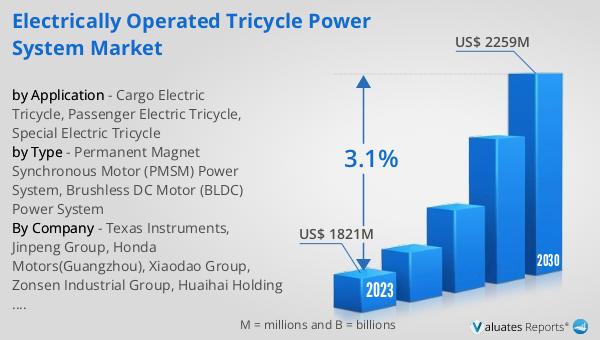

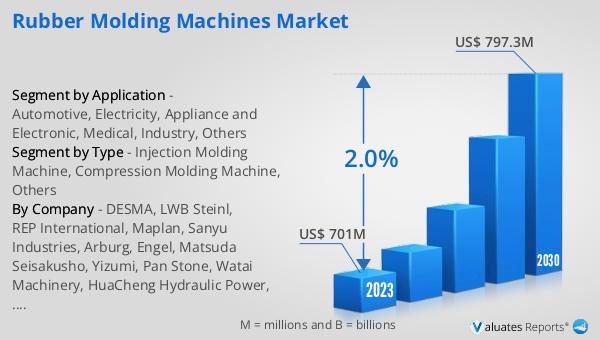

The Global Rubber Molding Machines Market encompasses a specialized sector dedicated to the production of rubber parts through various molding processes. These machines are pivotal in shaping rubber into desired forms by applying heat and pressure, a process essential for numerous industries. The market for these machines is significant due to the diverse applications of molded rubber parts, ranging from automotive components to household appliances. As of 2023, the market's valuation stood at approximately US$ 701 million, reflecting its critical role in global manufacturing and production lines. With advancements in technology and increasing demand for high-quality rubber components, the market is projected to grow, reaching an estimated value of US$ 797.3 million by 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 2.0% from 2024 to 2030, underscores the evolving needs of industries reliant on rubber parts and the innovation within rubber molding machine manufacturing to meet these demands.

Injection Molding Machine, Compression Molding Machine, Others in the Global Rubber Molding Machines Market:

Diving deeper into the Global Rubber Molding Machines Market, we find it segmented into various types based on the molding process, namely Injection Molding Machine, Compression Molding Machine, and others. Injection Molding Machines are highly favored for their precision and efficiency, allowing for the production of complex shapes with consistent quality. These machines work by injecting molten rubber into a mold cavity, which then cools and solidifies into the final product. On the other hand, Compression Molding Machines are traditional yet versatile, suitable for manufacturing a wide range of products. This process involves placing a rubber compound into a heated mold, which is then closed under pressure, causing the rubber to take the shape of the mold. Other types of rubber molding machines include transfer molding machines, which combine aspects of both injection and compression molding, offering unique benefits for specific applications. Each type of machine caters to different production needs, from high-volume manufacturing to creating intricate parts, reflecting the diverse requirements across industries that utilize rubber components. The selection of a machine type is crucial, depending on factors such as desired product complexity, production speed, and cost-effectiveness, highlighting the tailored approach within the Global Rubber Molding Machines Market to meet varied manufacturing demands.

Automotive, Electricity, Appliance and Electronic, Medical, Industry, Others in the Global Rubber Molding Machines Market:

The usage of Global Rubber Molding Machines Market spans across several critical sectors, including Automotive, Electricity, Appliance and Electronic, Medical, Industry, and Others. In the automotive sector, these machines are indispensable for producing a myriad of rubber components like seals, gaskets, and hoses, which are essential for vehicle functionality and safety. The electricity sector relies on molded rubber parts for insulating and protective components, ensuring the reliable transmission and distribution of power. Similarly, in the appliance and electronic industries, rubber molding machines are used to create durable and heat-resistant parts, such as buttons, seals, and protective covers, which are integral to the longevity and performance of electronic devices. The medical field benefits from the precision and hygiene offered by rubber molding processes, producing components like seals, valves, and tubes used in various medical devices. The broader industrial sector utilizes these machines for manufacturing parts that are critical to machinery and equipment, highlighting the versatility and importance of rubber components across different applications. This widespread usage underscores the integral role of the Global Rubber Molding Machines Market in supporting the operational needs of diverse industries, driving the demand for advanced and efficient molding solutions.

Global Rubber Molding Machines Market Outlook:

Regarding the market outlook for the Global Rubber Molding Machines Market, it's observed that the sector has shown a promising valuation of US$ 701 million as of 2023. This figure is expected to ascend to US$ 797.3 million by the year 2030, marking a steady compound annual growth rate (CAGR) of 2.0% throughout the forecast period spanning from 2024 to 2030. This growth is indicative of the increasing reliance on rubber molding machines across various industries for the production of high-quality rubber components. The upward trajectory in the market's value reflects the ongoing advancements in molding technologies and the expanding applications of rubber parts in sectors such as automotive, electronics, medical, and more. The steady growth rate also highlights the resilience and adaptability of the market in meeting the evolving demands for rubber products, ensuring its significance in the global manufacturing landscape. This optimistic outlook underscores the potential for innovation and expansion within the Global Rubber Molding Machines Market, catering to the future needs of industries reliant on rubber components.

| Report Metric | Details |

| Report Name | Rubber Molding Machines Market |

| Accounted market size in 2023 | US$ 701 million |

| Forecasted market size in 2030 | US$ 797.3 million |

| CAGR | 2.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DESMA, LWB Steinl, REP International, Maplan, Sanyu Industries, Arburg, Engel, Matsuda Seisakusho, Yizumi, Pan Stone, Watai Machinery, HuaCheng Hydraulic Power, DEKUMA, Tianyuan Technology, Tung Yu Hydraulic Machinery, Hengyang Huayi Machinery, Jing Day Machinery Industrial, DOUSH, Ningbo Chap, Tayu Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |