What is Global Non-Cryogenic Air Separation Plants Market?

The Global Non-Cryogenic Air Separation Plants Market refers to the industry focused on the production of industrial gases without the use of cryogenic distillation techniques. These plants utilize alternative methods such as pressure swing adsorption (PSA), vacuum pressure swing adsorption (VPSA), and membrane separation to separate air into its primary components - mainly oxygen, nitrogen, and argon. Unlike their cryogenic counterparts, non-cryogenic plants operate at near-ambient temperatures, making them more energy-efficient and suitable for on-site production where smaller volumes or lower purities of gas are required. This market caters to a wide range of industries, including healthcare, food and beverage, metal production, and chemical manufacturing, offering customized solutions to meet specific purity and flow rate needs. As industries worldwide strive for more sustainable and cost-effective production methods, the demand for non-cryogenic air separation plants is expected to grow, driven by their lower energy consumption and operational flexibility.

Selective Adsorption, Differential Permutation through Membranes, Others in the Global Non-Cryogenic Air Separation Plants Market:

Selective Adsorption, Differential Permutation through Membranes, and Others are key technologies underpinning the Global Non-Cryogenic Air Separation Plants Market. Selective Adsorption, particularly Pressure Swing Adsorption (PSA), involves adsorbing components of air under high pressure onto a material with a large surface area, then releasing them under lower pressure to separate out gases like oxygen and nitrogen. This method is highly efficient for producing high-purity gases on a smaller scale, making it ideal for on-site applications in various industries. Differential Permutation through Membranes, on the other hand, separates gases based on their molecular sizes and solubility through specially designed membranes. This technology is particularly useful for generating nitrogen and oxygen-enriched air directly on-site, offering a compact and cost-effective solution for moderate purity requirements. Other emerging technologies in this market include Vacuum Pressure Swing Adsorption (VPSA), which operates similarly to PSA but under vacuum to enhance efficiency and lower energy consumption. These technologies collectively support a wide range of applications, from medical oxygen to nitrogen for food packaging, highlighting their versatility and adaptability to meet specific industry needs. The continuous advancement in these technologies is pivotal in driving the non-cryogenic air separation plants market forward, offering more sustainable, energy-efficient, and tailored solutions for gas production.

Metallurgy, Oil and Gas, Chemicals, Healthcare in the Global Non-Cryogenic Air Separation Plants Market:

The Global Non-Cryogenic Air Separation Plants Market plays a crucial role in several key industries, including Metallurgy, Oil and Gas, Chemicals, and Healthcare, by providing essential industrial gases. In Metallurgy, non-cryogenic plants supply oxygen for metal processing and refining, enhancing combustion and reducing impurities in metals. This is vital for producing high-quality steel and other metals. In the Oil and Gas sector, nitrogen produced from these plants is used for pipeline purging, pressure testing, and inerting to ensure operational safety and efficiency. The Chemical industry benefits from the precise control over oxygen and nitrogen purity levels, crucial for various chemical reactions and processes, ensuring product quality and safety. Healthcare is another significant beneficiary, with non-cryogenic plants providing medical-grade oxygen for hospitals and healthcare facilities, especially critical in remote or emergency situations where traditional supply methods are impractical. These applications underscore the versatility and importance of non-cryogenic air separation plants across diverse sectors, highlighting their role in supporting industrial processes, safety, and healthcare services.

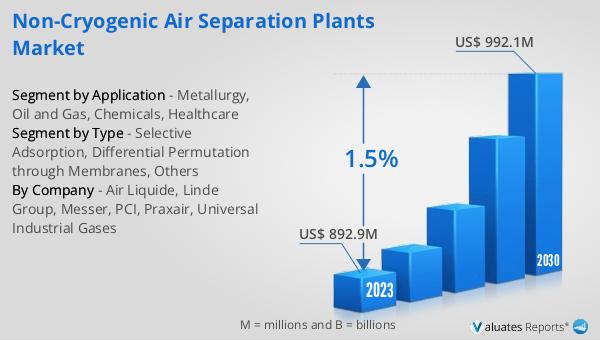

Global Non-Cryogenic Air Separation Plants Market Outlook:

The market outlook for the Global Non-Cryogenic Air Separation Plants Market presents a positive trajectory, with the market's value estimated at US$ 892.9 million in 2023, and projections suggest it will ascend to US$ 992.1 million by 2030. This growth, expected to unfold at a compound annual growth rate (CAGR) of 1.5% during the forecast period from 2024 to 2030, underscores the increasing demand for non-cryogenic air separation technologies. The market's expansion is attributed to the rising need for energy-efficient and cost-effective gas production methods across various industries. As businesses continue to seek environmentally friendly and sustainable operations, the adoption of non-cryogenic air separation plants is anticipated to rise, driven by their advantages over traditional cryogenic methods, including lower energy requirements and the capability for on-site production. This outlook reflects the market's potential for steady growth as industries worldwide transition towards more sustainable manufacturing and processing practices.

| Report Metric | Details |

| Report Name | Non-Cryogenic Air Separation Plants Market |

| Accounted market size in 2023 | US$ 892.9 million |

| Forecasted market size in 2030 | US$ 992.1 million |

| CAGR | 1.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Air Liquide, Linde Group, Messer, PCI, Praxair, Universal Industrial Gases |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |