What is Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market?

The Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market is a specialized segment within the broader semiconductor equipment industry, focusing on a unique technology used to hold materials in place during the manufacturing process. Electrostatic chucks (ESCs) utilize electrical charges to attract and hold semiconductor wafers, glass substrates, or other materials, facilitating precision work on these items without physical contact. The JR type, named after its inventors, employs a combination of Coulomb forces and Johnsen-Rahbek forces to achieve stronger adhesion and better thermal conductivity, making it highly suitable for applications where heat transfer and secure holding are critical. This market's significance lies in its role in enhancing the efficiency and effectiveness of semiconductor manufacturing processes, contributing to the production of increasingly sophisticated and miniaturized electronic devices. As of 2023, the market has been valued at US$ 567.1 million, with projections suggesting growth to US$ 743.5 million by 2030, driven by advancements in technology and increasing demand for high-performance electronic devices.

CVD Equipment, PVD Equipment, IMP Equipment, ETCH Equipment, LITHO Equipment, Others in the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market:

In the realm of the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market, various equipment types such as CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), IMP (Ion Milling Process), ETCH, LITHO (Lithography), and others play pivotal roles. Each equipment type utilizes JR type ESCs differently, catering to specific requirements of semiconductor manufacturing processes. CVD equipment, for instance, relies on ESCs to hold substrates in place under high temperatures and reactive gases, ensuring uniform deposition of materials. PVD equipment, on the other hand, uses ESCs for sputtering or evaporation processes, where precise control over substrate positioning is crucial for thin-film deposition. IMP equipment benefits from the strong adhesion and thermal conductivity of JR type ESCs during the ion milling process, enhancing the precision of material removal. ETCH equipment, which involves removing layers from the semiconductor wafer, requires the stability and reliability offered by JR type ESCs to achieve high precision in patterning. LITHO equipment, essential for transferring microscopic patterns onto wafers, also depends on the accurate positioning and thermal management capabilities of JR type ESCs. Other semiconductor manufacturing equipment leveraging JR type ESCs includes those involved in inspection, testing, and packaging, highlighting the versatility and critical importance of these chucks across the semiconductor production landscape.

Fab, Semiconductor Equipment Factory in the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market:

The usage of the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market spans across various areas, notably in fabs and semiconductor equipment factories. In fabs, where the production of semiconductor devices takes place, JR type ESCs are indispensable for their superior holding power and thermal management capabilities. These chucks are utilized in numerous steps of the semiconductor manufacturing process, from wafer processing to inspection, ensuring that delicate semiconductor wafers are securely held in place without contamination or damage. Their ability to provide uniform heat distribution is particularly valuable in processes requiring precise temperature control, enhancing the quality and reliability of semiconductor devices. Similarly, in semiconductor equipment factories, where the machines used in fabs are designed and assembled, JR type ESCs play a crucial role in testing and calibrating equipment. They ensure that the equipment can accurately handle and process semiconductor materials, guaranteeing that when these machines are deployed in fabs, they perform their functions flawlessly. The widespread use of JR type ESCs in these areas underscores their importance in the semiconductor manufacturing ecosystem, contributing significantly to the advancement of technology and the production of high-quality electronic devices.

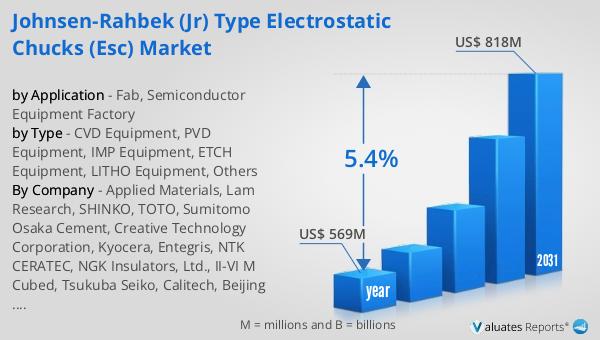

Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market Outlook:

The market outlook for the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market presents a promising future. As of 2023, the market's valuation stood at US$ 567.1 million, with expectations to ascend to US$ 743.5 million by the year 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 5.4% during the forecast period from 2024 to 2030, underscores the increasing reliance on and demand for JR type ESCs in the semiconductor manufacturing industry. Leading the market, Applied Materials has established a dominant presence with a 43.84% revenue market share, followed by Lam Research and SHINKO, holding 31.58% and 10.21% of the market share, respectively. This distribution of market shares highlights the competitive landscape, with key players driving innovation and adoption of JR type ESCs. The anticipated growth is reflective of the broader trends in the semiconductor industry, where the demand for more efficient, reliable, and high-performance manufacturing solutions is ever-increasing. As electronic devices become more sophisticated, the role of advanced manufacturing technologies, including JR type ESCs, becomes more critical, promising a robust market outlook for the coming years.

| Report Metric | Details |

| Report Name | Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market |

| Accounted market size in 2023 | US$ 567.1 million |

| Forecasted market size in 2030 | US$ 743.5 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, NTK CERATEC, NGK Insulators, Ltd., II-VI M Cubed, Tsukuba Seiko, Calitech, Beijing U-PRECISION TECH CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |