What is Global High Temperature Thermoplastics Market?

The Global High Temperature Thermoplastics Market encompasses a specialized group of polymers designed to withstand extreme temperatures without losing their structural integrity or performance characteristics. These materials are sought after in various industries due to their remarkable ability to operate in high-temperature environments, which traditional plastics cannot endure. The market for these advanced materials is significant, as they play a crucial role in applications where heat resistance is paramount. From automotive components that must resist engine heat to electronics that operate at high temperatures, these thermoplastics ensure reliability and durability. The demand for such materials is driven by the need for products that can maintain performance in extreme conditions, making them invaluable in sectors pushing the boundaries of material science. As industries continue to innovate and require materials that can withstand more demanding environments, the Global High Temperature Thermoplastics Market is expected to grow, reflecting the increasing importance of these advanced materials in modern applications.

High Temperature Fluoropolymers (High Temperature FPs), High Performance Polyamide (HPPA), Polyphenylene Sulfide (PPS), Sulfone Polymers (SP), Liquid Crystal Polymers (LCP), Aromatic Ketone Polymers (AKP), Poly-imide (PI) in the Global High Temperature Thermoplastics Market:

Diving into the specifics, the Global High Temperature Thermoplastics Market is segmented into various types, each with unique properties catering to different high-heat applications. High Temperature Fluoropolymers (FPs) are renowned for their exceptional chemical resistance and can operate in temperatures up to 260°C, making them ideal for harsh chemical environments. High Performance Polyamide (HPPA) offers excellent strength and stiffness at elevated temperatures, widely used in automotive and electrical components. Polyphenylene Sulfide (PPS) stands out for its dimensional stability and resistance to chemicals, serving well in automotive and aerospace parts. Sulfone Polymers (SP) are known for their transparency and toughness at high temperatures, commonly used in medical devices. Liquid Crystal Polymers (LCP) exhibit excellent flow properties and are used in precision parts in the electronics industry due to their high thermal stability. Aromatic Ketone Polymers (AKP) provide unmatched strength and resistance to high temperatures and are often found in aerospace and automotive applications. Lastly, Polyimide (PI) is celebrated for its ability to withstand extremely high temperatures, up to 400°C, making it perfect for insulation and semiconductor applications. Each of these materials contributes to the versatility and growth of the Global High Temperature Thermoplastics Market, catering to a wide range of industrial needs that require durability and performance in extreme conditions.

Transportation, Electrical & Electronics, Industrial, Medical, Others in the Global High Temperature Thermoplastics Market:

The usage of Global High Temperature Thermoplastics across various sectors highlights their versatility and critical role in modern industry. In transportation, these materials are used to manufacture components that must endure high temperatures and mechanical stress, such as under-the-hood parts. The electrical and electronics sector relies on these thermoplastics for components that offer reliability and performance at elevated temperatures, including connectors and insulating materials. Industrial applications benefit from the material's resistance to chemicals and heat, using them in machinery parts and industrial gears. The medical field utilizes these thermoplastics for their sterilization capabilities and high-performance characteristics in medical devices and equipment. Other areas, including consumer goods, also take advantage of the unique properties of high-temperature thermoplastics, incorporating them into products that require durability and heat resistance. This wide-ranging applicability underscores the importance of high-temperature thermoplastics in advancing technology and innovation across industries, driving the market's growth as demands for high-performance materials continue to rise.

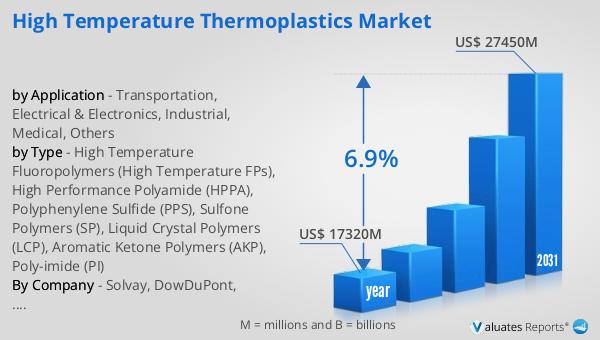

Global High Temperature Thermoplastics Market Outlook:

Regarding the market outlook for Global High Temperature Thermoplastics, it's observed that the market commenced with a valuation of US$ 14,760 million in 2023. It's projected to experience a notable growth trajectory, aiming to reach a valuation of US$ 24,330 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 6.9% throughout the forecast period spanning from 2024 to 2030. This projection underscores the increasing demand and expanding applications of high-temperature thermoplastics across various industries. The market's growth is fueled by the need for materials that can perform under extreme conditions, highlighting the critical role these polymers play in modern manufacturing and product development. As industries continue to push the boundaries of technology and material science, the reliance on high-temperature thermoplastics is expected to rise, driving the market towards its projected growth.

| Report Metric | Details |

| Report Name | High Temperature Thermoplastics Market |

| Accounted market size in 2023 | US$ 14760 million |

| Forecasted market size in 2030 | US$ 24330 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Solvay, DowDuPont, Celanese, BASF, Arkema, Royal Dsm, Sabic, Victrex, Evonik, Toray Industries, Freudenberg, DIC, Sumitomo Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |