What is Global High Temperature Resin Market?

The Global High Temperature Resin Market is a specialized sector that focuses on the production and distribution of resins capable of withstanding extreme temperatures without degrading. These resins are engineered to maintain structural integrity and functionality in environments that would typically compromise the quality of standard resins. The market's significance stems from its application across various industries where materials are exposed to high thermal conditions, including aerospace, automotive, and electronics, among others. As industries push the boundaries of innovation, requiring materials that can endure higher temperatures and harsher conditions, the demand for high-temperature resins has seen a substantial increase. This market encapsulates a range of resin types, each with unique properties and applications, catering to the specific needs of these high-stakes environments. With advancements in technology and material science, the Global High Temperature Resin Market is poised for growth, driven by the escalating requirements for materials that offer superior heat resistance, durability, and performance.

Phenolic, Epoxy, Thermoplastic, Polyimide, Benzoxazine, Cyanate Ester, Others in the Global High Temperature Resin Market:

Diving into the Global High Temperature Resin Market reveals a diverse array of resin types, each serving distinct purposes across various industries. Phenolic resins are known for their excellent thermal stability, flame resistance, and mechanical strength, making them ideal for high-heat applications in the aerospace and defense sectors. Epoxy resins, on the other hand, are widely appreciated for their strong adhesive properties, high chemical resistance, and superior mechanical performance, finding extensive use in the manufacturing of composite materials, coatings, and electronic components. Thermoplastic resins, including polyether ether ketone (PEEK) and polyphenylene sulfide (PPS), offer remarkable flexibility, ease of processing, and resistance to chemicals and heat, which are critical in automotive and electrical applications. Polyimide resins stand out for their ability to withstand extremely high temperatures, making them indispensable in the production of high-performance components for aerospace, electronics, and industrial machinery. Benzoxazine resins are emerging as a preferred choice due to their low shrinkage, excellent thermal properties, and resistance to flame and chemicals, suitable for advanced composites. Cyanate ester resins are recognized for their exceptional thermal stability and dielectric properties, which are essential for high-frequency electronic applications. The category labeled "Others" encompasses a variety of specialized resins that cater to niche applications requiring specific high-temperature performance characteristics. Together, these resin types form the backbone of the Global High Temperature Resin Market, addressing the evolving demands for materials that can perform under the most challenging conditions.

Aerospace & Defense, Transportation, Electrical & Electronics, Others in the Global High Temperature Resin Market:

The usage of Global High Temperature Resin Market spans across several critical sectors, showcasing the versatility and essential nature of these materials. In aerospace & defense, high-temperature resins are pivotal for manufacturing components that must endure the extreme conditions of flight and space exploration, including the internal parts of jet engines, where temperatures can soar. These resins provide the necessary thermal resistance, structural integrity, and lightweight properties crucial for modern aerospace applications. The transportation sector benefits from these resins in the production of automotive parts that are exposed to high heat, such as engine components, exhaust systems, and brake systems, enhancing vehicle performance and safety. In the realm of electrical & electronics, high-temperature resins are indispensable for creating components that can withstand the thermal stress of power generation, transmission, and storage, ensuring reliability and longevity of electronic devices and systems. Other industries, including industrial machinery, chemical processing, and construction, leverage these high-performance resins for their ability to maintain structural and functional integrity in high-temperature environments, contributing to the efficiency, durability, and safety of various applications. The widespread use of high-temperature resins across these sectors underscores their critical role in advancing technological and industrial capabilities.

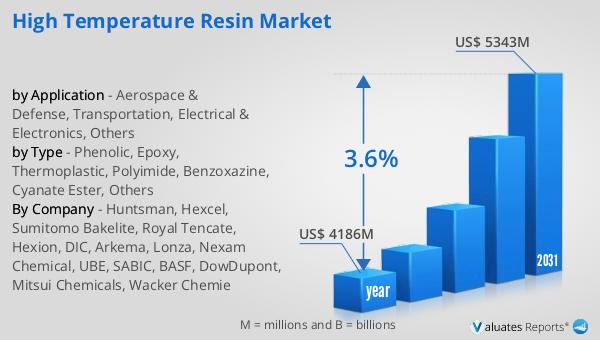

Global High Temperature Resin Market Outlook:

The market outlook for the Global High Temperature Resin Market indicates a positive trajectory, with the market's value standing at US$ 3806.6 million in 2023. This figure is projected to climb to US$ 5012.7 million by the year 2030, marking a compound annual growth rate (CAGR) of 3.6% throughout the forecast period spanning from 2024 to 2030. This growth reflects the increasing demand for materials capable of performing under extreme thermal conditions across various industries, including aerospace, automotive, electronics, and more. The expansion of the market is driven by the continuous advancements in material science and engineering, which are enabling the development of new high-temperature resin formulations with enhanced properties and performance. As industries continue to push the boundaries of technology and innovation, the need for resilient, high-temperature resistant materials becomes more pronounced, fueling the growth of the Global High Temperature Resin Market. This outlook underscores the market's vital role in supporting the evolution of industrial and technological capabilities worldwide.

| Report Metric | Details |

| Report Name | High Temperature Resin Market |

| Accounted market size in 2023 | US$ 3806.6 million |

| Forecasted market size in 2030 | US$ 5012.7 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Huntsman, Hexcel, Sumitomo Bakelite, Royal Tencate, Hexion, DIC, Arkema, Lonza, Nexam Chemical, UBE, SABIC, BASF, DowDupont, Mitsui Chemicals, Wacker Chemie |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |