What is Global Heat Resistance ASA Resin Market?

The Global Heat Resistance ASA Resin Market refers to the worldwide market for Acrylonitrile Styrene Acrylate (ASA) resins that are known for their exceptional resistance to heat, UV, and weathering, making them ideal for various applications where durability under extreme conditions is essential. This market encompasses the production, distribution, and sale of ASA resins, catering to industries that require materials with high thermal stability and resistance to outdoor exposure. As industries across the globe continue to innovate and seek materials that can withstand harsh environments, the demand for heat-resistant ASA resins has seen a significant uptick. These resins are particularly favored for their ability to maintain color and physical properties when exposed to sunlight and high temperatures, which is crucial for products used outdoors or in high-heat environments. The market's growth is propelled by the expanding applications of ASA resins in automotive components, construction materials, and consumer goods, among others. As technology advances and the push for more durable and long-lasting materials grows, the Global Heat Resistance ASA Resin Market is poised for further expansion, catering to a broader range of industries seeking to leverage the unique properties of these resins.

Blow Molding, Injection Molding in the Global Heat Resistance ASA Resin Market:

Blow Molding and Injection Molding are two pivotal processes in the Global Heat Resistance ASA Resin Market, each playing a crucial role in shaping the applications and utility of ASA resins across various industries. Blow molding is a manufacturing process used to create hollow objects made from thermoplastic materials, such as heat-resistant ASA resins. This process is particularly beneficial for producing parts with uniform wall thickness and is widely used in making containers, bottles, and other hollow shapes. The heat resistance of ASA resin makes it an ideal choice for products that need to withstand high temperatures or exposure to the sun without deforming. On the other hand, injection molding involves melting the ASA resin and injecting it into a mold to create a desired shape. This process is known for its precision and ability to produce complex and intricate designs, making it a preferred method for manufacturing automotive components, electronic housings, and other high-performance parts. The heat-resistant properties of ASA resin ensure that the final products are durable, stable, and capable of maintaining their integrity in harsh environments. Both blow molding and injection molding processes leverage the unique characteristics of ASA resins, such as their superior thermal stability, UV resistance, and aesthetic appeal, to meet the demanding requirements of various applications. As the Global Heat Resistance ASA Resin Market continues to evolve, these manufacturing processes remain integral to the development and production of innovative, high-quality products that cater to the needs of diverse industries.

Automotive, Home Appliances, High-end Consumer Electronics, Others in the Global Heat Resistance ASA Resin Market:

The usage of Global Heat Resistance ASA Resin in various areas such as Automotive, Home Appliances, High-end Consumer Electronics, and Others highlights the versatility and importance of this material in modern manufacturing and design. In the automotive sector, ASA resin is utilized for exterior parts such as grilles, mirror housings, and trim components, owing to its excellent weatherability and resistance to fading under UV exposure. This ensures that vehicles retain their aesthetic appeal over time, even when subjected to harsh environmental conditions. For home appliances, ASA resin's heat resistance makes it an ideal choice for components that are exposed to high temperatures, such as coffee machine parts and outdoor grill housings, providing durability and longevity. In the realm of high-end consumer electronics, ASA resin is used in the casings of devices for its superior finish, UV resistance, and the ability to withstand thermal stress, ensuring that devices not only look good but are also durable. Additionally, in other applications, ASA resin's properties are leveraged in outdoor furniture, sporting goods, and construction materials, where its resistance to weathering, UV, and heat are critical for the longevity and maintenance of the product's appearance and functionality. The widespread use of Global Heat Resistance ASA Resin across these diverse sectors underscores its value in delivering performance, durability, and aesthetic quality, catering to the evolving demands of consumers and industries alike.

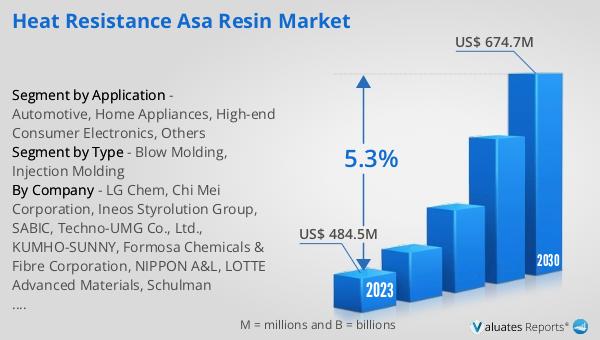

Global Heat Resistance ASA Resin Market Outlook:

The market outlook for the Global Heat Resistance ASA Resin Market reveals a promising trajectory, with the market's value estimated at US$ 484.5 million in 2023, and projections suggesting a growth to US$ 674.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. A significant insight into the market's competitive landscape is that approximately 70% of the market share is concentrated among the top five manufacturers globally. This concentration indicates a strong presence of leading players who dominate the market, reflecting the competitive and innovative nature of the industry. The anticipated growth in the market value underscores the increasing demand for heat-resistant ASA resins across various applications and industries. These resins are sought after for their exceptional qualities, including resistance to heat, UV, and weathering, making them indispensable in sectors that require materials capable of withstanding harsh environmental conditions. The market's expansion is a testament to the growing recognition of ASA resin's versatility and its critical role in enhancing the durability and performance of products in automotive, construction, consumer electronics, and other industries.

| Report Metric | Details |

| Report Name | Heat Resistance ASA Resin Market |

| Accounted market size in 2023 | US$ 484.5 million |

| Forecasted market size in 2030 | US$ 674.7 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LG Chem, Chi Mei Corporation, Ineos Styrolution Group, SABIC, Techno-UMG Co., Ltd., KUMHO-SUNNY, Formosa Chemicals & Fibre Corporation, NIPPON A&L, LOTTE Advanced Materials, Schulman (LyondellBasell), Romira, SAX Polymers Industries, Technoform, Run Feng Sci.&Tech, Shandong Novista Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |