What is Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market?

The Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market is a specialized sector that focuses on the production and distribution of high-precision gear reducers, specifically designed for use in industrial robots. These gear reducers are essential components that facilitate the smooth and accurate movement of robots, ensuring their operations are efficient and precise. The harmonic drive, a key feature of these gear reducers, is renowned for its ability to provide high reduction ratios, exceptional accuracy, and compact sizes, making it an ideal choice for robotics applications where space and weight are critical considerations. As industries continue to embrace automation and robotics, the demand for these specialized gear reducers has seen a significant uptick. This market's growth is driven by the increasing adoption of industrial robots across various sectors, including automotive, electronics, healthcare, and manufacturing, to enhance productivity, accuracy, and safety. The precision and reliability of harmonic drive gear reducers make them a pivotal component in the development and operation of industrial robots, positioning this market for continued expansion and innovation.

Cup Style, Hat Style, Pancake Style in the Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market:

Diving into the specifics of the Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market, we find it segmented into three distinct styles: Cup Style, Hat Style, and Pancake Style. Each style caters to different engineering and design needs within the realm of industrial robotics. The Cup Style is characterized by its deep, cup-like shape, offering a compact design that fits well into the limited spaces of many robots. This style is particularly favored for its high torque capacity and efficiency, making it suitable for robots requiring precise control and strength. On the other hand, the Hat Style, with its unique configuration, provides a balance between size and performance, making it a versatile option for a wide range of robotic applications. Its design allows for easy integration into robotic systems, where space is less constrained but where precision and reliability are still paramount. Lastly, the Pancake Style stands out for its flat, thin design, making it the go-to choice for applications where axial space is minimal. This style is engineered to offer high precision in a compact form factor, ideal for robots that operate in tight spaces or require a low profile. Each of these styles plays a crucial role in the broader market, catering to the diverse needs of industrial robots by providing tailored solutions that enhance performance, efficiency, and reliability.

Multi-joint Industrial Robots, SCARA Industrial Robots, Others in the Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market:

In the realm of industrial robotics, the Global Harmonic Drive Precision Gear Reducer finds its application across various types, notably in Multi-joint Industrial Robots, SCARA Industrial Robots, and others. Multi-joint industrial robots, which are known for their versatility and flexibility, benefit immensely from these precision gear reducers. They enable the robots to perform complex tasks with high accuracy and repeatability, making them indispensable in assembly lines, painting, and welding operations. The precision and compactness of the harmonic drive gear reducers align perfectly with the design requirements of SCARA (Selective Compliance Assembly Robot Arm) robots. These robots are primarily used for pick-and-place tasks, assembly operations, and precision machining. The gear reducers enhance the SCARA robots' speed and precision, allowing for faster cycle times and improved productivity. In other robotic applications, including those that may not fit neatly into the categories of multi-joint or SCARA robots, harmonic drive gear reducers offer the same benefits of precision, compactness, and reliability. Whether it's in custom-designed robots for specific tasks or in emerging robotic technologies, the adaptability and performance of these gear reducers make them a valuable component in the advancement and efficiency of industrial robotics. The widespread usage of these gear reducers across various types of industrial robots underscores their importance in the ongoing evolution and optimization of robotic automation.

Global Harmonic Drive Precision Gear Reducer for Industrial Robots Market Outlook:

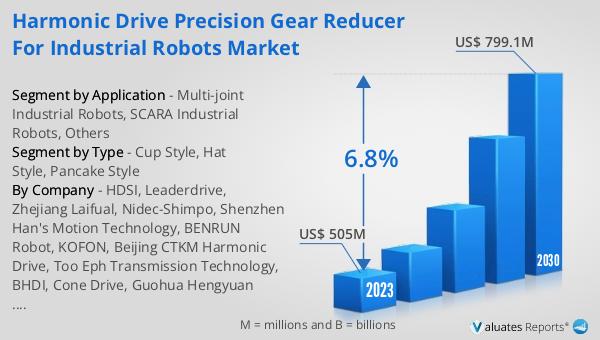

The market outlook for the Global Harmonic Drive Precision Gear Reducer for Industrial Robots presents a promising future. In 2023, the market's value stood at approximately 505 million USD. Looking ahead, projections suggest a growth trajectory that could see the market's worth escalate to around 799.1 million USD by the year 2030. This anticipated growth, marked by a compound annual growth rate (CAGR) of 6.8% over the forecast period from 2024 to 2030, underscores the increasing reliance on and demand for precision gear reducers in the field of industrial robotics. Such growth is indicative of the expanding role of automation and robotics across various industries, driven by the need for efficiency, precision, and reliability in production processes. As businesses continue to seek solutions that enhance productivity and reduce operational costs, the demand for high-quality, precision gear reducers is expected to rise, further propelling the market's expansion. This outlook not only highlights the market's potential for growth but also reflects the broader trend towards increased automation and the critical role of components like harmonic drive precision gear reducers in enabling this shift.

| Report Metric | Details |

| Report Name | Harmonic Drive Precision Gear Reducer for Industrial Robots Market |

| Accounted market size in 2023 | US$ 505 million |

| Forecasted market size in 2030 | US$ 799.1 million |

| CAGR | 6.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HDSI, Leaderdrive, Zhejiang Laifual, Nidec-Shimpo, Shenzhen Han's Motion Technology, BENRUN Robot, KOFON, Beijing CTKM Harmonic Drive, Too Eph Transmission Technology, BHDI, Cone Drive, Guohua Hengyuan Tech Dev Co., Ltd., LI-MING Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |