What is Global Four-High Aluminium Foil Rolling Mills Market?

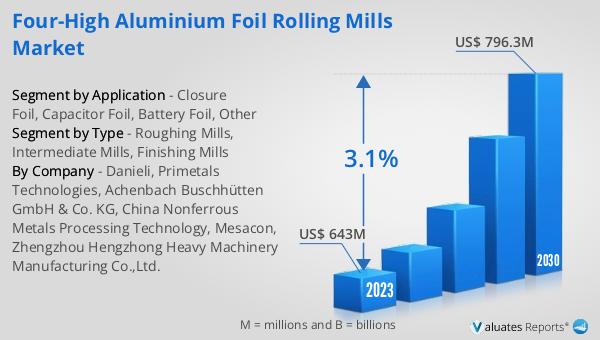

The Global Four-High Aluminium Foil Rolling Mills Market refers to a specialized sector within the broader aluminium industry, focusing on the production of aluminium foil through a specific type of rolling mill known as a four-high rolling mill. This kind of mill is characterized by using two large backup rolls and two smaller work rolls to achieve the desired thickness and surface quality of the aluminium foil. The process is highly efficient and allows for the production of aluminium foil in various thicknesses and for different applications, ranging from packaging materials to electrical components. The market for these mills is driven by the demand for high-quality aluminium foil in various industries, including food and beverage, pharmaceuticals, and electronics, among others. As of 2023, the market has been valued at US$ 643 million, with projections suggesting growth to US$ 796.3 million by 2030, indicating a steady increase in demand for these specialized rolling mills. This growth is attributed to the expanding applications of aluminium foil and the need for more efficient and precise production methods offered by four-high rolling mills.

Roughing Mills, Intermediate Mills, Finishing Mills in the Global Four-High Aluminium Foil Rolling Mills Market:

In the realm of the Global Four-High Aluminium Foil Rolling Mills Market, the process of transforming aluminium ingots into thin, high-quality foil involves several stages, each carried out by a specific type of mill: roughing mills, intermediate mills, and finishing mills. Roughing mills are the first step in the process, where the ingot is passed through the mill to reduce its thickness substantially. This stage is crucial for breaking down the ingot into a manageable size for further refinement. Following this, the aluminium strip is passed through intermediate mills, which continue the process of thickness reduction but with greater precision. The material's thickness is methodically decreased, and its surface is smoothed to prepare it for the final stage. Finishing mills represent the culmination of the rolling process, where the aluminium reaches its final thickness and surface quality. These mills are highly specialized, ensuring that the foil meets the stringent specifications required for its various applications. The precision and efficiency of these mills are paramount, as they directly impact the quality and usability of the final product. The entire process showcases the technological advancements and engineering expertise inherent in the Global Four-High Aluminium Foil Rolling Mills Market, highlighting its critical role in meeting the global demand for high-quality aluminium foil.

Closure Foil, Capacitor Foil, Battery Foil, Other in the Global Four-High Aluminium Foil Rolling Mills Market:

The Global Four-High Aluminium Foil Rolling Mills Market plays a pivotal role in producing aluminium foil for various applications, significantly impacting industries such as packaging, electronics, and energy. Closure foil, for instance, is a prime application, where the foil's superior barrier properties are utilized to seal off products, ensuring freshness and preventing contamination. This application is widespread in the food and beverage industry, where maintaining product integrity is paramount. Capacitor foil is another critical application, serving the electronics industry. Here, the foil is used in the manufacture of electrical components, where its ability to conduct electricity and withstand high temperatures makes it indispensable. Similarly, battery foil is a rapidly growing segment, driven by the surge in demand for lithium-ion batteries. The foil is used as both the cathode and anode in batteries, its high conductivity and lightweight nature making it ideal for this purpose. Other applications include pharmaceutical packaging, where the foil's barrier properties are leveraged to protect medications from moisture and contaminants, and insulation materials, where its reflective surface helps in thermal management. Each of these applications underscores the versatility and essential nature of aluminium foil produced by four-high rolling mills, highlighting the market's significance across multiple sectors.

Global Four-High Aluminium Foil Rolling Mills Market Outlook:

Regarding the market outlook for the Global Four-High Aluminium Foil Rolling Mills Market, it's observed that the sector started with a valuation of US$ 643 million in 2023. Looking ahead, it's expected to experience a growth trajectory, reaching a valuation of US$ 796.3 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 3.1% throughout the forecast period spanning from 2024 to 2030. This projection underscores a positive and steady demand for aluminium foil rolling mills, which are essential in producing high-quality aluminium foil for various applications. The anticipated growth is reflective of the increasing applications of aluminium foil across different industries, including but not limited to, food and beverage packaging, pharmaceuticals, electronics, and energy. The market's expansion is indicative of the broader trends in these sectors, where the properties of aluminium foil, such as its lightweight, non-toxic nature, and excellent barrier qualities, are increasingly valued. This outlook suggests a robust future for the Global Four-High Aluminium Foil Rolling Mills Market, driven by ongoing technological advancements and growing market demands.

| Report Metric | Details |

| Report Name | Four-High Aluminium Foil Rolling Mills Market |

| Accounted market size in 2023 | US$ 643 million |

| Forecasted market size in 2030 | US$ 796.3 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Danieli, Primetals Technologies, Achenbach Buschhütten GmbH & Co. KG, China Nonferrous Metals Processing Technology, Mesacon, Zhengzhou Hengzhong Heavy Machinery Manufacturing Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |