What is Global Flange Protector Band Market?

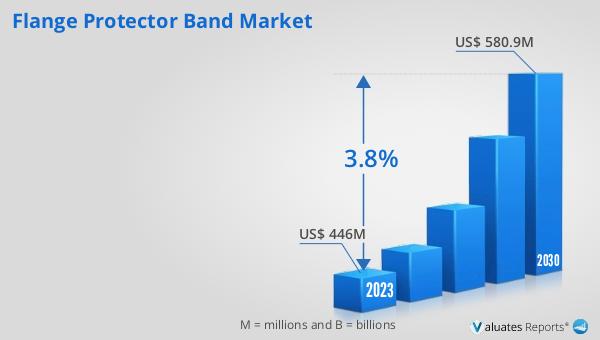

The Global Flange Protector Band Market is a niche yet significant segment within the broader industrial protective equipment sector, focusing on safeguarding flange faces, edges, and surfaces from damage during storage, transit, or installation. These bands are crucial for maintaining the integrity of flange connections, which are pivotal in various piping and machinery applications across industries. Essentially, flange protector bands are designed to prevent corrosion, ingress of foreign materials, and physical damages that can compromise the sealing capability of flanged joints. Given the critical nature of many flanged connections in oil and gas, chemical processing, and water treatment facilities, among others, the demand for reliable and effective flange protection solutions is substantial. The market's value, pegged at US$ 446 million in 2023, underscores the importance of these protective bands in industrial operations. With projections suggesting a growth to US$ 580.9 million by 2030, at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2030, it's clear that the sector is on an upward trajectory. This growth is driven by the expanding industrial sector globally, increased focus on maintenance and safety standards, and the ongoing development of more durable and innovative flange protection products.

in the Global Flange Protector Band Market:

In the realm of the Global Flange Protector Band Market, a diverse array of types caters to the varied needs and specifications of customers. These protector bands are not one-size-fits-all; instead, they are meticulously designed to meet the unique requirements of different flange sizes, materials, and environmental conditions they will be exposed to. From simple nylon and polyethylene bands that offer basic protection against dust and moisture, to more sophisticated stainless steel and alloy bands designed for extreme conditions and temperatures, the range is extensive. Some bands are equipped with quick-locking mechanisms for ease of installation, while others might feature UV-resistant materials for outdoor applications. There are also environmentally friendly options made from recyclable materials for industries focusing on sustainability. The choice of a flange protector band depends on several factors, including the type of fluid being transported through the flanges, the external environment (whether it's corrosive, prone to extreme temperatures, or has high UV exposure), and the regulatory standards the industry must comply with. For instance, the oil and gas industry, known for its harsh operating conditions, requires highly durable and corrosion-resistant bands, whereas the pharmaceutical sector might prioritize sanitary and non-contaminant materials. This variety ensures that every sector can find a suitable flange protector band that meets its specific needs, thereby safeguarding their operations and extending the lifespan of their flanged connections.

in the Global Flange Protector Band Market:

Flange protector bands find their applications in a wide array of industries, serving a fundamental purpose: to protect and maintain the integrity of flange connections. These bands are indispensable in sectors where piping systems play a critical role, such as oil and gas, chemical manufacturing, water treatment, and pharmaceuticals. In the oil and gas industry, for example, flange protector bands are used to prevent the ingress of contaminants and corrosion, which can lead to costly downtimes and safety hazards. Similarly, in the chemical manufacturing sector, these bands protect flanges from aggressive chemicals and environmental conditions, ensuring that processes run smoothly without leaks or contamination. Water treatment facilities rely on them to prevent the entry of debris and other foreign materials that could compromise the water quality and system efficiency. In the pharmaceutical industry, where cleanliness and contamination control are paramount, flange protector bands play a crucial role in maintaining sterile environments. Beyond these, the power generation, food and beverage, and marine industries also benefit from the use of flange protector bands, highlighting their versatility and essential role in modern industrial operations. The broad spectrum of applications underscores the importance of these protective bands in ensuring the safety, reliability, and longevity of flanged connections across various sectors.

Global Flange Protector Band Market Outlook:

The market outlook for the Global Flange Protector Band sector presents a promising future, with its valuation set at US$ 446 million as of 2023. This figure is expected to climb to US$ 580.9 million by the year 2030, marking a steady compound annual growth rate (CAGR) of 3.8% throughout the forecast period spanning from 2024 to 2030. This anticipated growth trajectory underscores the increasing recognition of the critical role that flange protector bands play in a wide range of industrial applications. As industries worldwide continue to expand and evolve, the demand for these protective bands is set to rise, driven by the need to safeguard flange connections against damage, corrosion, and contamination. This growth is also reflective of the ongoing advancements in flange protector technologies and materials, aimed at offering more durable, efficient, and cost-effective solutions for industrial protection needs. The market's expansion is indicative of the broader trends in industrial safety and maintenance, where the emphasis on preventing downtime and ensuring operational integrity is more pronounced than ever.

| Report Metric | Details |

| Report Name | Flange Protector Band Market |

| Accounted market size in 2023 | US$ 446 million |

| Forecasted market size in 2030 | US$ 580.9 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |