What is Global CMP Pads Conditioning Disk Market?

The Global CMP Pads Conditioning Disk Market is a specialized segment within the semiconductor manufacturing industry, focusing on the production and distribution of conditioning disks used in Chemical Mechanical Planarization (CMP). CMP is a critical process in semiconductor fabrication, where surfaces of wafers are smoothed and flattened through mechanical and chemical means to prepare them for subsequent layers of circuitry. Conditioning disks play a vital role in this process, ensuring that the CMP pads are kept in optimal condition for effective planarization. These disks help in maintaining the pad’s texture and flatness, crucial for achieving the desired wafer surface quality. As the semiconductor industry continues to advance, with chips becoming ever more complex and miniaturized, the demand for high-quality CMP conditioning disks is expected to grow. This market's dynamics are influenced by technological advancements, the scaling of wafer sizes, and the increasing complexity of semiconductor devices. The focus on enhancing the efficiency and longevity of CMP pads through innovative conditioning disks underscores the market's importance in supporting the broader trends of the semiconductor manufacturing sector.

Conventional Pad Conditioners, CVD Diamond Pad Conditioners in the Global CMP Pads Conditioning Disk Market:

In the realm of the Global CMP Pads Conditioning Disk Market, two primary types of pad conditioners stand out: Conventional Pad Conditioners and CVD Diamond Pad Conditioners. Conventional Pad Conditioners, often made from silicon carbide or other abrasive materials, have been the industry standard for many years. These conditioners work by mechanically abrading the pad surface to maintain its roughness and effectiveness in the CMP process. They are known for their cost-effectiveness and are widely used across various semiconductor manufacturing stages. However, as the industry moves towards more complex and delicate wafer designs, the demand for conditioners that can offer precise and consistent conditioning has led to the rise of CVD Diamond Pad Conditioners. CVD (Chemical Vapor Deposition) Diamond Pad Conditioners utilize diamond particles, one of the hardest materials available, to provide a superior conditioning performance. These diamonds are deposited on the disk substrate through a chemical vapor deposition process, resulting in a highly durable and efficient conditioning tool. CVD Diamond Pad Conditioners are praised for their longevity and the ability to maintain consistent pad conditions over time, making them increasingly popular for advanced semiconductor manufacturing processes. The shift towards CVD Diamond technology reflects the industry's need for high-precision and high-quality conditioning solutions to meet the evolving demands of semiconductor fabrication.

300 mm Wafer, 200 mm Wafer, Others in the Global CMP Pads Conditioning Disk Market:

The Global CMP Pads Conditioning Disk Market finds its application across various wafer sizes, notably in the 300 mm, 200 mm, and other categories. The 300 mm wafer segment represents the forefront of semiconductor manufacturing, where the demand for conditioning disks is driven by the need for high-volume, high-efficiency production lines. In this segment, conditioning disks are crucial for maintaining the quality and consistency of CMP pads, directly impacting the yield and performance of semiconductor devices. The precision required for conditioning at this scale underscores the importance of advanced conditioner technologies, such as CVD Diamond Pad Conditioners, which offer the durability and consistency needed for large-scale production. On the other hand, the 200 mm wafer segment, while gradually being phased out in favor of larger diameters, still holds significant demand in certain markets and applications. Conditioning disks for this segment are tailored to meet the specific requirements of legacy production lines, balancing cost and performance for optimal efficiency. Additionally, the 'Others' category encompasses emerging and niche applications, including smaller wafer sizes and specialized semiconductor manufacturing processes. This diversity in application areas highlights the versatility and adaptability of conditioning disk technologies to meet a wide range of manufacturing needs, reflecting the dynamic nature of the semiconductor industry.

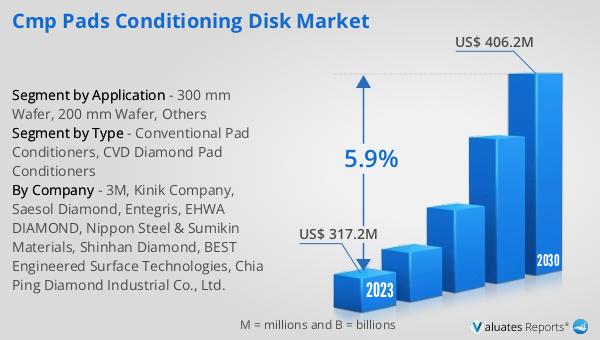

Global CMP Pads Conditioning Disk Market Outlook:

The Global CMP Pads Conditioning Disk Market's outlook presents a promising future, with its valuation set at US$ 317.2 million in 2023, and projections indicating a growth to US$ 406.2 million by 2030. This anticipated expansion, at a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030, underscores the increasing demand and significance of CMP conditioning disks in the semiconductor manufacturing industry. The market is currently dominated by first-tier manufacturers such as 3M, Kinik Company, Saesol, Diamond, and Entegris, which collectively accounted for approximately 82.15% of the market share. This concentration of market share among the top players highlights their pivotal role in driving innovation and setting quality standards within the industry. Meanwhile, second-tier manufacturers like EHWA DIAMOND, Nippon Steel & Sumikin Materials, and Shinhan Diamond also contribute to the market's diversity and competitiveness. The distribution of market share between these tiers reflects a dynamic and evolving market landscape, where both established and emerging players play crucial roles in meeting the diverse needs of semiconductor manufacturers worldwide. This market outlook not only showcases the current state of the CMP Pads Conditioning Disk Market but also highlights its critical role in supporting the continuous advancement and scaling of semiconductor technology.

| Report Metric | Details |

| Report Name | CMP Pads Conditioning Disk Market |

| Accounted market size in 2023 | US$ 317.2 million |

| Forecasted market size in 2030 | US$ 406.2 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Kinik Company, Saesol Diamond, Entegris, EHWA DIAMOND, Nippon Steel & Sumikin Materials, Shinhan Diamond, BEST Engineered Surface Technologies, Chia Ping Diamond Industrial Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |