What is Global Automotive Metal Forming Market?

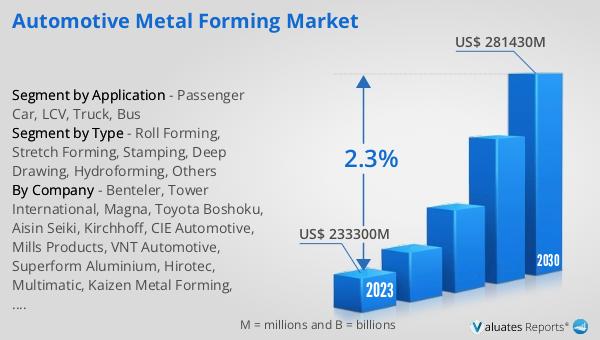

The Global Automotive Metal Forming Market is a specialized sector within the broader automotive industry, focusing on the transformation of metal into various components and structures used in vehicles. This market encompasses a range of techniques and processes designed to shape and mold metal materials to meet the precise requirements of automotive manufacturing. At its core, metal forming involves altering the form of metal sheets or blanks into specific shapes through mechanical or hydraulic forces, without removing any material. This sector is crucial for producing a wide array of automotive parts, from the structural elements of the car body to intricate engine components. As of 2023, the market has been valued at US$ 233,300 million, showcasing its significant role in the automotive industry's supply chain. With an expected growth to reach US$ 281,430 million by 2030, the Global Automotive Metal Forming Market is on a trajectory of steady expansion, driven by advancements in technology, increasing demand for vehicles, and the continuous evolution of automotive design and manufacturing techniques. This growth reflects the industry's adaptation to changing automotive trends, including the shift towards more fuel-efficient and environmentally friendly vehicles, which often require innovative metal forming solutions.

Roll Forming, Stretch Forming, Stamping, Deep Drawing, Hydroforming, Others in the Global Automotive Metal Forming Market:

In the realm of the Global Automotive Metal Forming Market, various techniques such as Roll Forming, Stretch Forming, Stamping, Deep Drawing, Hydroforming, and others play pivotal roles. Roll Forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through sets of rolls mounted on consecutive stands, each performing an incremental part of the bend until the desired cross-section profile is obtained. This method is highly efficient for producing consistent, complex cross-sectional profiles. Stretch Forming, on the other hand, involves stretching a metal sheet or plate over a form or die until the desired shape is achieved, commonly used for large, smooth parts with gentle curves. Stamping, a cornerstone technique in the automotive industry, involves placing flat metal sheets into a stamping press where tool and die surfaces form the metal into shape. This process is essential for creating high precision parts at high volumes. Deep Drawing, a form of metal stamping, is used to create deep, hollow shapes by drawing a sheet metal blank into a forming die with a punch. This method is ideal for components like automotive bodies and fuel tanks. Hydroforming, a relatively newer technique, uses high-pressure hydraulic fluid to press metal into a die, allowing for more complex shapes and stronger, lighter parts. Each of these techniques has its unique advantages and applications within the automotive sector, contributing to the versatility and innovation in vehicle manufacturing and design.

Passenger Car, LCV, Truck, Bus in the Global Automotive Metal Forming Market:

The Global Automotive Metal Forming Market finds its applications spread across various vehicle types, including Passenger Cars, Light Commercial Vehicles (LCV), Trucks, and Buses. In Passenger Cars, metal forming techniques are extensively used to create body panels, frames, and other structural components that contribute to the vehicle's overall safety, aesthetics, and performance. The precision and efficiency of metal forming processes allow for the production of lightweight, high-strength parts that can enhance fuel efficiency and reduce emissions. For LCVs, the demand for durable and robust components is paramount, given their utility in transporting goods and services. Metal forming provides the necessary strength and flexibility in manufacturing parts that can withstand the rigors of commercial use while maintaining the vehicle's integrity. Trucks, which are critical to the logistics and transportation industry, rely heavily on metal formed parts for their chassis, bodywork, and engine components. The strength-to-weight ratio achieved through advanced metal forming techniques ensures that trucks can carry heavy loads efficiently while meeting stringent safety standards. Buses also benefit from metal forming in creating large, structural components that are essential for passenger safety and comfort. The application of metal forming in these vehicle segments underscores its importance in producing reliable, high-quality automotive parts that meet the diverse needs of the global automotive market.

Global Automotive Metal Forming Market Outlook:

The market outlook for the Global Automotive Metal Forming Market presents a promising future, with its valuation at US$ 233,300 million in 2023, and an expected rise to US$ 281,430 million by 2030. This projection indicates a Compound Annual Growth Rate (CAGR) of 2.3% over the forecast period from 2024 to 2030. Such growth underscores the market's resilience and its capacity to adapt to the evolving demands of the automotive industry. The increase in market value can be attributed to several factors, including technological advancements in metal forming processes, the growing automotive production globally, and the rising demand for lightweight, high-strength metal components that contribute to vehicle efficiency and sustainability. This outlook reflects the industry's ongoing efforts to innovate and improve manufacturing techniques, which in turn supports the broader goals of reducing environmental impact and enhancing vehicle performance. The anticipated growth of the Global Automotive Metal Forming Market is a testament to its critical role in shaping the future of automotive manufacturing, highlighting its contribution to the development of safer, more efficient, and environmentally friendly vehicles.

| Report Metric | Details |

| Report Name | Automotive Metal Forming Market |

| Accounted market size in 2023 | US$ 233300 million |

| Forecasted market size in 2030 | US$ 281430 million |

| CAGR | 2.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Benteler, Tower International, Magna, Toyota Boshoku, Aisin Seiki, Kirchhoff, CIE Automotive, Mills Products, VNT Automotive, Superform Aluminium, Hirotec, Multimatic, Kaizen Metal Forming, Quintus Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |