What is Global Peristaltic Filling Machine Market?

The Global Peristaltic Filling Machine Market refers to the worldwide industry focused on the production and distribution of peristaltic filling machines. These machines are specialized equipment used for filling liquids into containers, utilizing a peristaltic pump mechanism. This mechanism involves the compression and relaxation of a flexible tube, which helps in moving the liquid through the tube and into the container. The market for these machines is driven by their ability to handle a wide range of liquid viscosities and their suitability for sterile and contamination-free filling processes. Industries such as pharmaceuticals, food and beverages, cosmetics, and chemicals are major consumers of peristaltic filling machines due to their precision and efficiency. The market is characterized by technological advancements, increasing demand for automation, and the need for high-quality packaging solutions. As industries continue to prioritize hygiene and precision in their operations, the demand for peristaltic filling machines is expected to grow, making this market a significant segment within the broader packaging machinery industry.

Fully Automatic, Semi-automatic in the Global Peristaltic Filling Machine Market:

In the Global Peristaltic Filling Machine Market, machines are categorized based on their level of automation: fully automatic and semi-automatic. Fully automatic peristaltic filling machines are designed to perform the entire filling process with minimal human intervention. These machines are equipped with advanced sensors and control systems that ensure precise filling, capping, and labeling of containers. They are ideal for high-volume production environments where speed and accuracy are crucial. The fully automatic machines are often integrated into larger production lines, allowing for seamless operation and increased efficiency. They are particularly popular in industries such as pharmaceuticals and food and beverages, where maintaining product integrity and hygiene is paramount. On the other hand, semi-automatic peristaltic filling machines require some level of human involvement in the filling process. While they automate certain aspects, such as the pumping and dispensing of liquids, operators are needed to manually place containers and initiate the filling cycle. These machines are suitable for small to medium-sized production runs and offer flexibility in handling different container sizes and shapes. Semi-automatic machines are often favored by smaller businesses or those with diverse product lines, as they provide a cost-effective solution without compromising on quality. Both fully automatic and semi-automatic machines offer distinct advantages, and the choice between them depends on factors such as production volume, budget, and specific industry requirements. As technology continues to evolve, the Global Peristaltic Filling Machine Market is witnessing innovations that enhance the capabilities of both types of machines, making them more efficient, user-friendly, and adaptable to changing industry needs.

Food and Drinks, The Medical, Cosmetic, Other in the Global Peristaltic Filling Machine Market:

The Global Peristaltic Filling Machine Market finds extensive usage across various sectors, including food and drinks, medical, cosmetic, and other industries. In the food and drinks sector, peristaltic filling machines are employed for their ability to handle a wide range of liquid viscosities, from thin beverages to thick sauces. These machines ensure precise filling, reducing product wastage and maintaining consistency in packaging. The hygienic nature of peristaltic pumps makes them ideal for food and beverage applications, as they prevent contamination and preserve the quality of the products. In the medical field, peristaltic filling machines are crucial for filling sterile liquids, such as pharmaceuticals, vaccines, and diagnostic reagents. The machines' ability to maintain a sterile environment during the filling process is essential for ensuring the safety and efficacy of medical products. In the cosmetic industry, these machines are used for filling creams, lotions, and other personal care products. The precision and flexibility of peristaltic filling machines allow for accurate filling of various container sizes and shapes, catering to the diverse packaging needs of cosmetic manufacturers. Additionally, other industries, such as chemicals and biotechnology, benefit from the use of peristaltic filling machines for their ability to handle corrosive and sensitive liquids. The versatility and reliability of peristaltic filling machines make them a valuable asset across multiple sectors, driving their demand in the global market.

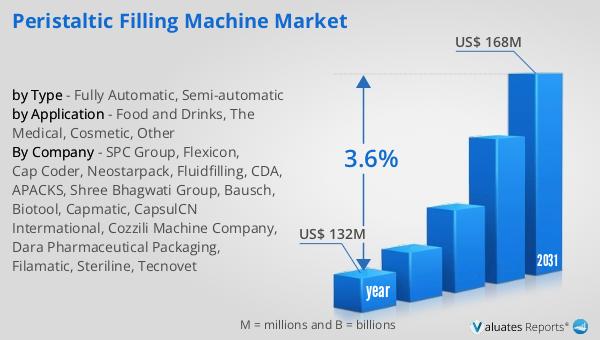

Global Peristaltic Filling Machine Market Outlook:

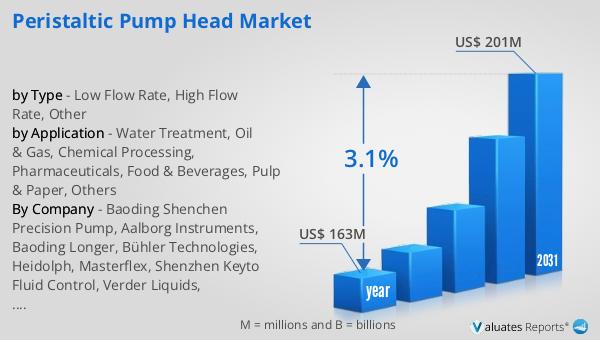

The global market for peristaltic filling machines was valued at approximately $132 million in 2024. This market is anticipated to grow steadily, reaching an estimated value of $168 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.6% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for automation in various industries, the need for precise and contamination-free filling processes, and the growing emphasis on maintaining product quality and hygiene. As industries continue to evolve and prioritize efficiency and accuracy in their operations, the demand for peristaltic filling machines is expected to rise. The market's growth is also supported by technological advancements that enhance the capabilities of these machines, making them more efficient and adaptable to changing industry needs. The increasing adoption of peristaltic filling machines across sectors such as pharmaceuticals, food and beverages, cosmetics, and chemicals further contributes to the market's expansion. As a result, the global peristaltic filling machine market is poised for steady growth, driven by the ongoing demand for high-quality packaging solutions and the continuous evolution of technology in the industry.

| Report Metric | Details |

| Report Name | Peristaltic Filling Machine Market |

| Accounted market size in year | US$ 132 million |

| Forecasted market size in 2031 | US$ 168 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SPC Group, Flexicon, Cap Coder, Neostarpack, Fluidfilling, CDA, APACKS, Shree Bhagwati Group, Bausch, Biotool, Capmatic, CapsulCN Intermational, Cozzili Machine Company, Dara Pharmaceutical Packaging, Filamatic, Steriline, Tecnovet |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |