What is Global FBE Coatings Market?

The Global Fusion Bonded Epoxy (FBE) Coatings Market is a specialized segment within the broader coatings industry, focusing on the application of epoxy-based coatings that are thermally bonded to various substrates. These coatings are primarily used to protect pipelines and other infrastructure from corrosion and wear. FBE coatings are known for their excellent adhesion properties, chemical resistance, and durability, making them ideal for use in harsh environments. The market for FBE coatings is driven by the increasing demand for corrosion-resistant materials in industries such as oil and gas, construction, and water treatment. The global market for FBE coatings is characterized by a diverse range of products and applications, catering to different industrial needs and specifications. The market is also influenced by regulatory standards and environmental considerations, which necessitate the use of high-performance coatings to ensure long-term protection and sustainability. As industries continue to expand and infrastructure projects grow in scale, the demand for FBE coatings is expected to rise, further driving innovation and development within this market segment.

Internal Coatings, External Coatings in the Global FBE Coatings Market:

Internal coatings and external coatings are two primary categories within the Global FBE Coatings Market, each serving distinct purposes and applications. Internal coatings are applied to the inner surfaces of pipelines and other infrastructure to prevent corrosion and improve flow efficiency. These coatings are crucial in industries such as oil and gas, where the transported materials can be highly corrosive. Internal FBE coatings provide a smooth, durable barrier that protects the pipeline from the inside, reducing maintenance costs and extending the lifespan of the infrastructure. On the other hand, external coatings are applied to the outer surfaces of pipelines and other structures to protect them from external environmental factors such as moisture, soil, and temperature fluctuations. External FBE coatings are designed to withstand harsh conditions and provide long-lasting protection against corrosion and mechanical damage. These coatings are essential for pipelines that are buried underground or exposed to the elements, as they prevent degradation and ensure the structural integrity of the infrastructure. Both internal and external FBE coatings are formulated to meet specific industry standards and performance requirements, ensuring that they provide reliable protection in various applications. The choice between internal and external coatings depends on the specific needs of the project and the environmental conditions in which the infrastructure will operate. In many cases, both types of coatings are used in conjunction to provide comprehensive protection for pipelines and other structures. The development and application of FBE coatings involve advanced technologies and processes to ensure optimal performance and durability. Manufacturers continuously invest in research and development to improve the properties of FBE coatings, such as adhesion, flexibility, and resistance to chemicals and abrasion. This ongoing innovation is crucial to meet the evolving demands of industries and to address the challenges posed by increasingly complex and demanding environments. The Global FBE Coatings Market is also influenced by regulatory standards and environmental considerations, which drive the adoption of high-performance coatings that minimize environmental impact and enhance sustainability. As industries continue to expand and infrastructure projects grow in scale, the demand for both internal and external FBE coatings is expected to rise, further driving innovation and development within this market segment.

Oil & Gas, Construction, Sewage & Wastewater Treatment, Refineries & Chemical, Water Transportation, Others in the Global FBE Coatings Market:

The Global FBE Coatings Market finds extensive usage across various industries, including oil and gas, construction, sewage and wastewater treatment, refineries and chemical, water transportation, and others. In the oil and gas industry, FBE coatings are primarily used to protect pipelines from corrosion and mechanical damage. These coatings provide a durable barrier that prevents the corrosive effects of transported materials, ensuring the longevity and reliability of the pipeline infrastructure. In the construction industry, FBE coatings are used to protect steel structures, reinforcing bars, and other metal components from corrosion and environmental degradation. These coatings enhance the durability and lifespan of construction materials, reducing maintenance costs and improving overall structural integrity. In sewage and wastewater treatment facilities, FBE coatings are applied to pipelines, tanks, and other infrastructure to prevent corrosion caused by harsh chemicals and biological agents. These coatings ensure the safe and efficient operation of treatment facilities, minimizing the risk of leaks and contamination. In refineries and chemical plants, FBE coatings are used to protect equipment and pipelines from the corrosive effects of chemicals and high temperatures. These coatings provide a reliable barrier that enhances the safety and efficiency of refinery operations. In water transportation systems, FBE coatings are applied to pipelines and other infrastructure to prevent corrosion and ensure the safe and efficient transport of water. These coatings are essential for maintaining the integrity of water supply systems and preventing leaks and contamination. Other industries that utilize FBE coatings include power generation, marine, and automotive, where the coatings provide protection against corrosion and wear in various applications. The versatility and durability of FBE coatings make them a preferred choice for a wide range of industrial applications, driving their demand in the global market.

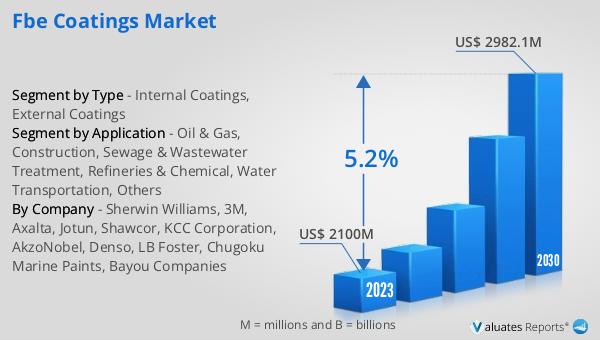

Global FBE Coatings Market Outlook:

The global FBE Coatings market was valued at US$ 2100 million in 2023 and is anticipated to reach US$ 2982.1 million by 2030, witnessing a CAGR of 5.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for corrosion-resistant coatings in various industries, including oil and gas, construction, and water treatment. The market is characterized by a diverse range of products and applications, catering to different industrial needs and specifications. The adoption of FBE coatings is also influenced by regulatory standards and environmental considerations, which necessitate the use of high-performance coatings to ensure long-term protection and sustainability. As industries continue to expand and infrastructure projects grow in scale, the demand for FBE coatings is expected to rise, further driving innovation and development within this market segment. The market outlook for FBE coatings is positive, with significant growth opportunities anticipated in the coming years.

| Report Metric | Details |

| Report Name | FBE Coatings Market |

| Accounted market size in 2023 | US$ 2100 million |

| Forecasted market size in 2030 | US$ 2982.1 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sherwin Williams, 3M, Axalta, Jotun, Shawcor, KCC Corporation, AkzoNobel, Denso, LB Foster, Chugoku Marine Paints, Bayou Companies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |