What is Global Nitrile Butadiene Rubber Seals Market?

The Global Nitrile Butadiene Rubber (NBR) Seals Market is a specialized segment within the broader rubber industry, focusing on the production and application of seals made from nitrile butadiene rubber. NBR is a synthetic rubber known for its excellent resistance to oils, fuels, and other chemicals, making it a preferred material for seals in various industries. These seals are used to prevent leakage and ensure the integrity of mechanical systems, ranging from automotive engines to industrial machinery. The market for NBR seals is driven by the demand for durable and reliable sealing solutions in sectors such as automotive, aerospace, oil and gas, and healthcare. The global reach of this market indicates its critical role in maintaining the functionality and safety of numerous applications worldwide. As industries continue to evolve and require more advanced sealing technologies, the NBR seals market is expected to grow, driven by innovations in material science and manufacturing processes.

BS2751 Grade, Food Contact Grade, Economy/Commercial Grade, Others in the Global Nitrile Butadiene Rubber Seals Market:

BS2751 Grade, Food Contact Grade, Economy/Commercial Grade, and other classifications within the Global Nitrile Butadiene Rubber Seals Market cater to specific needs and applications. BS2751 Grade refers to a British Standard specification for NBR seals, ensuring high-quality performance in demanding environments. These seals are typically used in applications requiring excellent resistance to oils, fuels, and other chemicals, making them ideal for automotive and industrial machinery. Food Contact Grade NBR seals are specially formulated to meet stringent safety and hygiene standards for use in food processing and packaging industries. These seals are designed to withstand exposure to food products and cleaning agents without compromising their integrity or contaminating the food. Economy/Commercial Grade NBR seals offer a cost-effective solution for less demanding applications where extreme chemical resistance and durability are not as critical. These seals are commonly used in general-purpose sealing applications, providing a balance between performance and affordability. Other classifications within the NBR seals market include specialized grades designed for specific industries or applications, such as medical-grade NBR seals for healthcare equipment or high-temperature NBR seals for use in extreme environments. Each grade of NBR seal is engineered to meet the unique requirements of its intended application, ensuring optimal performance and reliability. The diversity of NBR seal grades highlights the versatility of nitrile butadiene rubber as a sealing material, capable of meeting the needs of a wide range of industries and applications. As the demand for specialized sealing solutions continues to grow, the development of new NBR seal grades and formulations will play a crucial role in addressing emerging challenges and opportunities in the global market.

Aerospace and Defense, Infrastructure, Medical and Health Care, Oil Industry, Automotive, Others in the Global Nitrile Butadiene Rubber Seals Market:

The usage of Global Nitrile Butadiene Rubber Seals Market spans across various critical sectors, including Aerospace and Defense, Infrastructure, Medical and Health Care, Oil Industry, Automotive, and others. In the Aerospace and Defense sector, NBR seals are essential for ensuring the reliability and safety of aircraft and defense equipment. These seals are used in hydraulic systems, fuel systems, and other critical components, where their resistance to oils and fuels is paramount. In the Infrastructure sector, NBR seals are used in construction machinery, water treatment plants, and other infrastructure projects, providing reliable sealing solutions that withstand harsh environmental conditions. The Medical and Health Care sector relies on NBR seals for medical devices, diagnostic equipment, and pharmaceutical processing, where their chemical resistance and durability are crucial for maintaining sterility and functionality. In the Oil Industry, NBR seals are used in drilling equipment, pipelines, and refineries, where their ability to resist oils, fuels, and harsh chemicals ensures the integrity and safety of operations. The Automotive sector is one of the largest consumers of NBR seals, using them in engines, transmissions, and other critical components to prevent leaks and ensure optimal performance. Other sectors that utilize NBR seals include the manufacturing industry, where they are used in various machinery and equipment, and the consumer goods industry, where they are used in products such as appliances and electronics. The widespread use of NBR seals across these diverse sectors underscores their importance in maintaining the functionality and safety of a wide range of applications. As industries continue to evolve and face new challenges, the demand for high-quality NBR seals is expected to grow, driven by the need for reliable and durable sealing solutions.

Global Nitrile Butadiene Rubber Seals Market Outlook:

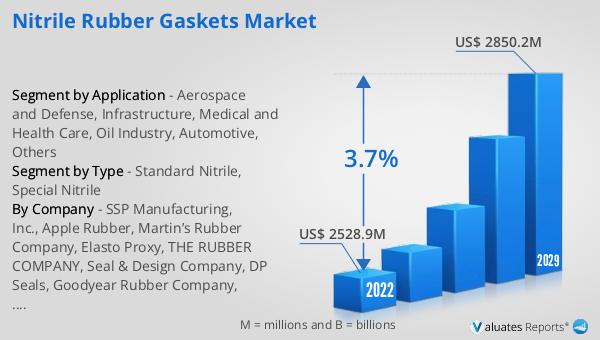

The Global Nitrile Butadiene Rubber (NBR) market is anticipated to grow from US$ 2528.9 million in 2022 to US$ 2850.2 million by 2029, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period from 2023 to 2029. China stands out as the largest market, accounting for approximately 37% of the global share, followed by Southeast Asia and Europe, which hold shares of about 16% and 15%, respectively. This growth trajectory highlights the increasing demand for NBR seals across various industries and regions. The robust market presence in China can be attributed to the country's expansive industrial base and growing automotive sector, which are significant consumers of NBR seals. Similarly, the markets in Southeast Asia and Europe are driven by the need for advanced sealing solutions in industries such as automotive, aerospace, and healthcare. The steady growth in these regions underscores the critical role of NBR seals in ensuring the reliability and efficiency of mechanical systems. As the global economy continues to recover and industrial activities pick up pace, the demand for high-quality NBR seals is expected to rise, further propelling the market's growth.

| Report Metric | Details |

| Report Name | Nitrile Butadiene Rubber Seals Market |

| Accounted market size in 2022 | US$ 2528.9 million |

| Forecasted market size in 2029 | US$ 2850.2 million |

| CAGR | 3.7% |

| Base Year | 2022 |

| Forecasted years | 2024 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SSP Manufacturing, Inc., Apple Rubber, Martin’s Rubber Company, Elasto Proxy, THE RUBBER COMPANY, Seal & Design Company, DP Seals, Goodyear Rubber Company, Atlantic Gasket Corporation, Dawn, Custom Rubber, CGR, Satori Seal, Hennig Gasket & Seals, KINDDI, GAOXIN RUBBER&PLASTIC, ERIKS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |