What is Screen Printing Mesh- Global Market?

Screen printing mesh is a crucial component in the screen printing process, which is a popular method for transferring ink onto various substrates. This mesh is typically made from materials like polyester, nylon, stainless steel, and tungsten, each offering unique properties that cater to different printing needs. The global market for screen printing mesh is driven by its widespread application across various industries, including textiles, ceramics, electronics, and solar cells. The demand for high-quality prints and the ability to produce intricate designs have fueled the growth of this market. Screen printing mesh is valued for its durability, precision, and versatility, making it an essential tool for manufacturers seeking to produce high-quality printed products. The market is characterized by a diverse range of mesh types, each designed to meet specific printing requirements, such as mesh count, thread diameter, and weave type. As industries continue to innovate and seek more efficient printing solutions, the demand for advanced screen printing mesh is expected to grow, further solidifying its importance in the global market. The adaptability of screen printing mesh to various applications ensures its continued relevance and expansion in the coming years.

Polyester, Nylon, Stainless Steel, Tungsten, Others in the Screen Printing Mesh- Global Market:

Polyester, nylon, stainless steel, tungsten, and other materials each play a significant role in the screen printing mesh market, offering distinct advantages and catering to different industry needs. Polyester is the most commonly used material due to its excellent elasticity, durability, and resistance to chemicals and moisture. It is ideal for applications requiring high tension and precision, such as textile printing, where it provides consistent and high-quality prints. Nylon, on the other hand, is known for its flexibility and strength, making it suitable for printing on uneven surfaces or substrates that require a softer touch. Its ability to stretch without breaking makes it a preferred choice for ceramic and glass printing, where intricate designs are often required. Stainless steel mesh is renowned for its strength, durability, and resistance to high temperatures, making it ideal for applications in the electronics and solar cell industries. Its rigidity ensures precise and accurate prints, which are crucial for producing electronic components and solar panels. Tungsten mesh, though less common, offers exceptional heat resistance and is used in specialized applications where extreme conditions are present. Other materials, such as silk and synthetic fibers, are also used in niche markets, providing unique properties that cater to specific printing needs. The choice of material depends on various factors, including the type of substrate, the complexity of the design, and the desired print quality. As industries continue to evolve and demand more sophisticated printing solutions, the development and adoption of advanced screen printing mesh materials are expected to rise, driving innovation and growth in the global market. Each material's unique properties contribute to the versatility and adaptability of screen printing mesh, ensuring its continued relevance across diverse industries.

Textile, Ceramic and Glass, Electronics, Solar Cells, Others in the Screen Printing Mesh- Global Market:

Screen printing mesh finds extensive usage across various industries, each benefiting from its unique properties and capabilities. In the textile industry, screen printing mesh is used to create vibrant and intricate designs on fabrics, ranging from clothing to home textiles. The ability to produce high-quality prints with precise color registration makes it a preferred choice for fashion designers and manufacturers. In the ceramic and glass industries, screen printing mesh is used to apply decorative patterns and functional coatings on products such as tiles, glassware, and automotive glass. The mesh's ability to handle different ink viscosities and produce fine details ensures that the final products meet aesthetic and functional requirements. In the electronics industry, screen printing mesh is crucial for manufacturing printed circuit boards (PCBs), sensors, and other electronic components. The precision and accuracy offered by the mesh are essential for creating intricate circuits and ensuring the reliability of electronic devices. Solar cell manufacturing also relies on screen printing mesh to apply conductive and anti-reflective coatings on solar panels. The mesh's ability to produce uniform and consistent prints is vital for maximizing the efficiency and performance of solar cells. Other industries, such as packaging and advertising, also utilize screen printing mesh for creating eye-catching designs and branding materials. The versatility and adaptability of screen printing mesh make it an indispensable tool for manufacturers seeking to produce high-quality printed products across various applications. As industries continue to innovate and demand more efficient and sustainable printing solutions, the usage of screen printing mesh is expected to expand, further solidifying its importance in the global market.

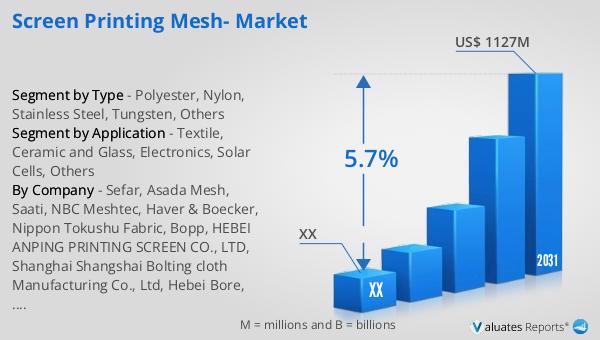

Screen Printing Mesh- Global Market Outlook:

The global screen printing mesh market is poised for significant growth, with its value projected to increase from an estimated US$ 766 million in 2024 to a readjusted size of US$ 1127 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold approximately 44% of the market share. The Asia-Pacific region emerges as the largest market, accounting for about 75% of the total share, followed by Europe and North America, which hold shares of 12% and 10%, respectively. Among the various product types, stainless steel is the most prominent segment, occupying a 37% share of the market. In terms of application, the electronics sector leads with a 33% share, highlighting the critical role of screen printing mesh in the production of electronic components. The market's growth is driven by the increasing demand for high-quality printed products across various industries, coupled with advancements in printing technology and materials. As manufacturers continue to seek innovative solutions to meet evolving consumer needs, the screen printing mesh market is expected to witness sustained growth and development.

| Report Metric | Details |

| Report Name | Screen Printing Mesh- Market |

| Forecasted market size in 2031 | US$ 1127 million |

| CAGR | 5.7% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sefar, Asada Mesh, Saati, NBC Meshtec, Haver & Boecker, Nippon Tokushu Fabric, Bopp, HEBEI ANPING PRINTING SCREEN CO., LTD, Shanghai Shangshai Bolting cloth Manufacturing Co., Ltd, Hebei Bore, VEKEN, YKM Group, MAISHI MFG, Eastar Filtration Industry Co., Ltd, Extris Srl |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |