What is Robot Teach Pendant- Global Market?

The Robot Teach Pendant is an essential tool in the global robotics market, serving as a handheld device that allows operators to interact with and control robots. This device is crucial for programming and teaching robots specific tasks, making it a vital component in industries that rely heavily on automation. The global market for Robot Teach Pendants is experiencing significant growth due to the increasing adoption of robotics across various sectors such as manufacturing, automotive, and electronics. These pendants are designed to be user-friendly, enabling operators to easily program robots without needing extensive technical knowledge. The market is driven by advancements in technology that enhance the functionality and ease of use of these devices. As industries continue to automate processes to improve efficiency and reduce labor costs, the demand for Robot Teach Pendants is expected to rise. The market is also influenced by the growing trend of Industry 4.0, which emphasizes the integration of digital technologies in manufacturing. This trend is pushing companies to adopt more sophisticated robotic systems, further boosting the demand for teach pendants. Overall, the Robot Teach Pendant market is poised for growth as industries continue to embrace automation and digital transformation.

Electric Drive Robots, Hydraulic Drive Robots, Pneumatic Drive Robots in the Robot Teach Pendant- Global Market:

Electric Drive Robots, Hydraulic Drive Robots, and Pneumatic Drive Robots are three primary types of robots that utilize the Robot Teach Pendant for programming and operation. Electric Drive Robots are the most prevalent in the market, primarily due to their energy efficiency, precision, and ease of control. These robots are powered by electric motors, which provide smooth and accurate movements, making them ideal for applications that require high precision, such as assembly and material handling. The teach pendant allows operators to program these robots with ease, facilitating quick adjustments and reprogramming as needed. Hydraulic Drive Robots, on the other hand, are powered by hydraulic actuators, which provide significant force and power. These robots are typically used in applications that require heavy lifting or high force, such as in the automotive and construction industries. The teach pendant is crucial for programming these robots to perform complex tasks that require precise control of force and movement. Pneumatic Drive Robots are powered by compressed air and are known for their speed and simplicity. These robots are often used in applications that require rapid movements, such as pick-and-place operations in manufacturing. The teach pendant enables operators to program these robots quickly, allowing for efficient operation and minimal downtime. Each type of robot has its unique advantages and is suited for specific applications, but all rely on the teach pendant for effective programming and operation. The global market for these robots is expanding as industries continue to seek automation solutions that improve efficiency and productivity. The teach pendant plays a critical role in this expansion by providing a user-friendly interface for programming and controlling robots, making it easier for companies to integrate robotics into their operations. As technology continues to advance, the capabilities of teach pendants are expected to improve, further enhancing the functionality and versatility of Electric Drive Robots, Hydraulic Drive Robots, and Pneumatic Drive Robots.

Material Handling, Welding Application, Assembling, Other Applications in the Robot Teach Pendant- Global Market:

The Robot Teach Pendant is widely used in various applications, including material handling, welding, assembling, and other specialized tasks. In material handling, the teach pendant is essential for programming robots to move, sort, and manage materials efficiently. This application is crucial in industries such as logistics and warehousing, where robots are used to automate the movement of goods, reducing the need for manual labor and increasing operational efficiency. The teach pendant allows operators to program robots to handle different types of materials and adapt to changes in the production line quickly. In welding applications, the teach pendant is used to program robots to perform precise welding tasks, ensuring high-quality welds and consistent results. This is particularly important in the automotive and aerospace industries, where precision and consistency are critical. The teach pendant enables operators to adjust welding parameters easily, ensuring that robots can adapt to different welding requirements and materials. In assembling applications, the teach pendant is used to program robots to perform complex assembly tasks, such as fitting components together with high precision. This is essential in industries like electronics and consumer goods, where robots are used to assemble intricate products with numerous small parts. The teach pendant allows operators to program robots to perform these tasks accurately and efficiently, reducing the risk of errors and improving product quality. In addition to these applications, the teach pendant is also used in other specialized tasks, such as painting, inspection, and packaging. In each of these applications, the teach pendant provides a user-friendly interface for programming and controlling robots, enabling operators to optimize robot performance and adapt to changing production needs. As industries continue to automate processes and integrate robotics into their operations, the demand for Robot Teach Pendants is expected to grow, driven by the need for efficient and flexible automation solutions.

Robot Teach Pendant- Global Market Outlook:

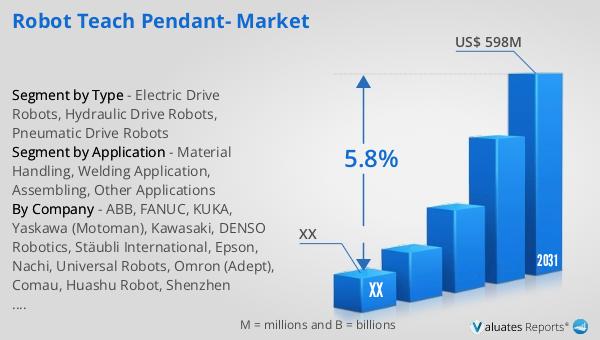

The global market for Robot Teach Pendants is projected to grow significantly, with an estimated value of US$ 405 million in 2024, expected to reach approximately US$ 598 million by 2031. This growth is driven by a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold about 53% of the market share. The Asia-Pacific region is the largest market for Robot Teach Pendants, accounting for approximately 69% of the global market share. This is followed by Europe and North America, which hold shares of 17% and 9%, respectively. In terms of product type, Electric Drive Robots represent the largest segment, occupying about 59% of the market share. This is due to their energy efficiency, precision, and ease of control, making them ideal for a wide range of applications. In terms of application, material handling is the largest segment, accounting for approximately 50% of the market share. This is driven by the increasing demand for automation in industries such as logistics and warehousing, where robots are used to move and manage materials efficiently. Overall, the Robot Teach Pendant market is poised for growth as industries continue to embrace automation and digital transformation, driven by the need for efficient and flexible automation solutions.

| Report Metric | Details |

| Report Name | Robot Teach Pendant- Market |

| Forecasted market size in 2031 | US$ 598 million |

| CAGR | 5.8% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ABB, FANUC, KUKA, Yaskawa (Motoman), Kawasaki, DENSO Robotics, Stäubli International, Epson, Nachi, Universal Robots, Omron (Adept), Comau, Huashu Robot, Shenzhen Lavichip, Mitsubishi Electric Corporation, Festo, Yamaha, AUBO, Peitian Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |