What is Global Welding Fire Blankets Market?

The Global Welding Fire Blankets Market refers to the industry focused on the production and distribution of fire-resistant blankets specifically designed for welding applications. These blankets are crucial safety tools used to protect workers and equipment from sparks, spatter, and intense heat generated during welding processes. Made from materials like fiberglass, silica, or other fire-retardant fabrics, these blankets are essential in preventing fires and ensuring safety in various industrial settings. The market for welding fire blankets is driven by the increasing emphasis on workplace safety and the growing demand for welding activities across different sectors such as construction, automotive, and manufacturing. As industries continue to expand and prioritize safety measures, the need for effective fire protection solutions like welding fire blankets is expected to rise. These blankets not only safeguard workers but also help in maintaining operational efficiency by minimizing the risk of fire-related accidents. The global market is characterized by a diverse range of products catering to different needs, with manufacturers continuously innovating to enhance the performance and durability of these safety tools. Overall, the Global Welding Fire Blankets Market plays a vital role in promoting safety and preventing fire hazards in industrial environments.

in the Global Welding Fire Blankets Market:

In the Global Welding Fire Blankets Market, various types of blankets are utilized by customers based on their specific needs and applications. These blankets are primarily categorized by the materials they are made from, each offering distinct advantages and suitability for different environments. Fiberglass welding blankets are among the most common types, known for their excellent heat resistance and durability. They are lightweight, flexible, and can withstand high temperatures, making them ideal for general welding applications. Another popular type is the silica welding blanket, which offers superior heat resistance compared to fiberglass. Silica blankets can endure extreme temperatures and are often used in more demanding welding environments where higher levels of protection are required. Ceramic fiber welding blankets are another option, known for their exceptional thermal insulation properties. These blankets are suitable for applications involving prolonged exposure to high temperatures. Additionally, carbon fiber welding blankets are used for their lightweight nature and high strength, providing effective protection in various welding scenarios. Each type of welding blanket is designed to meet specific safety standards and requirements, ensuring optimal protection for workers and equipment. Customers choose the appropriate type based on factors such as the intensity of the welding process, the level of heat exposure, and the specific safety regulations of their industry. For instance, in industries where welding is a frequent activity, such as construction or automotive manufacturing, the choice of welding blanket may depend on the specific welding techniques employed and the materials being welded. In construction, where welding is often performed in open or outdoor environments, fiberglass or silica blankets may be preferred for their durability and resistance to environmental factors. In contrast, industries like aerospace or shipbuilding, which involve more complex welding processes and higher temperatures, may opt for ceramic or carbon fiber blankets to ensure maximum protection. The selection of welding fire blankets is also influenced by the need for compliance with safety standards and regulations. Different regions and industries have specific safety requirements that dictate the type of fire protection equipment to be used. Manufacturers in the Global Welding Fire Blankets Market continuously innovate to develop products that meet these evolving standards, incorporating advanced materials and technologies to enhance the performance and safety of their blankets. This includes features such as improved heat resistance, increased flexibility, and enhanced durability to withstand the rigors of industrial use. Furthermore, the market offers a range of sizes and configurations to accommodate different welding setups and environments. From small, portable blankets for localized protection to large, heavy-duty blankets for extensive coverage, customers have a variety of options to choose from. This versatility allows businesses to tailor their fire protection solutions to their specific needs, ensuring comprehensive safety measures are in place. Overall, the Global Welding Fire Blankets Market provides a diverse array of products designed to meet the varied demands of different industries and applications. By offering a range of materials, sizes, and features, manufacturers cater to the unique requirements of their customers, ensuring effective fire protection and safety in welding operations. As industries continue to prioritize safety and compliance, the demand for high-quality welding fire blankets is expected to grow, driving further innovation and development in the market.

Construction Industry, Energy, Marine Industry, Automotive Industry, Utilities, Others in the Global Welding Fire Blankets Market:

The usage of Global Welding Fire Blankets Market spans across several key industries, each with its unique requirements and applications. In the construction industry, welding fire blankets are essential for protecting workers and equipment from the sparks and heat generated during welding activities. Construction sites often involve welding in open or outdoor environments, where the risk of fire is heightened. Welding fire blankets provide a crucial layer of protection, preventing fires and ensuring the safety of workers and the surrounding area. They are used to cover flammable materials, shield workers from heat, and create safe zones for welding operations. In the energy sector, welding fire blankets play a vital role in maintaining safety during the construction and maintenance of energy infrastructure. Whether it's in oil and gas facilities, power plants, or renewable energy installations, welding activities are common, and the risk of fire is a significant concern. Fire blankets are used to protect sensitive equipment, prevent the spread of sparks, and ensure compliance with safety regulations. In the marine industry, welding fire blankets are used extensively in shipbuilding and repair activities. The confined spaces and complex structures of ships require specialized fire protection solutions to prevent fires and ensure the safety of workers. Welding fire blankets are used to cover flammable materials, protect equipment, and create safe working environments in shipyards and onboard vessels. In the automotive industry, welding fire blankets are used in manufacturing and repair processes to protect workers and equipment from the heat and sparks generated during welding. They are used to cover sensitive components, shield workers from heat, and prevent fires in production lines and repair shops. In the utilities sector, welding fire blankets are used in the maintenance and repair of infrastructure such as pipelines, power lines, and water systems. These activities often involve welding in challenging environments, where the risk of fire is a significant concern. Fire blankets provide essential protection, ensuring the safety of workers and the integrity of the infrastructure. In addition to these industries, welding fire blankets are used in various other sectors where welding activities are common. This includes manufacturing, aerospace, and transportation, among others. In each of these industries, welding fire blankets provide a critical layer of protection, preventing fires and ensuring the safety of workers and equipment. Overall, the usage of Global Welding Fire Blankets Market is widespread across multiple industries, each with its unique requirements and applications. By providing effective fire protection solutions, welding fire blankets play a crucial role in ensuring safety and compliance in welding operations. As industries continue to prioritize safety and compliance, the demand for high-quality welding fire blankets is expected to grow, driving further innovation and development in the market.

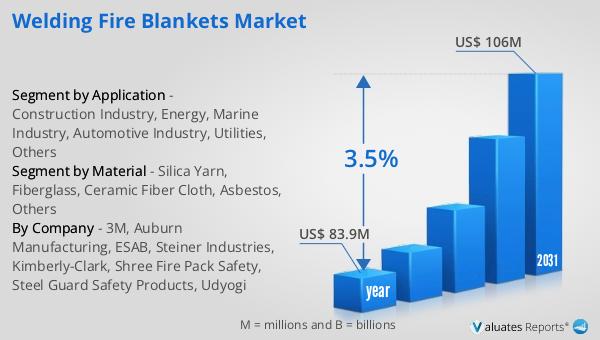

Global Welding Fire Blankets Market Outlook:

The global market for Welding Fire Blankets was valued at $83.9 million in 2024, and it is anticipated to expand to a revised size of $106 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period. This growth trajectory underscores the increasing demand for welding fire blankets across various industries, driven by the heightened focus on workplace safety and the expansion of industrial activities worldwide. As industries such as construction, automotive, and energy continue to grow, the need for effective fire protection solutions becomes more critical. Welding fire blankets, with their ability to prevent fires and protect workers and equipment, are becoming an essential component of safety protocols in these sectors. The projected growth of the market also highlights the ongoing innovation and development within the industry, as manufacturers strive to enhance the performance and durability of their products to meet the evolving needs of their customers. With the increasing emphasis on safety and compliance, the demand for high-quality welding fire blankets is expected to continue rising, driving further growth and development in the market. As a result, the Global Welding Fire Blankets Market is poised for significant expansion in the coming years, offering opportunities for manufacturers and suppliers to capitalize on the growing demand for fire protection solutions.

| Report Metric | Details |

| Report Name | Welding Fire Blankets Market |

| Accounted market size in year | US$ 83.9 million |

| Forecasted market size in 2031 | US$ 106 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Material |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | 3M, Auburn Manufacturing, ESAB, Steiner Industries, Kimberly-Clark, Shree Fire Pack Safety, Steel Guard Safety Products, Udyogi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |