What is Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market?

Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market is a specialized segment within the broader medical materials market, focusing on the use of high impact polystyrene in medical applications. HIPS is a versatile plastic known for its toughness, impact resistance, and ease of fabrication, making it an ideal choice for various medical applications. In the opaque rigid medical market, HIPS is particularly valued for its ability to provide a strong, durable, and cost-effective solution for medical device manufacturers. Its opacity is crucial in applications where light sensitivity is a concern, ensuring that the contents of medical devices or packaging are protected from light exposure. Additionally, HIPS is known for its excellent machinability, allowing for precise and intricate designs that are often required in medical applications. The material's compatibility with various sterilization methods, such as gamma radiation and ethylene oxide, further enhances its suitability for medical use. As the demand for reliable and affordable medical devices continues to grow, the role of HIPS in the opaque rigid medical market is expected to expand, driven by its unique properties and adaptability to various medical needs.

Extrusion Molding HIPS, Injection Molding HIPS, Other in the Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market:

Extrusion molding and injection molding are two primary methods used to process High Impact Poly Styrene (HIPS) for the opaque rigid medical market, each offering distinct advantages and applications. Extrusion molding involves forcing molten HIPS through a die to create continuous shapes, such as sheets or tubes, which can then be cut to desired lengths. This method is particularly beneficial for producing large volumes of uniform products, making it ideal for applications like medical trays and packaging materials. The extrusion process allows for the creation of thin, lightweight, yet durable products that are essential in medical settings where sterility and ease of handling are paramount. On the other hand, injection molding involves injecting molten HIPS into a mold cavity, where it cools and solidifies into the desired shape. This method is highly versatile and is used to produce complex and detailed components, such as medical device housings and intricate parts that require precision and consistency. Injection molding is favored for its ability to produce high-quality parts with tight tolerances, essential for ensuring the reliability and safety of medical devices. Additionally, the process is efficient and cost-effective, allowing for the production of large quantities of parts with minimal waste. Beyond extrusion and injection molding, other methods such as thermoforming and blow molding are also employed in the processing of HIPS for medical applications. Thermoforming involves heating HIPS sheets until pliable and then forming them over a mold to create specific shapes. This method is particularly useful for creating custom-fit packaging and protective covers for medical devices. Blow molding, although less common in the medical field, is used to create hollow parts, such as containers and bottles, by inflating a heated HIPS parison within a mold. Each of these molding techniques offers unique benefits and is chosen based on the specific requirements of the medical application, such as the desired shape, size, and production volume. The versatility of HIPS, combined with these advanced processing techniques, ensures that it remains a critical material in the opaque rigid medical market, meeting the diverse needs of healthcare providers and patients alike.

Work-in-progress Trays, Thermoformed Pharmaceutical Packaging, Packaging for Economical Medical Devices, Others in the Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market:

The usage of Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market spans several critical areas, including work-in-progress trays, thermoformed pharmaceutical packaging, packaging for economical medical devices, and other applications. Work-in-progress trays are essential in medical settings for organizing and transporting components during the assembly and manufacturing of medical devices. HIPS is an ideal material for these trays due to its durability, impact resistance, and ease of cleaning, ensuring that components remain secure and uncontaminated throughout the production process. The trays can be customized to fit specific components, providing a tailored solution that enhances efficiency and reduces the risk of errors. In thermoformed pharmaceutical packaging, HIPS is used to create blister packs and other protective enclosures that safeguard medications from environmental factors such as moisture and light. The material's opacity is particularly beneficial in protecting light-sensitive drugs, ensuring their efficacy and safety. Additionally, HIPS offers excellent barrier properties and can be easily sealed, providing a reliable and tamper-evident packaging solution. For economical medical devices, HIPS is used to produce cost-effective yet high-quality components that meet stringent medical standards. Its versatility allows for the creation of complex shapes and designs, enabling manufacturers to produce innovative devices that improve patient care while keeping costs manageable. The material's compatibility with various sterilization methods ensures that these devices remain safe and effective for use in medical environments. Beyond these specific applications, HIPS is also used in other areas of the medical market, such as diagnostic equipment housings, surgical instrument handles, and laboratory equipment. Its combination of strength, versatility, and cost-effectiveness makes it a preferred choice for manufacturers looking to produce reliable and durable medical products. As the demand for affordable and high-quality medical solutions continues to rise, the role of HIPS in the opaque rigid medical market is expected to grow, driven by its ability to meet the diverse needs of healthcare providers and patients.

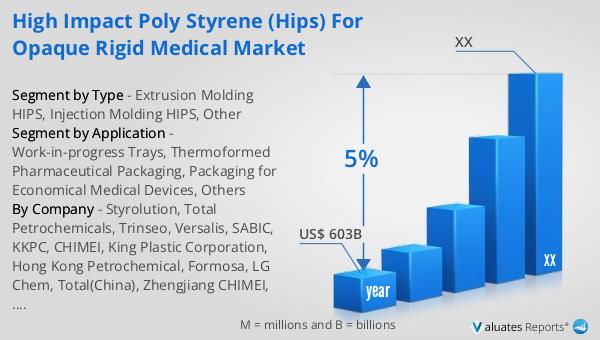

Global High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion in 2023, with an anticipated growth rate of 5% CAGR over the next six years. This growth is indicative of the increasing demand for advanced medical technologies and the continuous innovation within the healthcare sector. The expansion of the medical device market is driven by several factors, including the rising prevalence of chronic diseases, an aging global population, and the growing emphasis on improving healthcare infrastructure worldwide. As healthcare systems strive to enhance patient outcomes and reduce costs, the demand for efficient and cost-effective medical devices is expected to rise. High Impact Poly Styrene (HIPS) plays a crucial role in this market by providing a reliable and affordable material solution for the production of various medical devices and packaging. Its unique properties, such as impact resistance, ease of fabrication, and compatibility with sterilization processes, make it an ideal choice for manufacturers looking to meet the evolving needs of the healthcare industry. As the market continues to grow, the importance of materials like HIPS in supporting the development and production of innovative medical solutions cannot be overstated. The ongoing advancements in medical technology and the increasing focus on patient-centric care are likely to further drive the demand for HIPS in the opaque rigid medical market, ensuring its continued relevance and contribution to the global healthcare landscape.

| Report Metric | Details |

| Report Name | High Impact Poly Styrene (HIPS) for Opaque Rigid Medical Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Styrolution, Total Petrochemicals, Trinseo, Versalis, SABIC, KKPC, CHIMEI, King Plastic Corporation, Hong Kong Petrochemical, Formosa, LG Chem, Total(China), Zhengjiang CHIMEI, Formosa Plastics, Astor Chemical Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |