What is Global Wobbler Feeders Market?

The Global Wobbler Feeders Market is a specialized segment within the broader industrial equipment industry, focusing on the production and distribution of wobbler feeders. These feeders are essential components in various heavy-duty applications, primarily used to handle bulk materials. They are designed to manage and process large volumes of materials, such as rocks, minerals, and other aggregates, by providing a consistent and controlled feed rate. Wobbler feeders are particularly valued for their ability to handle wet, sticky, or abrasive materials that might clog or damage other types of feeders. Their unique design, which includes rotating elliptical bars, allows them to separate fines and smaller particles from larger materials, ensuring efficient processing and reducing wear and tear on subsequent equipment. This makes them indispensable in industries like mining, construction, and aggregate processing, where the efficient handling of raw materials is crucial. The market for wobbler feeders is driven by the demand for efficient material handling solutions, technological advancements in feeder design, and the growth of industries that rely on bulk material processing. As industries continue to expand and modernize, the need for reliable and efficient wobbler feeders is expected to grow, making this market a vital component of the global industrial landscape.

Capacity (mtph):200-300, Capacity (mtph):300-400, Capacity (mtph):400-600, Others in the Global Wobbler Feeders Market:

In the Global Wobbler Feeders Market, capacity is a critical factor that determines the efficiency and suitability of a feeder for specific applications. The capacity of a wobbler feeder is typically measured in metric tons per hour (mtph), and it indicates the volume of material the feeder can process within an hour. Different capacity ranges cater to various industrial needs, ensuring that operations can be tailored to specific requirements. For instance, a capacity of 200-300 mtph is suitable for smaller operations or those with moderate material handling needs. These feeders are often used in applications where space is limited, or the volume of material to be processed is not excessively high. They provide a balance between efficiency and cost, making them an attractive option for businesses looking to optimize their operations without incurring significant expenses. On the other hand, feeders with a capacity of 300-400 mtph are designed for medium-sized operations. They offer a higher throughput, making them ideal for industries that require a steady and reliable flow of materials. These feeders are often used in mining and construction applications, where the demand for processed materials is consistent and substantial. The increased capacity allows for more efficient processing, reducing downtime and improving overall productivity. For larger operations, feeders with a capacity of 400-600 mtph are essential. These high-capacity feeders are designed to handle significant volumes of material, making them suitable for large-scale mining operations, aggregate processing plants, and other heavy-duty applications. Their robust design ensures they can withstand the rigors of continuous operation, providing a reliable solution for industries that demand high throughput and efficiency. Additionally, there are feeders with capacities beyond 600 mtph, categorized as "Others." These feeders are tailored for the most demanding applications, where the volume of material to be processed is exceptionally high. They are often custom-designed to meet the specific needs of large industrial operations, ensuring that even the most challenging material handling requirements can be met. The availability of various capacity options in the Global Wobbler Feeders Market ensures that businesses can find the right solution for their specific needs, optimizing their operations and enhancing productivity.

Aggregate, Mining, Others in the Global Wobbler Feeders Market:

The Global Wobbler Feeders Market plays a crucial role in various industries, particularly in aggregate processing, mining, and other sectors that require efficient material handling solutions. In the aggregate industry, wobbler feeders are used to process raw materials such as sand, gravel, and crushed stone. These feeders help in separating fines and smaller particles from larger aggregates, ensuring that the final product meets the required specifications. By providing a consistent and controlled feed rate, wobbler feeders enhance the efficiency of aggregate processing plants, reducing downtime and improving overall productivity. In the mining industry, wobbler feeders are indispensable for handling bulk materials such as ores and minerals. They are designed to manage the challenging conditions often encountered in mining operations, including wet, sticky, or abrasive materials. The ability of wobbler feeders to separate fines and smaller particles from larger materials ensures that the subsequent processing equipment operates efficiently, reducing wear and tear and minimizing maintenance costs. This makes them a valuable asset in mining operations, where the efficient handling of raw materials is crucial for profitability. Beyond aggregate and mining applications, wobbler feeders are also used in other industries that require reliable material handling solutions. For instance, they are employed in the cement industry to process raw materials such as limestone and clay. The consistent feed rate provided by wobbler feeders ensures that the cement production process runs smoothly, reducing the risk of bottlenecks and improving overall efficiency. Additionally, wobbler feeders are used in industries such as recycling, where they help in processing materials like scrap metal and construction debris. By providing a controlled feed rate and separating fines from larger materials, wobbler feeders enhance the efficiency of recycling operations, ensuring that valuable materials are recovered and processed effectively. The versatility and reliability of wobbler feeders make them an essential component in various industries, providing efficient material handling solutions that enhance productivity and profitability.

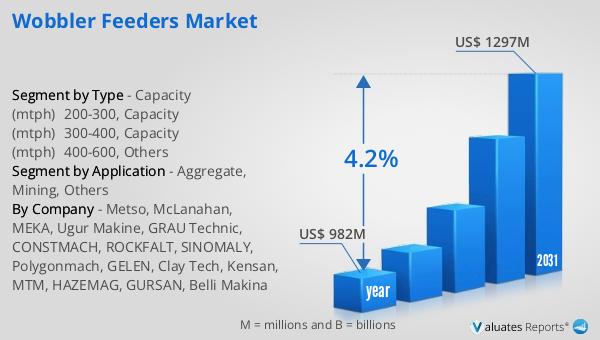

Global Wobbler Feeders Market Outlook:

The global market for Wobbler Feeders was valued at approximately $982 million in 2024, and it is anticipated to grow to a revised size of around $1,297 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This steady growth is indicative of the increasing demand for efficient material handling solutions across various industries. As industries continue to expand and modernize, the need for reliable and efficient wobbler feeders is expected to grow, making this market a vital component of the global industrial landscape. The projected growth in the market can be attributed to several factors, including technological advancements in feeder design, the expansion of industries that rely on bulk material processing, and the increasing focus on operational efficiency and productivity. As businesses strive to optimize their operations and reduce costs, the demand for high-quality wobbler feeders is likely to increase, driving market growth. Additionally, the growing emphasis on sustainability and environmental responsibility is expected to further boost the demand for wobbler feeders, as they help in reducing waste and improving the efficiency of material handling processes. Overall, the Global Wobbler Feeders Market is poised for significant growth in the coming years, driven by the increasing demand for efficient and reliable material handling solutions across various industries.

| Report Metric | Details |

| Report Name | Wobbler Feeders Market |

| Accounted market size in year | US$ 982 million |

| Forecasted market size in 2031 | US$ 1297 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Metso, McLanahan, MEKA, Ugur Makine, GRAU Technic, CONSTMACH, ROCKFALT, SINOMALY, Polygonmach, GELEN, Clay Tech, Kensan, MTM, HAZEMAG, GURSAN, Belli Makina |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |