What is Global Plastic Thermoforming Machine Market?

The Global Plastic Thermoforming Machine Market refers to the industry focused on the production and sale of machines used to shape plastic materials through a process called thermoforming. Thermoforming involves heating a plastic sheet until it becomes pliable, then forming it over a mold to create a specific shape. This process is widely used in various industries due to its efficiency and cost-effectiveness in producing large quantities of uniform plastic products. The market for these machines is driven by the increasing demand for plastic products in sectors such as packaging, automotive, and consumer goods. As industries continue to seek sustainable and efficient manufacturing processes, the demand for advanced thermoforming machines is expected to grow. These machines vary in complexity and capability, ranging from basic manual models to highly automated systems that offer precision and speed. The market is characterized by continuous technological advancements aimed at improving the efficiency, speed, and environmental impact of the thermoforming process. Companies in this market are also focusing on developing machines that can handle a wider range of materials, including biodegradable plastics, to meet the growing demand for sustainable solutions. Overall, the Global Plastic Thermoforming Machine Market plays a crucial role in supporting the production needs of various industries worldwide.

Automatic, Semi-automatic in the Global Plastic Thermoforming Machine Market:

In the Global Plastic Thermoforming Machine Market, machines are generally categorized into two main types: automatic and semi-automatic. Automatic thermoforming machines are designed to perform the entire thermoforming process with minimal human intervention. These machines are equipped with advanced technology that allows them to handle the heating, forming, and trimming of plastic sheets automatically. The primary advantage of automatic machines is their ability to produce large volumes of products quickly and consistently, making them ideal for high-demand industries such as food packaging and automotive manufacturing. They are often integrated with computerized systems that allow for precise control over the forming process, ensuring high-quality output with minimal waste. Additionally, automatic machines can be programmed to produce a wide variety of shapes and sizes, offering flexibility to manufacturers. On the other hand, semi-automatic thermoforming machines require some level of human involvement in the process. While they still automate significant portions of the thermoforming process, such as heating and forming, operators are typically needed to load and unload materials or to perform certain adjustments during production. Semi-automatic machines are often favored by smaller manufacturers or those with lower production volumes, as they tend to be more cost-effective than fully automatic systems. They offer a balance between automation and manual control, allowing operators to make real-time adjustments to the process as needed. This can be particularly beneficial for custom or small-batch production runs where flexibility and adaptability are important. Both automatic and semi-automatic machines have their place in the market, with the choice between them largely depending on the specific needs and scale of production for a given manufacturer. As technology continues to advance, the line between these two types of machines is becoming increasingly blurred, with many semi-automatic machines incorporating more automated features to enhance efficiency and output quality. The ongoing development of these machines is focused on improving their energy efficiency, reducing material waste, and expanding their capabilities to handle a broader range of materials, including eco-friendly options. This evolution is driven by the growing demand for sustainable manufacturing practices and the need for machines that can adapt to changing industry requirements. In summary, the Global Plastic Thermoforming Machine Market offers a range of options for manufacturers, from highly automated systems that maximize efficiency and output to more flexible semi-automatic machines that provide a balance of control and cost-effectiveness. As industries continue to evolve, the demand for versatile and efficient thermoforming solutions is expected to drive further innovation and growth in this market.

Food Packaging, Medical and Pharmaceutical Packaging, Consumer Goods Packaging, Others in the Global Plastic Thermoforming Machine Market:

The Global Plastic Thermoforming Machine Market finds extensive application across various sectors, with food packaging being one of the most significant areas of use. In the food industry, thermoforming machines are employed to create a wide range of packaging solutions, from simple trays and containers to complex multi-compartment packages. These machines offer the ability to produce packaging that is not only functional but also visually appealing, which is crucial in a competitive market where packaging can influence consumer purchasing decisions. The ability to quickly and efficiently produce large volumes of packaging makes thermoforming machines an essential tool for food manufacturers looking to meet the demands of both retailers and consumers. In the medical and pharmaceutical sectors, thermoforming machines are used to produce sterile and secure packaging solutions for a variety of products, including medical devices, surgical instruments, and pharmaceuticals. The precision and reliability of thermoforming machines ensure that packaging meets the stringent standards required in these industries, providing protection against contamination and ensuring product integrity. The ability to produce custom packaging solutions also allows manufacturers to cater to the specific needs of different medical products, enhancing their functionality and ease of use. In the consumer goods sector, thermoforming machines are used to create packaging for a wide range of products, from electronics and household items to personal care products. The versatility of thermoforming allows manufacturers to produce packaging that not only protects products during transportation and storage but also enhances their shelf appeal. This is particularly important in a market where packaging plays a key role in brand differentiation and consumer engagement. The ability to produce packaging in various shapes, sizes, and designs allows manufacturers to create unique and eye-catching solutions that stand out on store shelves. Beyond these primary sectors, thermoforming machines are also used in other industries, such as automotive and construction, where they are employed to produce components and parts that require precise shaping and durability. The ongoing development of thermoforming technology is focused on expanding its applications and improving its efficiency, with an emphasis on sustainability and the use of eco-friendly materials. As industries continue to seek innovative and cost-effective solutions, the Global Plastic Thermoforming Machine Market is expected to play a crucial role in supporting their production needs.

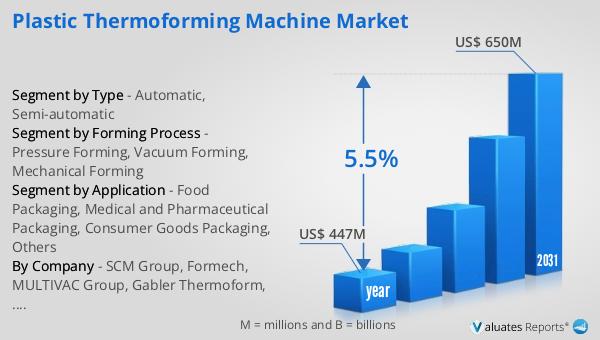

Global Plastic Thermoforming Machine Market Outlook:

In 2024, the global market for Plastic Thermoforming Machines was valued at approximately $447 million. Looking ahead, this market is anticipated to grow significantly, reaching an estimated value of $650 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.5% over the forecast period. The increasing demand for efficient and cost-effective manufacturing solutions across various industries is a key driver of this growth. As companies strive to enhance their production capabilities and meet the evolving needs of consumers, the adoption of advanced thermoforming machines is expected to rise. These machines offer numerous advantages, including the ability to produce high-quality products at a rapid pace, which is essential in today's fast-paced market environment. Additionally, the growing emphasis on sustainability and the use of eco-friendly materials is likely to further boost the demand for thermoforming machines, as manufacturers seek to reduce their environmental impact while maintaining production efficiency. The market's expansion is also supported by continuous technological advancements, which are enhancing the capabilities and versatility of thermoforming machines. As a result, the Global Plastic Thermoforming Machine Market is poised for robust growth, driven by the increasing need for innovative and sustainable manufacturing solutions.

| Report Metric | Details |

| Report Name | Plastic Thermoforming Machine Market |

| Accounted market size in year | US$ 447 million |

| Forecasted market size in 2031 | US$ 650 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Forming Process |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SCM Group, Formech, MULTIVAC Group, Gabler Thermoform, INPAK Makina, WM Thermoforming Machines, Kiefel, BMG, FoodPak, Zed Industries, Frimo Inc., IMA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |