What is Global Cemented Carbide Recycling Market?

The Global Cemented Carbide Recycling Market is a specialized segment within the broader recycling industry, focusing on the recovery and reuse of cemented carbide materials. Cemented carbides are composite materials made from hard carbide particles bonded together by a metallic binder, typically cobalt. These materials are highly valued for their exceptional hardness, wear resistance, and ability to withstand high temperatures, making them indispensable in various industrial applications. The recycling market for cemented carbide is driven by the need to conserve resources, reduce environmental impact, and lower production costs. By recycling used or scrap cemented carbide products, industries can recover valuable materials like tungsten, cobalt, and other metals, which can then be reused in the production of new cemented carbide products. This not only helps in reducing the demand for virgin raw materials but also minimizes the carbon footprint associated with mining and processing these materials. The market is witnessing growth due to increasing awareness about sustainable practices and the economic benefits of recycling. As industries continue to seek ways to enhance their sustainability efforts, the demand for cemented carbide recycling is expected to rise, contributing to a more circular economy.

Tungsten Carbide(WC), Titanium Carbide(TiC), Tantalum Carbide(TaC) in the Global Cemented Carbide Recycling Market:

Tungsten Carbide (WC), Titanium Carbide (TiC), and Tantalum Carbide (TaC) are key components in the Global Cemented Carbide Recycling Market, each offering unique properties that make them valuable for various applications. Tungsten Carbide is renowned for its exceptional hardness and high melting point, making it ideal for cutting tools, mining tools, and wear-resistant applications. Its ability to maintain sharpness and resist wear under extreme conditions makes it a preferred choice in industries such as metalworking, mining, and construction. Recycling tungsten carbide involves recovering tungsten and cobalt, which are critical for producing new carbide products. This recycling process not only conserves these valuable resources but also reduces the environmental impact associated with mining and processing new materials. Titanium Carbide, on the other hand, is known for its high hardness and thermal conductivity. It is often used in applications that require resistance to wear and high temperatures, such as in the aerospace and automotive industries. Recycling TiC involves recovering titanium and other valuable metals, which can be reused in the production of new carbide products. This process helps in reducing the reliance on virgin raw materials and supports sustainable manufacturing practices. Tantalum Carbide is prized for its high melting point and excellent chemical resistance, making it suitable for applications in the electronics and aerospace industries. Recycling TaC involves recovering tantalum, a rare and valuable metal, which can be reused in the production of new carbide products. The recycling of tantalum carbide not only conserves this scarce resource but also reduces the environmental impact associated with its extraction and processing. The Global Cemented Carbide Recycling Market plays a crucial role in recovering these valuable materials, contributing to resource conservation and environmental sustainability. As industries continue to prioritize sustainable practices, the demand for recycling tungsten carbide, titanium carbide, and tantalum carbide is expected to grow, supporting the development of a more circular economy.

Cutting Tools, Mining Tools, Wear Resistant Appliances, Others in the Global Cemented Carbide Recycling Market:

The Global Cemented Carbide Recycling Market finds extensive usage in various areas, including cutting tools, mining tools, wear-resistant appliances, and others. In the realm of cutting tools, cemented carbide materials are highly valued for their ability to maintain sharpness and resist wear, even under extreme conditions. This makes them ideal for use in industries such as metalworking, woodworking, and machining, where precision and durability are paramount. Recycling cemented carbide cutting tools involves recovering valuable materials like tungsten and cobalt, which can be reused in the production of new tools, thereby reducing the demand for virgin raw materials and minimizing environmental impact. In the mining industry, cemented carbide materials are used in the production of mining tools such as drill bits and cutting inserts. These tools are subjected to harsh conditions and require exceptional hardness and wear resistance to perform effectively. Recycling mining tools made from cemented carbide helps in recovering valuable metals, which can be reused in the production of new tools, supporting sustainable mining practices and reducing the environmental footprint associated with mining operations. Wear-resistant appliances, such as those used in the manufacturing and construction industries, also benefit from the use of cemented carbide materials. These appliances require materials that can withstand abrasion and wear over extended periods, making cemented carbide an ideal choice. Recycling wear-resistant appliances involves recovering valuable materials that can be reused in the production of new appliances, contributing to resource conservation and environmental sustainability. Other areas where the Global Cemented Carbide Recycling Market finds application include the electronics and aerospace industries, where cemented carbide materials are used in the production of components that require high hardness and resistance to wear and corrosion. Recycling these components helps in recovering valuable materials that can be reused in the production of new components, supporting sustainable manufacturing practices and reducing the environmental impact associated with the extraction and processing of raw materials. As industries continue to prioritize sustainability and resource conservation, the demand for cemented carbide recycling is expected to grow, supporting the development of a more circular economy.

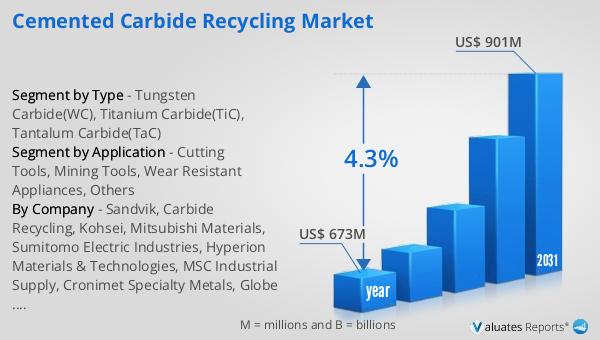

Global Cemented Carbide Recycling Market Outlook:

The global market for Cemented Carbide Recycling was valued at $673 million in 2024 and is anticipated to expand to a revised size of $901 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period. This growth trajectory underscores the increasing recognition of the economic and environmental benefits associated with recycling cemented carbide materials. As industries across the globe strive to adopt more sustainable practices, the demand for recycled materials is on the rise. Cemented carbide recycling not only helps in conserving valuable resources like tungsten and cobalt but also significantly reduces the environmental impact associated with mining and processing new materials. The market's growth is further fueled by advancements in recycling technologies, which have made the recovery of these materials more efficient and cost-effective. Additionally, the growing awareness about the importance of reducing carbon footprints and promoting a circular economy is driving industries to invest in recycling initiatives. As a result, the Global Cemented Carbide Recycling Market is poised for steady growth, offering significant opportunities for businesses and stakeholders involved in the recycling industry. This market outlook highlights the potential for continued expansion and innovation in the field of cemented carbide recycling, contributing to a more sustainable and resource-efficient future.

| Report Metric | Details |

| Report Name | Cemented Carbide Recycling Market |

| Accounted market size in year | US$ 673 million |

| Forecasted market size in 2031 | US$ 901 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sandvik, Carbide Recycling, Kohsei, Mitsubishi Materials, Sumitomo Electric Industries, Hyperion Materials & Technologies, MSC Industrial Supply, Cronimet Specialty Metals, Globe Metal, SECO Tools AB, Kennametal, A.L.M.T. Corp., GEM, Toyota, BETEK, Ceratizit, Saar-Hartmetall, Dormer Pramet, H.C. Starck Tungsten Powders |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |