What is Global Burners NOx Control Systems Market?

The Global Burners NOx Control Systems Market is a specialized segment within the broader environmental technology industry, focusing on reducing nitrogen oxides (NOx) emissions from combustion processes. NOx is a significant pollutant contributing to smog, acid rain, and respiratory problems, making its control crucial for environmental and public health. Burners NOx Control Systems are designed to minimize these emissions in various applications, including industrial, transportation, and energy sectors. These systems employ advanced technologies to optimize combustion processes, ensuring that NOx emissions are kept within regulatory limits. The market for these systems is driven by stringent environmental regulations, technological advancements, and the increasing awareness of the environmental impact of NOx emissions. As industries strive to meet regulatory requirements and reduce their environmental footprint, the demand for effective NOx control solutions continues to grow. This market is characterized by a range of technologies, including low NOx burners, selective catalytic reduction (SCR), and selective non-catalytic reduction (SNCR), each offering different levels of efficiency and applicability depending on the specific requirements of the application.

Selective Non-Catalytic Reduction (SNCR) Reaction, Selective Catalytic Reduction (SCR) Reaction in the Global Burners NOx Control Systems Market:

Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR) are two prominent technologies used in the Global Burners NOx Control Systems Market to mitigate nitrogen oxides emissions. SNCR is a process that involves injecting a reagent, such as ammonia or urea, into the combustion gases at high temperatures. This reaction occurs without the need for a catalyst, making it a cost-effective solution for reducing NOx emissions. The SNCR process is typically applied in industrial boilers, waste incinerators, and power plants where the temperature conditions are suitable for the reaction to occur. The effectiveness of SNCR depends on factors such as temperature, residence time, and the distribution of the reagent, with typical NOx reduction efficiencies ranging from 30% to 70%. On the other hand, SCR is a more advanced technology that uses a catalyst to facilitate the reaction between NOx and a reducing agent, usually ammonia, to form nitrogen and water. This process is highly efficient, achieving NOx reduction rates of up to 90% or more. SCR systems are widely used in power plants, industrial facilities, and transportation applications, where stringent NOx emission limits are in place. The catalyst in SCR systems is typically made of materials such as vanadium, titanium, or zeolites, which enhance the reaction at lower temperatures compared to SNCR. The choice between SNCR and SCR depends on various factors, including the specific emission reduction requirements, cost considerations, and the operational conditions of the facility. While SCR offers higher efficiency, it is generally more expensive due to the cost of the catalyst and the need for precise control of the reaction conditions. In contrast, SNCR is simpler and less costly but may not achieve the same level of NOx reduction as SCR. Both technologies play a crucial role in the Global Burners NOx Control Systems Market, providing industries with options to meet regulatory requirements and reduce their environmental impact. As environmental regulations become more stringent, the demand for effective NOx control solutions is expected to increase, driving innovation and advancements in both SNCR and SCR technologies.

Transportation, Industrial, Energy, Others in the Global Burners NOx Control Systems Market:

The Global Burners NOx Control Systems Market finds applications across various sectors, including transportation, industrial, energy, and others, each with unique requirements and challenges. In the transportation sector, NOx control systems are essential for reducing emissions from vehicles, particularly diesel engines, which are significant contributors to NOx pollution. Technologies such as SCR are commonly used in vehicles to meet stringent emission standards, ensuring that NOx emissions are minimized while maintaining engine performance. The industrial sector also relies heavily on NOx control systems to comply with environmental regulations and reduce the environmental impact of manufacturing processes. Industries such as cement, steel, and chemical manufacturing often use burners NOx control systems to optimize combustion processes and minimize emissions. In the energy sector, power plants are significant sources of NOx emissions, making NOx control systems critical for reducing their environmental footprint. Both SNCR and SCR technologies are widely used in power plants to achieve compliance with emission limits and improve air quality. Additionally, other sectors, such as waste management and food processing, also utilize NOx control systems to address specific emission challenges and meet regulatory requirements. The versatility and effectiveness of burners NOx control systems make them indispensable tools for industries seeking to reduce their environmental impact and comply with increasingly stringent emission standards. As awareness of the environmental and health impacts of NOx emissions grows, the demand for advanced NOx control solutions is expected to rise, driving innovation and development in the Global Burners NOx Control Systems Market.

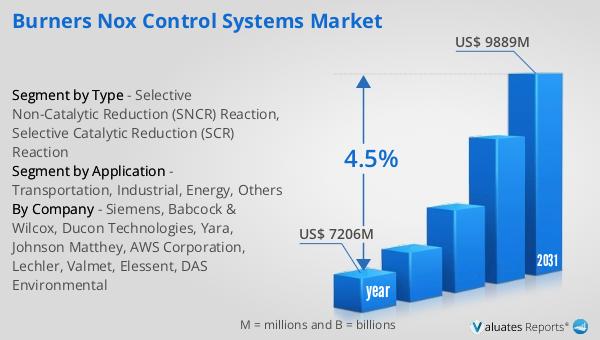

Global Burners NOx Control Systems Market Outlook:

In 2024, the global market for Burners NOx Control Systems was valued at approximately US$ 7,206 million. This market is anticipated to expand significantly, reaching an estimated size of US$ 9,889 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The increasing demand for effective NOx control solutions across various industries is a key driver of this market growth. As environmental regulations become more stringent and industries strive to reduce their environmental impact, the adoption of advanced NOx control technologies is expected to rise. The market's expansion is also supported by technological advancements and the development of more efficient and cost-effective NOx control systems. As industries continue to prioritize sustainability and compliance with emission standards, the Global Burners NOx Control Systems Market is poised for continued growth and innovation. This market outlook highlights the significant opportunities for companies operating in this space to capitalize on the growing demand for NOx control solutions and contribute to a cleaner and more sustainable future.

| Report Metric | Details |

| Report Name | Burners NOx Control Systems Market |

| Accounted market size in year | US$ 7206 million |

| Forecasted market size in 2031 | US$ 9889 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens, Babcock & Wilcox, Ducon Technologies, Yara, Johnson Matthey, AWS Corporation, Lechler, Valmet, Elessent, DAS Environmental |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |