What is Global Automated Optical Inspection Machine Market?

The Global Automated Optical Inspection (AOI) Machine Market is a rapidly evolving sector that plays a crucial role in quality control across various industries. AOI machines are used to automatically inspect and analyze products for defects during the manufacturing process. These machines utilize advanced optical systems and software algorithms to detect flaws that might be missed by human inspectors. The global market for AOI machines is driven by the increasing demand for high-quality products and the need for efficient inspection processes. As industries continue to automate their production lines, the adoption of AOI machines is expected to grow. These machines are particularly valuable in sectors where precision and reliability are paramount, such as electronics, automotive, and aerospace. By reducing the reliance on manual inspection, AOI machines help manufacturers improve product quality, reduce waste, and increase production efficiency. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more sophisticated and versatile AOI systems. As a result, the Global Automated Optical Inspection Machine Market is poised for significant growth in the coming years, driven by the need for enhanced quality control and the ongoing trend towards automation in manufacturing processes.

Online Automated Optical Inspection Machine, Offline Automated Optical Inspection Machine in the Global Automated Optical Inspection Machine Market:

In the realm of Automated Optical Inspection Machines, there are two primary types: Online and Offline AOI machines. Online AOI machines are integrated directly into the production line, allowing for real-time inspection of products as they are manufactured. This integration enables immediate detection and correction of defects, minimizing the risk of defective products reaching the end of the production line. Online AOI systems are particularly beneficial in high-speed manufacturing environments where rapid inspection is essential to maintain production flow. These systems are equipped with high-speed cameras and advanced image processing software to quickly identify defects such as misalignments, missing components, or surface blemishes. On the other hand, Offline AOI machines are used for batch inspection, where products are inspected separately from the production line. This type of AOI system is ideal for smaller production runs or for inspecting products that require more detailed analysis. Offline AOI machines offer greater flexibility in terms of inspection criteria and can be used to perform more comprehensive inspections that might not be feasible in an online setting. Both Online and Offline AOI machines play a vital role in ensuring product quality and consistency, but they cater to different manufacturing needs. Online AOI systems are best suited for high-volume production environments where speed and efficiency are critical, while Offline AOI systems are more appropriate for detailed inspections and smaller production batches. The choice between Online and Offline AOI machines depends on various factors, including the nature of the product, production volume, and specific quality control requirements. As the Global Automated Optical Inspection Machine Market continues to grow, manufacturers are increasingly adopting both types of AOI systems to enhance their quality control processes and meet the demands of a competitive market.

Flat Panel Displays, Printed Circuit Boards, Semiconductors, Others in the Global Automated Optical Inspection Machine Market:

The Global Automated Optical Inspection Machine Market finds extensive application across several key areas, including Flat Panel Displays, Printed Circuit Boards (PCBs), Semiconductors, and other sectors. In the Flat Panel Display industry, AOI machines are used to inspect the quality of display panels, ensuring that they are free from defects such as dead pixels, color inconsistencies, or surface scratches. The precision and accuracy of AOI systems are crucial in this sector, as even minor defects can significantly impact the performance and visual quality of display panels. In the realm of Printed Circuit Boards, AOI machines are indispensable for inspecting the intricate patterns and connections that make up a PCB. These machines can quickly identify issues such as soldering defects, component misplacements, or short circuits, which are critical to the functionality of electronic devices. The use of AOI machines in PCB inspection helps manufacturers maintain high standards of quality and reliability, reducing the risk of product failures. In the Semiconductor industry, AOI machines are employed to inspect wafers and chips for defects that could affect their performance. Given the complexity and miniaturization of semiconductor components, AOI systems must be highly sophisticated to detect minute defects that could compromise the functionality of the final product. Beyond these specific industries, AOI machines are also used in other sectors such as automotive, aerospace, and medical devices, where precision and reliability are paramount. In the automotive industry, for example, AOI systems are used to inspect components such as engine parts, electronic modules, and safety systems to ensure they meet stringent quality standards. Similarly, in the aerospace sector, AOI machines are used to inspect critical components that must adhere to rigorous safety and performance criteria. The versatility and adaptability of AOI machines make them an essential tool in various industries, contributing to improved product quality, reduced waste, and enhanced production efficiency.

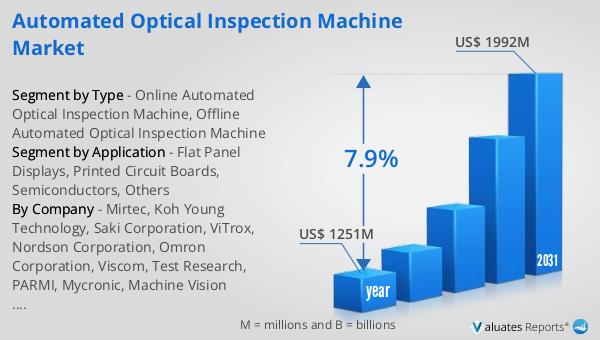

Global Automated Optical Inspection Machine Market Outlook:

The global market for Automated Optical Inspection Machines was valued at $1,251 million in 2024 and is anticipated to expand to a revised size of $1,992 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.9% over the forecast period. This growth trajectory underscores the increasing importance of AOI machines in modern manufacturing processes. As industries strive to enhance product quality and streamline production, the demand for efficient and reliable inspection solutions is on the rise. AOI machines offer a compelling solution by providing automated, high-speed inspection capabilities that can significantly reduce the likelihood of defects in the final product. The projected growth of the AOI market is driven by several factors, including the ongoing trend towards automation, the need for higher quality standards, and the rapid advancements in AOI technology. Manufacturers are increasingly recognizing the value of AOI systems in improving production efficiency and reducing costs associated with product recalls and rework. As a result, the adoption of AOI machines is expected to continue its upward trajectory, with more industries integrating these systems into their quality control processes. The market outlook for AOI machines is promising, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Automated Optical Inspection Machine Market |

| Accounted market size in year | US$ 1251 million |

| Forecasted market size in 2031 | US$ 1992 million |

| CAGR | 7.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type | |

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mirtec, Koh Young Technology, Saki Corporation, ViTrox, Nordson Corporation, Omron Corporation, Viscom, Test Research, PARMI, Mycronic, Machine Vision Products (MVP), Mek (Marantz Electronics), Pemtron, JUTZE, Suzhou CIMS Automation Equipment, Machvision, Orbotech, Takano, Utechzone, Wuhan Jingce Electronic Group, ZhenHuaXing Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |