What is Global Robot Palletizing System Market?

The Global Robot Palletizing System Market refers to the worldwide industry focused on the development, production, and sale of robotic systems designed to automate the process of stacking and organizing products onto pallets. These systems are crucial in various industries as they enhance efficiency, reduce labor costs, and improve workplace safety by minimizing the need for manual handling of heavy or repetitive tasks. The market encompasses a range of technologies and solutions, including fully-automatic and semi-automatic systems, tailored to meet the diverse needs of industries such as food and beverage, consumer goods, and industrial manufacturing. As businesses increasingly seek to optimize their supply chains and production processes, the demand for robot palletizing systems is expected to grow. These systems not only streamline operations but also offer flexibility and scalability, allowing companies to adapt to changing production demands and market conditions. The market is characterized by continuous innovation, with manufacturers investing in advanced technologies such as artificial intelligence and machine learning to enhance the capabilities of palletizing robots. This ongoing development is expected to drive further adoption across various sectors, contributing to the market's expansion.

Fully-automatic Type, Semi-automatic Type in the Global Robot Palletizing System Market:

In the Global Robot Palletizing System Market, systems are generally categorized into two main types: fully-automatic and semi-automatic. Fully-automatic palletizing systems are designed to operate with minimal human intervention. These systems are equipped with advanced sensors, software, and robotic arms that can handle complex tasks such as identifying, picking, and placing products onto pallets with high precision and speed. They are ideal for high-volume production environments where efficiency and accuracy are paramount. Fully-automatic systems can be integrated into existing production lines, offering seamless operation and reducing the need for manual labor. They are often used in industries where consistency and speed are critical, such as in large-scale manufacturing and distribution centers. On the other hand, semi-automatic palletizing systems require some level of human involvement. While they also use robotic technology to assist with the palletizing process, operators are needed to oversee the operation, manage inputs, and occasionally intervene in the process. These systems are typically more cost-effective than fully-automatic systems and are suitable for smaller operations or businesses with lower production volumes. Semi-automatic systems offer flexibility and can be a stepping stone for companies looking to transition from manual to automated processes. Both types of systems have their advantages and are chosen based on the specific needs and resources of a business. Fully-automatic systems, while more expensive, provide higher throughput and efficiency, making them a worthwhile investment for large-scale operations. Semi-automatic systems, however, offer a balance between automation and human oversight, making them accessible to a wider range of businesses. As technology advances, the line between these two types of systems is becoming increasingly blurred, with semi-automatic systems incorporating more automated features and fully-automatic systems becoming more user-friendly. This evolution is driven by the need for businesses to remain competitive and responsive to market demands. The choice between fully-automatic and semi-automatic systems ultimately depends on factors such as budget, production volume, and the level of automation desired. Companies must carefully assess their operational needs and long-term goals to determine the most suitable solution. As the Global Robot Palletizing System Market continues to grow, both fully-automatic and semi-automatic systems will play a crucial role in shaping the future of industrial automation.

Food & Beverage, Consumer Goods, Industrial, Others in the Global Robot Palletizing System Market:

The Global Robot Palletizing System Market finds extensive application across various sectors, including food and beverage, consumer goods, industrial, and others. In the food and beverage industry, robot palletizing systems are used to handle a wide range of products, from packaged foods and beverages to raw ingredients. These systems help streamline the packaging and distribution process, ensuring that products are efficiently stacked and organized for transportation. The use of robotic palletizers in this sector not only enhances productivity but also maintains hygiene standards by reducing human contact with food products. In the consumer goods industry, robot palletizing systems are employed to manage the packaging and distribution of a diverse array of products, including electronics, clothing, and household items. These systems enable companies to optimize their supply chains by automating the palletizing process, reducing the time and labor required to prepare products for shipment. This automation is particularly beneficial in meeting the demands of e-commerce, where speed and accuracy are crucial. In the industrial sector, robot palletizing systems are used to handle heavy and bulky items, such as machinery parts and construction materials. These systems improve workplace safety by minimizing the need for manual lifting and handling of heavy objects, reducing the risk of workplace injuries. Additionally, they enhance operational efficiency by ensuring that products are accurately and consistently stacked, ready for transport or further processing. Beyond these primary sectors, robot palletizing systems are also utilized in other industries, such as pharmaceuticals and chemicals, where precision and reliability are essential. In these applications, robotic systems help maintain the integrity of products by ensuring they are handled with care and precision. The versatility of robot palletizing systems makes them an invaluable asset across various industries, enabling companies to improve efficiency, reduce costs, and enhance overall productivity. As the demand for automation continues to rise, the Global Robot Palletizing System Market is poised for significant growth, driven by the need for efficient and reliable solutions across diverse sectors.

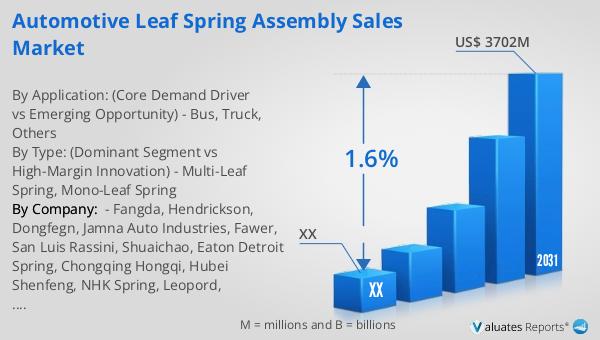

Global Robot Palletizing System Market Outlook:

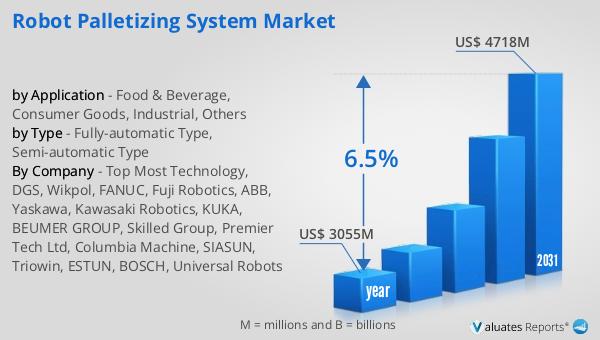

The global market for Robot Palletizing Systems was valued at approximately $3,055 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $4,718 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.5% over the forecast period. The increasing adoption of automation in various industries is a key driver of this market expansion. As businesses strive to enhance operational efficiency and reduce labor costs, the demand for robotic palletizing systems is expected to rise. These systems offer numerous benefits, including improved accuracy, speed, and safety in handling and organizing products. The market's growth is also fueled by advancements in technology, such as the integration of artificial intelligence and machine learning, which enhance the capabilities of robotic systems. These innovations enable robots to perform more complex tasks with greater precision, further driving their adoption across different sectors. Additionally, the growing trend of e-commerce and the need for efficient supply chain management are contributing to the increased demand for robot palletizing systems. As companies seek to optimize their logistics and distribution processes, the use of automated solutions becomes increasingly essential. The market's positive outlook is supported by the continuous efforts of manufacturers to develop innovative and cost-effective solutions that cater to the evolving needs of businesses. As a result, the Global Robot Palletizing System Market is expected to witness sustained growth, offering significant opportunities for industry players and stakeholders.

| Report Metric | Details |

| Report Name | Robot Palletizing System Market |

| Accounted market size in year | US$ 3055 million |

| Forecasted market size in 2031 | US$ 4718 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Top Most Technology, DGS, Wikpol, FANUC, Fuji Robotics, ABB, Yaskawa, Kawasaki Robotics, KUKA, BEUMER GROUP, Skilled Group, Premier Tech Ltd, Columbia Machine, SIASUN, Triowin, ESTUN, BOSCH, Universal Robots |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |