What is Global Lithium Battery Laminating Machines Market?

The Global Lithium Battery Laminating Machines Market is a specialized segment within the broader machinery and equipment industry, focusing on the production of laminating machines specifically designed for lithium batteries. These machines play a crucial role in the manufacturing process of lithium batteries, which are widely used in various applications due to their high energy density, lightweight, and long lifespan. The market for these machines is driven by the increasing demand for lithium batteries, particularly in sectors such as electric vehicles, consumer electronics, and renewable energy storage systems. As the world shifts towards more sustainable energy solutions, the need for efficient and high-quality lithium battery production becomes paramount, thereby boosting the demand for advanced laminating machines. These machines are essential for ensuring the structural integrity and performance of lithium batteries by precisely layering the battery components, which include electrodes and separators. The market is characterized by technological advancements aimed at improving the efficiency, speed, and precision of laminating processes, catering to the evolving needs of battery manufacturers. As a result, the Global Lithium Battery Laminating Machines Market is poised for significant growth, driven by innovation and the expanding application of lithium batteries across various industries.

Z-type Laminating Type, Cutting and Laminating Type, Thermal Laminating Type, Rolling and Laminating Type in the Global Lithium Battery Laminating Machines Market:

In the Global Lithium Battery Laminating Machines Market, several types of laminating machines are utilized, each with distinct features and applications. The Z-type Laminating Type is known for its unique zigzag pattern, which enhances the structural stability of the laminated layers. This type is particularly beneficial in applications where mechanical strength and durability are critical. The Z-type laminating machines are designed to handle high-speed operations, making them suitable for large-scale production environments. They are equipped with advanced control systems that ensure precise alignment and uniform pressure distribution across the layers, resulting in high-quality laminates that meet stringent industry standards.

Electric Vehicles, Energy Storage, Consumer Electronics, Medical, Others in the Global Lithium Battery Laminating Machines Market:

The Cutting and Laminating Type machines combine the processes of cutting and laminating in a single operation, streamlining the production process and reducing the need for multiple machines. This integration not only saves space but also enhances operational efficiency by minimizing material handling and reducing cycle times. These machines are equipped with sophisticated cutting mechanisms that ensure clean and accurate cuts, which are essential for maintaining the integrity of the battery components. The laminating process in these machines is highly controlled, with adjustable parameters that allow manufacturers to customize the laminates according to specific requirements. This flexibility makes the Cutting and Laminating Type machines ideal for producing a wide range of battery sizes and configurations.

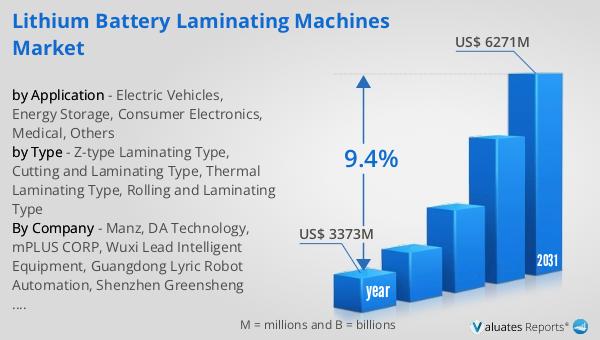

Global Lithium Battery Laminating Machines Market Outlook:

Thermal Laminating Type machines utilize heat to bond the layers of the battery components together. This method is particularly effective for materials that require a strong adhesive bond, as the heat activates the adhesive properties of the laminating materials. Thermal laminating machines are designed to operate at various temperature settings, allowing manufacturers to optimize the bonding process for different materials and thicknesses. These machines are equipped with advanced temperature control systems that ensure consistent heat distribution, preventing overheating and ensuring the quality of the laminates. The thermal laminating process is known for its ability to produce durable and long-lasting laminates, making it a preferred choice for applications where reliability is paramount.

| Report Metric | Details |

| Report Name | Lithium Battery Laminating Machines Market |

| Accounted market size in year | US$ 3373 million |

| Forecasted market size in 2031 | US$ 6271 million |

| CAGR | 9.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Manz, DA Technology, mPLUS CORP, Wuxi Lead Intelligent Equipment, Guangdong Lyric Robot Automation, Shenzhen Greensheng Technology, Geesun Intelligent Technology, Shenzhen Colibri Technologies, Shenzhen Yinghe Technology, Haimuxing Laser Technology, Yingfukang Industrial Technology, Chaoye Precision Equipment (Funeng Oriental Equipment Technology), Kejing STAR Technology, Fenghesheng Intelligent Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |