What is Global Shaft Lifting Wire Rope Market?

The Global Shaft Lifting Wire Rope Market is a specialized segment within the broader wire rope industry, focusing on ropes used specifically for lifting applications in various sectors. These wire ropes are crucial components in machinery and equipment that require the lifting and lowering of heavy loads, such as elevators, cranes, and hoists. The market is driven by the demand for efficient and reliable lifting solutions in industries like construction, mining, and manufacturing. Shaft lifting wire ropes are designed to withstand high tension and stress, ensuring safety and durability in operations. They are typically made from high-strength steel and may be coated or treated to enhance their performance and longevity. The market is influenced by factors such as technological advancements, increasing industrialization, and the need for improved safety standards. As industries continue to expand and modernize, the demand for high-quality shaft lifting wire ropes is expected to grow, making this market a vital component of the global industrial landscape. Companies operating in this market focus on innovation and quality to meet the evolving needs of their customers, ensuring that their products can handle the rigorous demands of modern lifting applications.

Galvanizing, Polymer Coating, Others in the Global Shaft Lifting Wire Rope Market:

Galvanizing, polymer coating, and other treatments play a significant role in the Global Shaft Lifting Wire Rope Market, enhancing the performance and durability of wire ropes used in various applications. Galvanizing is a process where a protective zinc coating is applied to steel wire ropes to prevent rusting. This process is crucial for wire ropes used in outdoor or harsh environments, where exposure to moisture and other corrosive elements is common. Galvanized wire ropes are known for their longevity and resistance to environmental degradation, making them ideal for use in construction, mining, and marine applications. The zinc coating acts as a barrier, protecting the steel core from corrosion and extending the rope's service life. Polymer coating, on the other hand, involves applying a layer of polymer material over the wire rope. This coating provides additional protection against abrasion, chemical exposure, and environmental factors. Polymer-coated wire ropes are often used in applications where the rope is subjected to frequent contact with abrasive surfaces or chemicals, such as in industrial machinery or chemical plants. The polymer layer not only protects the steel core but also reduces friction, enhancing the rope's performance and efficiency. Other treatments in the shaft lifting wire rope market include lubrication and heat treatment. Lubrication involves applying a lubricant to the wire rope to reduce friction and wear between the individual wires and strands. This process is essential for maintaining the rope's flexibility and preventing premature failure due to metal fatigue. Heat treatment, on the other hand, involves heating the wire rope to a specific temperature and then cooling it to alter its physical properties. This process can enhance the rope's strength, flexibility, and resistance to wear and tear. In addition to these treatments, manufacturers in the shaft lifting wire rope market are continually exploring new materials and technologies to improve the performance and durability of their products. For example, some companies are experimenting with advanced coatings that offer superior protection against corrosion and abrasion, while others are developing new wire rope designs that optimize strength and flexibility. These innovations are driven by the increasing demand for high-performance wire ropes in industries such as construction, mining, and oil and gas, where safety and reliability are paramount. As the global economy continues to grow and industrial activities expand, the demand for shaft lifting wire ropes with enhanced performance characteristics is expected to rise. This trend is likely to drive further innovation and development in the market, as manufacturers strive to meet the evolving needs of their customers. Overall, galvanizing, polymer coating, and other treatments are essential components of the Global Shaft Lifting Wire Rope Market, ensuring that wire ropes can withstand the demanding conditions of modern industrial applications.

Mining, Underground Engineering, Others in the Global Shaft Lifting Wire Rope Market:

The Global Shaft Lifting Wire Rope Market finds extensive usage in various sectors, including mining, underground engineering, and other industries that require reliable lifting solutions. In the mining industry, shaft lifting wire ropes are essential for transporting materials and personnel between the surface and underground mining sites. These ropes are designed to withstand the harsh conditions of mining environments, including exposure to dust, moisture, and heavy loads. The durability and strength of shaft lifting wire ropes make them ideal for use in mining operations, where safety and efficiency are critical. In underground engineering, shaft lifting wire ropes are used in the construction and maintenance of tunnels, subways, and other subterranean structures. These ropes are crucial for lifting and lowering construction materials, equipment, and workers in confined spaces. The ability of shaft lifting wire ropes to handle heavy loads and resist wear and tear makes them indispensable in underground engineering projects. Additionally, the use of advanced coatings and treatments ensures that these ropes can withstand the challenging conditions of underground environments, such as high humidity and corrosive elements. Beyond mining and underground engineering, shaft lifting wire ropes are also used in various other industries, including construction, manufacturing, and transportation. In construction, these ropes are used in cranes and hoists to lift and move heavy materials, such as steel beams and concrete blocks. The strength and reliability of shaft lifting wire ropes make them essential for ensuring the safety and efficiency of construction operations. In manufacturing, these ropes are used in machinery and equipment that require precise lifting and positioning of components. The ability of shaft lifting wire ropes to handle repetitive lifting tasks without compromising performance makes them ideal for use in automated manufacturing processes. In the transportation industry, shaft lifting wire ropes are used in elevators and escalators to transport passengers and goods between different levels of buildings. The safety and reliability of these ropes are paramount in ensuring the smooth operation of vertical transportation systems. Overall, the Global Shaft Lifting Wire Rope Market plays a vital role in supporting various industries by providing reliable and efficient lifting solutions. The versatility and durability of shaft lifting wire ropes make them indispensable in applications where safety, efficiency, and performance are critical. As industries continue to evolve and expand, the demand for high-quality shaft lifting wire ropes is expected to grow, driving further innovation and development in the market.

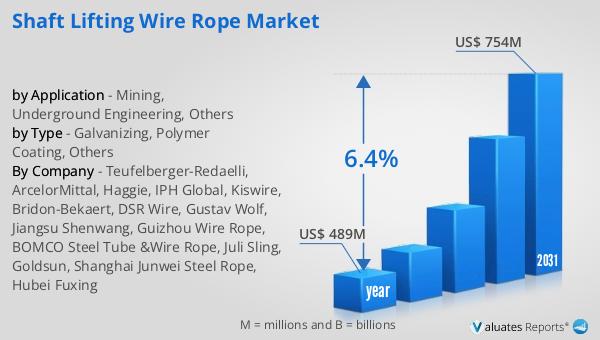

Global Shaft Lifting Wire Rope Market Outlook:

The global market for Shaft Lifting Wire Rope was valued at $489 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $754 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.4% over the forecast period. This upward trend in the market is indicative of the increasing demand for shaft lifting wire ropes across various industries, driven by the need for efficient and reliable lifting solutions. The market's growth can be attributed to several factors, including the expansion of industrial activities, advancements in technology, and the implementation of stringent safety standards. As industries such as construction, mining, and manufacturing continue to grow, the demand for high-quality shaft lifting wire ropes is expected to rise. Companies operating in this market are focusing on innovation and quality to meet the evolving needs of their customers, ensuring that their products can handle the rigorous demands of modern lifting applications. The projected growth of the Global Shaft Lifting Wire Rope Market highlights the importance of these products in supporting industrial activities and underscores the need for continued investment in research and development to enhance their performance and durability.

| Report Metric | Details |

| Report Name | Shaft Lifting Wire Rope Market |

| Accounted market size in year | US$ 489 million |

| Forecasted market size in 2031 | US$ 754 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teufelberger-Redaelli, ArcelorMittal, Haggie, IPH Global, Kiswire, Bridon-Bekaert, DSR Wire, Gustav Wolf, Jiangsu Shenwang, Guizhou Wire Rope, BOMCO Steel Tube &Wire Rope, Juli Sling, Goldsun, Shanghai Junwei Steel Rope, Hubei Fuxing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |