What is Global Compensation Wire Rope Market?

The Global Compensation Wire Rope Market is a specialized segment within the broader wire rope industry, focusing on ropes used primarily for balancing and compensating purposes in various mechanical systems. These ropes are essential in applications where precise weight distribution and tension management are critical, such as in elevators, cranes, and other lifting equipment. The market is driven by the increasing demand for efficient and reliable lifting solutions across various industries, including construction, mining, and transportation. As urbanization and industrialization continue to rise globally, the need for advanced infrastructure and efficient material handling systems has become more pronounced, further propelling the demand for compensation wire ropes. These ropes are designed to withstand significant stress and strain, ensuring safety and longevity in their applications. The market is characterized by a diverse range of products, including ropes with different core materials and coatings, each offering unique benefits in terms of strength, flexibility, and corrosion resistance. As technology advances, manufacturers are continually innovating to improve the performance and durability of these ropes, catering to the evolving needs of their customers. The global compensation wire rope market is poised for steady growth, driven by technological advancements and the increasing emphasis on safety and efficiency in industrial operations.

Galvanized Steel Core, Fiber Core, Others in the Global Compensation Wire Rope Market:

In the Global Compensation Wire Rope Market, the choice of core material is crucial as it significantly influences the rope's performance, durability, and suitability for specific applications. One of the most common core types is the Galvanized Steel Core. This type of core is favored for its exceptional strength and resistance to environmental factors such as moisture and corrosion. Galvanization involves coating the steel with a layer of zinc, which acts as a protective barrier against rust and wear. This makes galvanized steel core ropes ideal for outdoor applications or environments where the rope is exposed to harsh weather conditions. They are particularly popular in industries like construction and marine, where durability and longevity are paramount. The strength of the steel core also ensures that the rope can handle heavy loads and high tension, making it suitable for demanding applications such as cranes and elevators. On the other hand, Fiber Core ropes are known for their flexibility and ease of handling. The core is typically made from natural or synthetic fibers, which provide a softer and more pliable structure compared to steel cores. This flexibility makes fiber core ropes easier to work with, especially in applications where the rope needs to bend or wrap around pulleys and sheaves. However, fiber cores are generally less durable than steel cores and may not be suitable for extremely heavy loads or harsh environments. They are often used in applications where the rope's ability to absorb shock and reduce vibration is more important than its load-bearing capacity. For instance, fiber core ropes are commonly used in elevators and other lifting equipment where smooth and quiet operation is desired. Apart from galvanized steel and fiber cores, there are other core materials used in the compensation wire rope market, each offering distinct advantages. For example, some ropes feature a combination of steel and fiber cores, providing a balance between strength and flexibility. These hybrid cores are designed to offer the best of both worlds, making them suitable for a wide range of applications. Additionally, advancements in material science have led to the development of synthetic cores made from high-performance polymers. These synthetic cores are lightweight, resistant to corrosion, and can offer superior strength-to-weight ratios compared to traditional materials. They are increasingly being adopted in industries where weight reduction is a critical factor, such as aerospace and automotive. The choice of core material in compensation wire ropes is often dictated by the specific requirements of the application, including load capacity, environmental conditions, and operational demands. Manufacturers in the global compensation wire rope market continue to innovate and develop new materials and technologies to enhance the performance and durability of their products. As industries evolve and new challenges emerge, the demand for specialized wire ropes with tailored properties is expected to grow, driving further advancements in core materials and rope design.

Elevator, Lifting Equipment, Others in the Global Compensation Wire Rope Market:

The Global Compensation Wire Rope Market finds extensive usage in various sectors, with elevators and lifting equipment being among the most prominent. In the elevator industry, compensation wire ropes play a critical role in ensuring smooth and efficient operation. These ropes are used to balance the weight of the elevator car and counterweight, reducing the load on the motor and improving energy efficiency. The use of compensation ropes in elevators also enhances ride comfort by minimizing vibrations and noise. As urbanization continues to drive the construction of high-rise buildings, the demand for reliable and efficient elevator systems is on the rise, further boosting the market for compensation wire ropes. In the realm of lifting equipment, compensation wire ropes are indispensable for ensuring safety and performance. They are used in cranes, hoists, and other lifting devices to manage the distribution of weight and tension, preventing accidents and equipment failure. The strength and durability of these ropes are crucial in handling heavy loads and withstanding the rigors of industrial environments. As industries such as construction, mining, and logistics continue to expand, the need for advanced lifting solutions is becoming increasingly important, driving the demand for high-quality compensation wire ropes. Beyond elevators and lifting equipment, compensation wire ropes are also used in a variety of other applications. For instance, they are employed in cable cars and funiculars, where they help balance the weight of the cars and ensure smooth operation. In the maritime industry, these ropes are used in mooring and towing applications, where their strength and resistance to corrosion are essential. Additionally, compensation wire ropes are used in the entertainment industry for stage rigging and special effects, where precise control and reliability are paramount. The versatility and reliability of compensation wire ropes make them a vital component in numerous industries. As technology advances and new applications emerge, the demand for these ropes is expected to grow, driving further innovation and development in the market. Manufacturers are continually exploring new materials and designs to enhance the performance and durability of their products, ensuring they meet the evolving needs of their customers. The global compensation wire rope market is poised for steady growth, driven by the increasing emphasis on safety, efficiency, and performance in industrial operations.

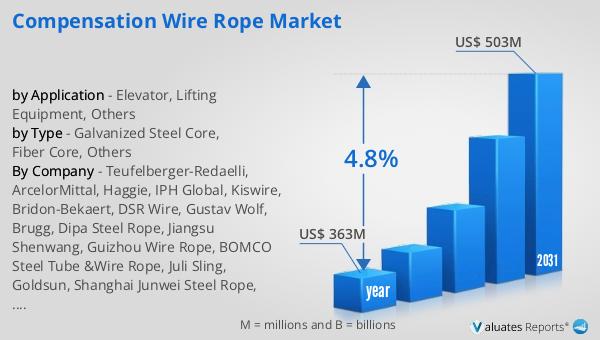

Global Compensation Wire Rope Market Outlook:

In 2024, the global market for Compensation Wire Rope was valued at approximately $363 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $503 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.8% during the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for efficient and reliable lifting solutions across various industries. As urbanization and industrialization continue to accelerate globally, the need for advanced infrastructure and material handling systems has become more pronounced, further driving the demand for compensation wire ropes. The market's growth is also supported by technological advancements and innovations in wire rope design and materials. Manufacturers are continually developing new products with enhanced performance characteristics, such as increased strength, flexibility, and corrosion resistance, to meet the evolving needs of their customers. Additionally, the increasing emphasis on safety and efficiency in industrial operations is driving the adoption of high-quality compensation wire ropes. As industries such as construction, mining, and transportation continue to expand, the demand for reliable and durable wire ropes is expected to grow, contributing to the market's overall growth. Overall, the global compensation wire rope market is poised for steady growth, driven by the increasing demand for advanced lifting solutions and the ongoing development of new technologies and materials. As the market continues to evolve, manufacturers will need to stay ahead of the curve by investing in research and development and exploring new opportunities for innovation and expansion.

| Report Metric | Details |

| Report Name | Compensation Wire Rope Market |

| Accounted market size in year | US$ 363 million |

| Forecasted market size in 2031 | US$ 503 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teufelberger-Redaelli, ArcelorMittal, Haggie, IPH Global, Kiswire, Bridon-Bekaert, DSR Wire, Gustav Wolf, Brugg, Dipa Steel Rope, Jiangsu Shenwang, Guizhou Wire Rope, BOMCO Steel Tube &Wire Rope, Juli Sling, Goldsun, Shanghai Junwei Steel Rope, Hubei Fuxing, Fasten Steel Rope |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |